Total internal reflection lens design method for custom lighting

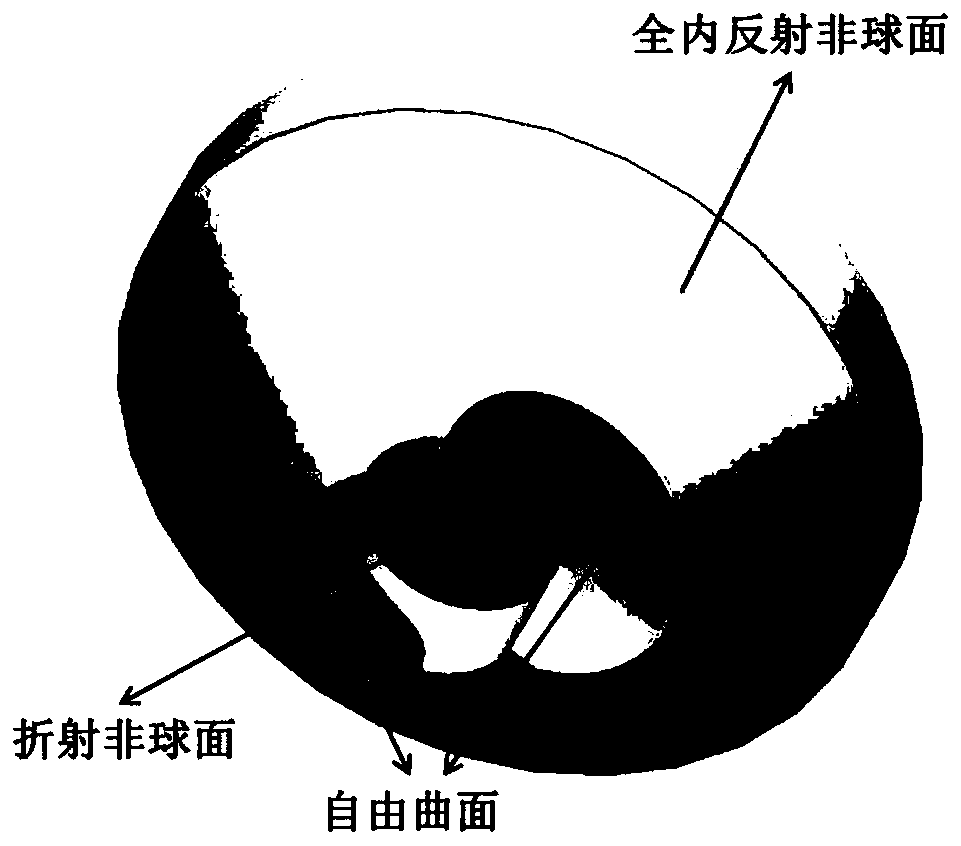

A total internal reflection lens and total internal reflection technology, applied in the field of total internal reflection lens design, can solve the problems of not being able to generate uniform light spots, generating irradiance, and being unable to meet the complex needs of custom lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention is further described below through specific examples.

