Method for generating gum penetrating surface of dental implant abutment

A dental abutment and gingival penetration technology, applied in image data processing, 3D modeling, instruments, etc., can solve problems such as obvious edges and corners, deviation of the gingival surface model, and low controllability of the gingival surface shape. , to achieve the effect of efficient lofting, simple lofting and simple grid stitching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] With reference to accompanying drawing, further illustrate the present invention:

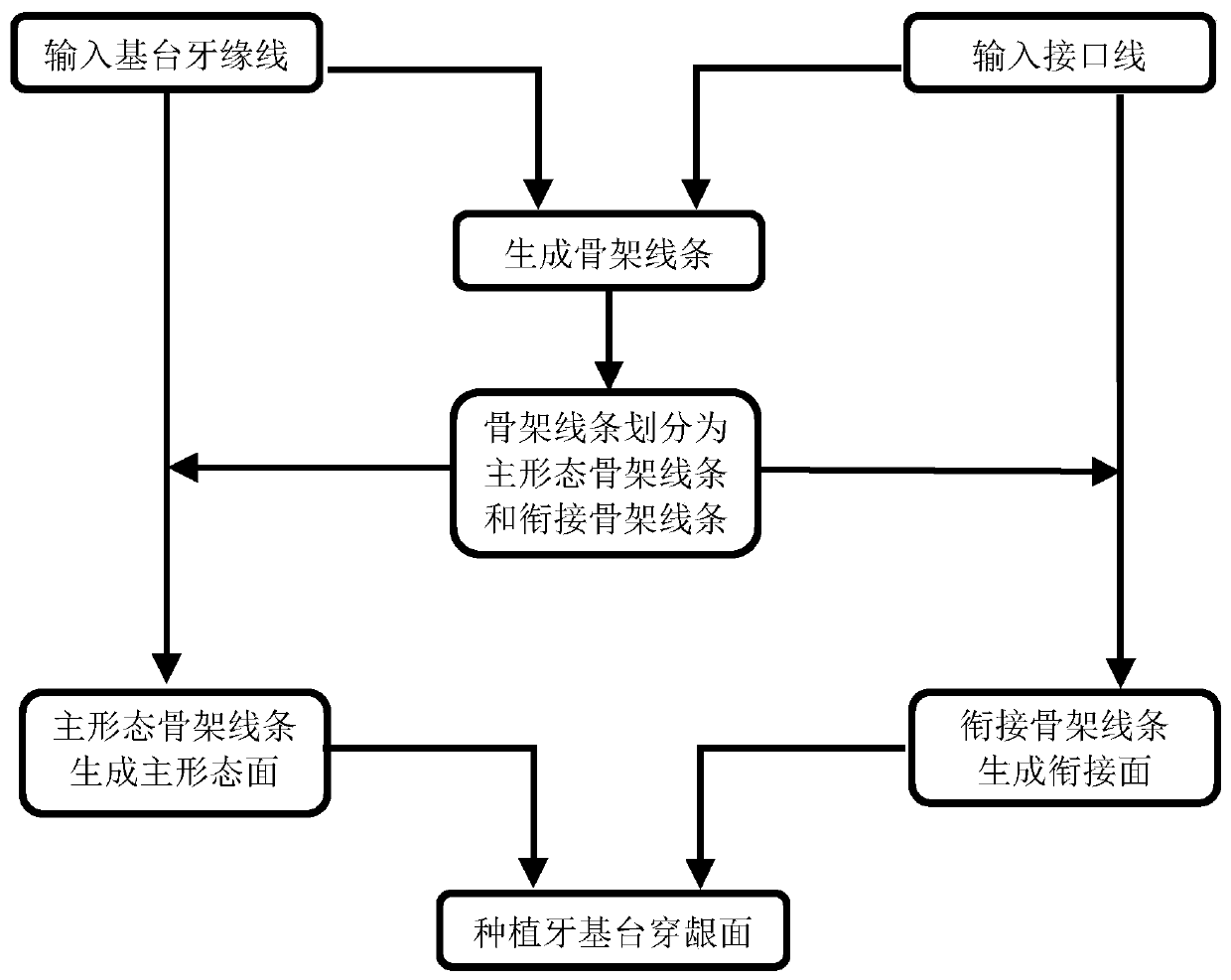

[0017] A method for generating a dental implant abutment through a gingival surface, comprising the following steps:

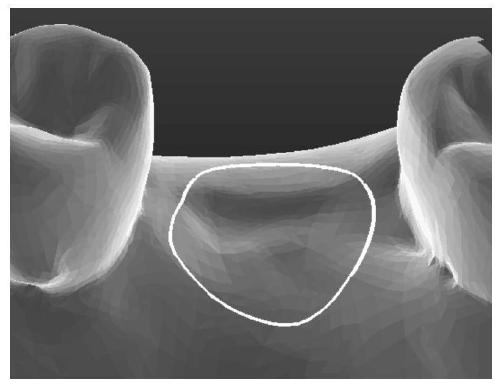

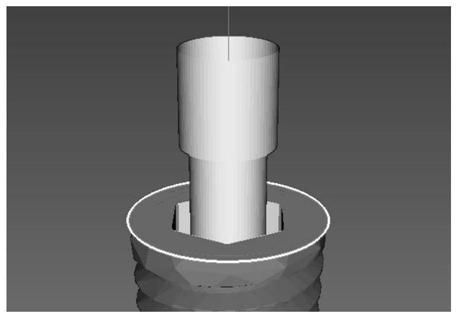

[0018] Step 1. Obtain the input abutment gingiva line L 1b and interface line L 2p , the concave-convex shape of the transgingival surface is determined by the parameters set by the user, and the method of creating lines in equal proportions is used to create L 1b and L 2p The skeleton lines between.

[0019] Step 2. Divide the skeleton lines generated in step 1 into two parts, close to the interface line L 2p The linking skeleton line part S L1 Contains 2 curves, near the abutment gingiva line L 1b The main shape skeleton line part S L2 Contains most other curves.

[0020] Step 3. Connect the skeleton line S separated in step 2 L1 and main shape skeleton line S L2 Each stake out as a surface, S L1 Partial use of simple lofts for connecting surfaces M 1u , S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com