Discharge lamp for vehicle

A technology for discharge lamps and vehicles, applied to discharge lamps, gas discharge lamps, high-pressure discharge lamps, etc., can solve problems such as deterioration of light distribution characteristics, achieve the effects of ensuring light distribution performance, good light distribution performance, and suppressing temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments for carrying out the discharge lamp for vehicles of the present invention will be described with reference to the drawings. The vehicle discharge lamp has a vehicle headlamp.

[0036] The vehicle headlamp 1 is mounted on both left and right ends of the front end of the vehicle body.

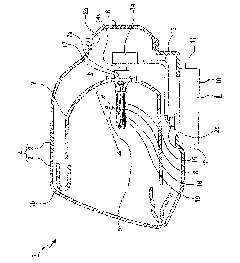

[0037] Such as figure 1 As shown, the vehicle headlamp 1 includes: a lamp housing 2 and a cover 3, the lamp housing 2 has a recess opening at the front, the cover 3 blocks the opening surface of the lamp housing 2, and the lamp housing 2 The body 2 and the cover 3 constitute the outer frame 4 of the lamp. The inner space of the lamp frame 4 is formed as a lamp chamber 5 .

[0038] A rear end portion of the lamp housing 2 is formed with an insertion hole 2 a penetrating front and rear, and the insertion hole 2 a is closed by a rear cover 6 . The lower end portion of the lamp housing 2 is formed with an arrangement hole 2b penetrating vertically.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com