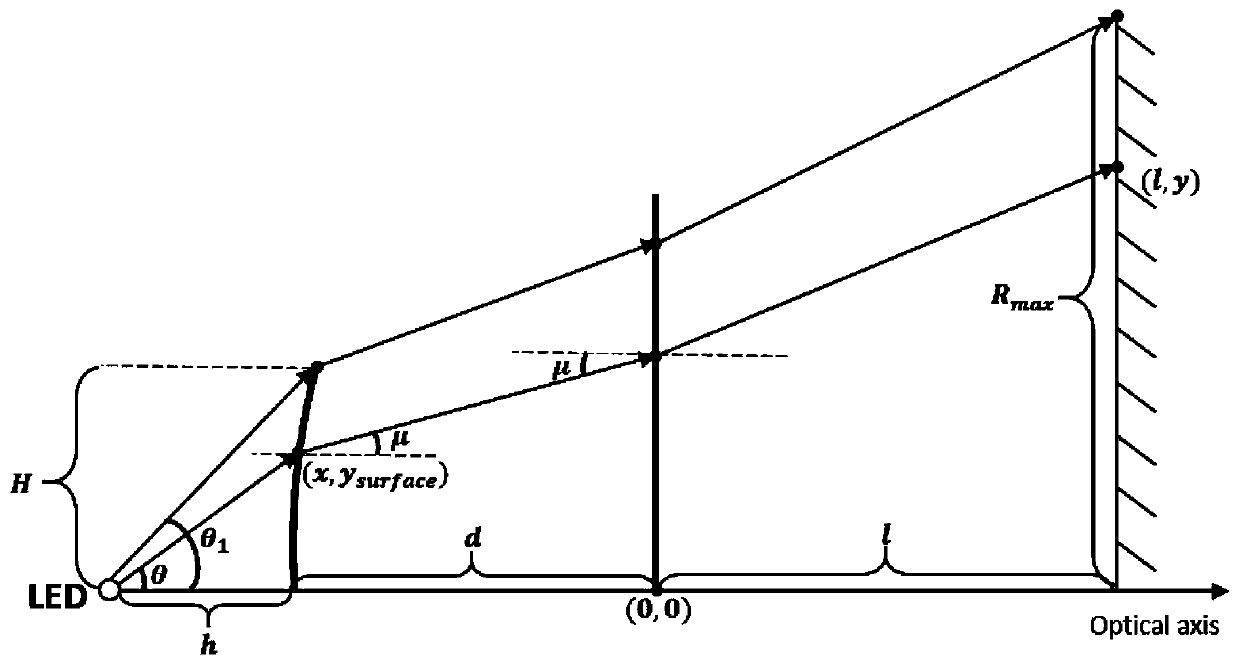

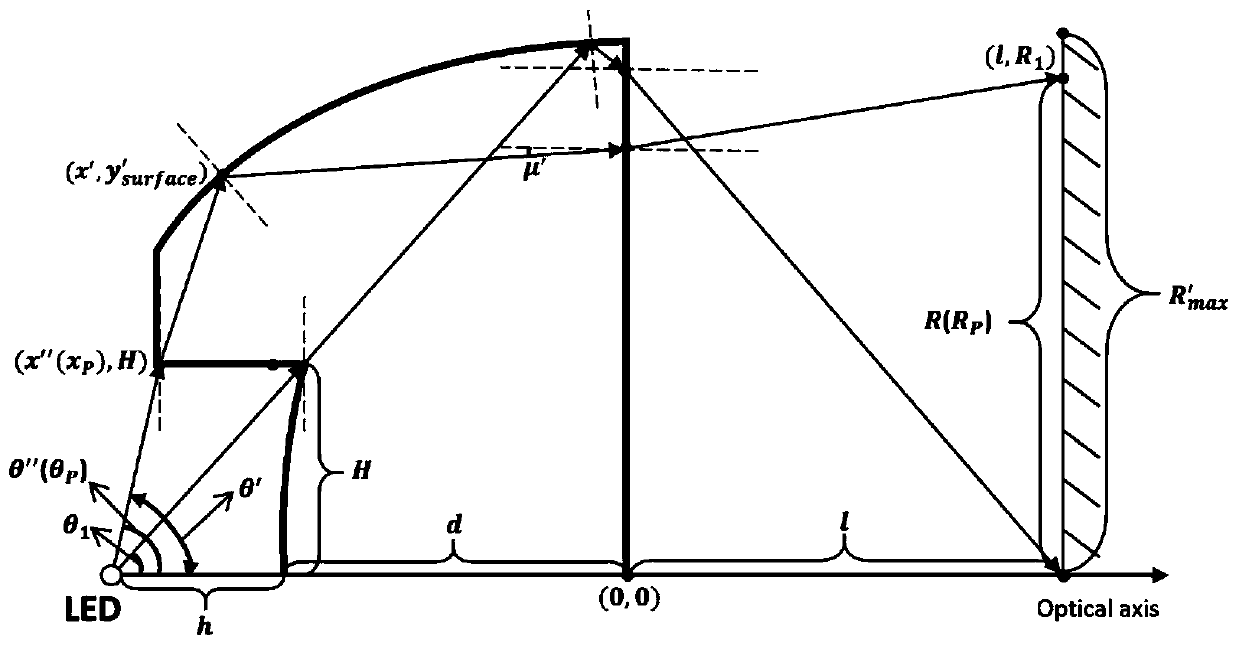

[0062] (1) Schematic diagram of the structure of the refractive aspheric surface as shown in figure 2 As shown, first determine the uniform spot radius R generated by the LED light on the target surface after being adjusted by the refraction aspheric surface according to the design requirements max =1000mm, irradiation distance l=1000mm, lens refractive index n=1.643, lens center thickness d=10mm, LED maximum emission half angle θ max =π / 2rad and the distance between the LED and the lens center h=5mm and other conditions, assuming that the abscissa of any point on the refraction aspheric surface to be solved is x, and the ordinate is y surface , based on the geometric relationship between the LED and the refracting aspheric surface, the luminous flux conservation formula and Snell's law, a set of DAEs is derived. The specific process is:

[0063] According to the conservation of luminous fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com