Filtering device for air purification equipment

A technology of air purification equipment and filter devices, which is applied in the direction of combined devices, dispersed particle filtration, transportation and packaging, etc., which can solve the problems of high maintenance frequency, unfavorable use, and increased maintenance costs, so as to reduce maintenance frequency, reduce moisture, and maintain Easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

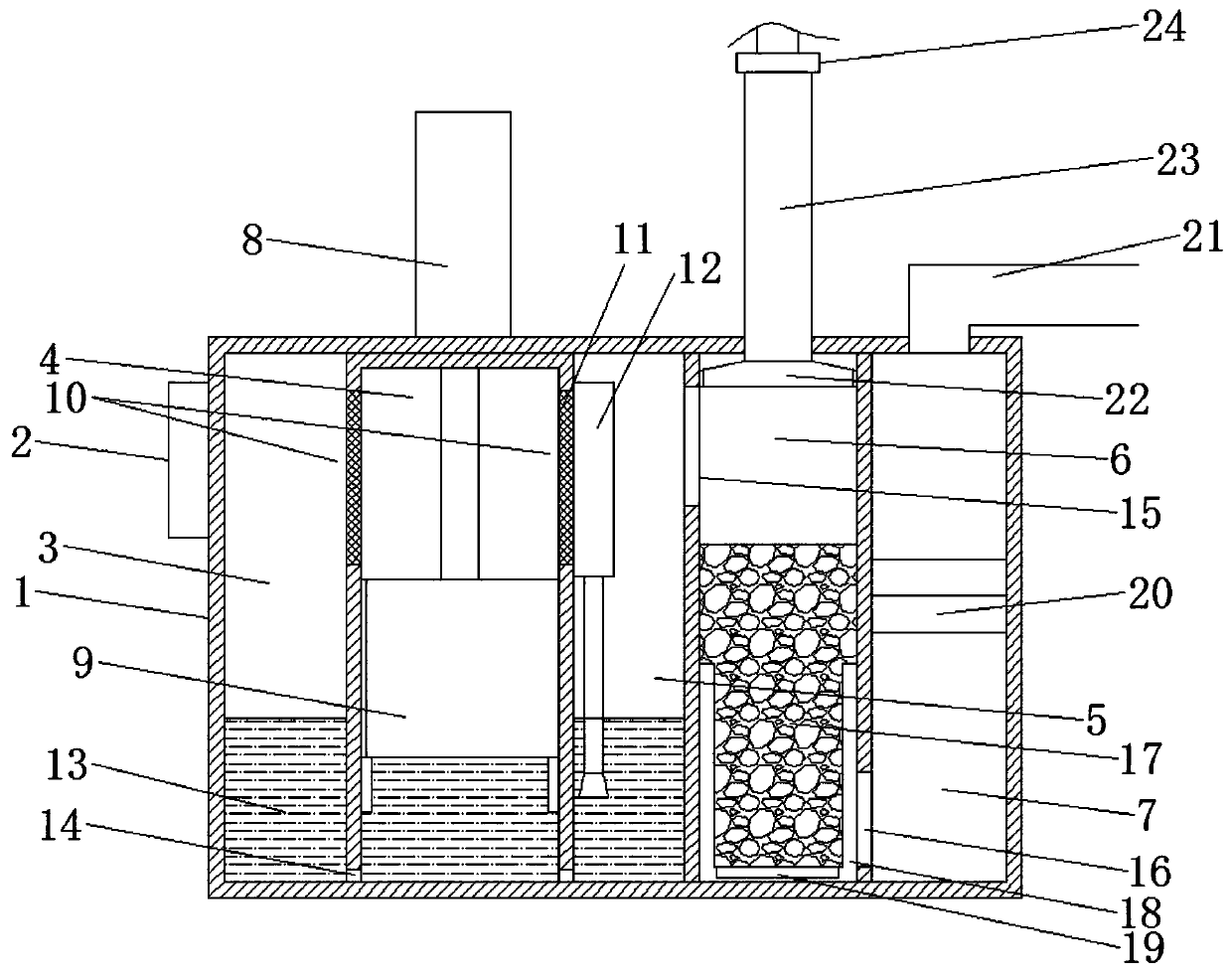

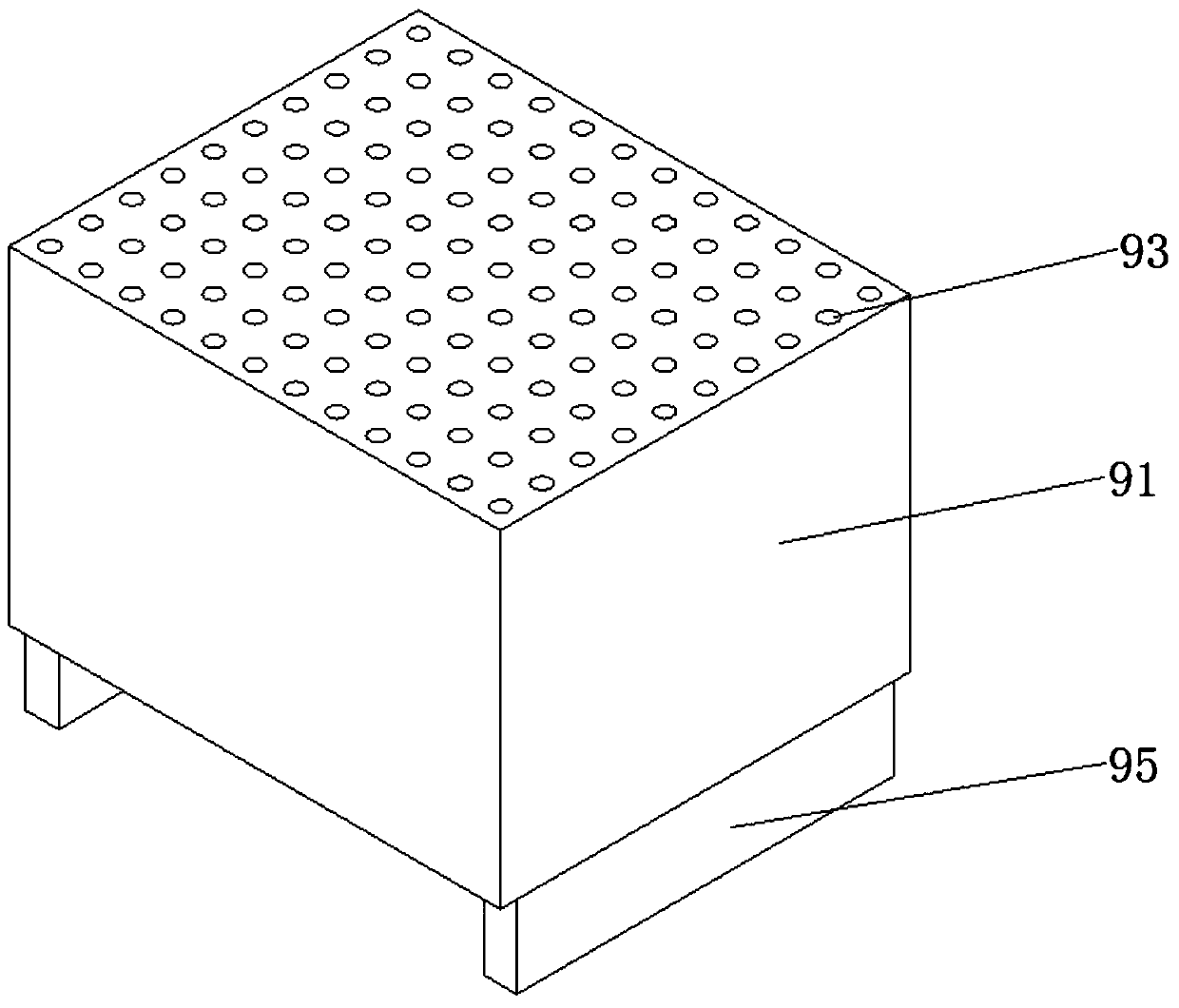

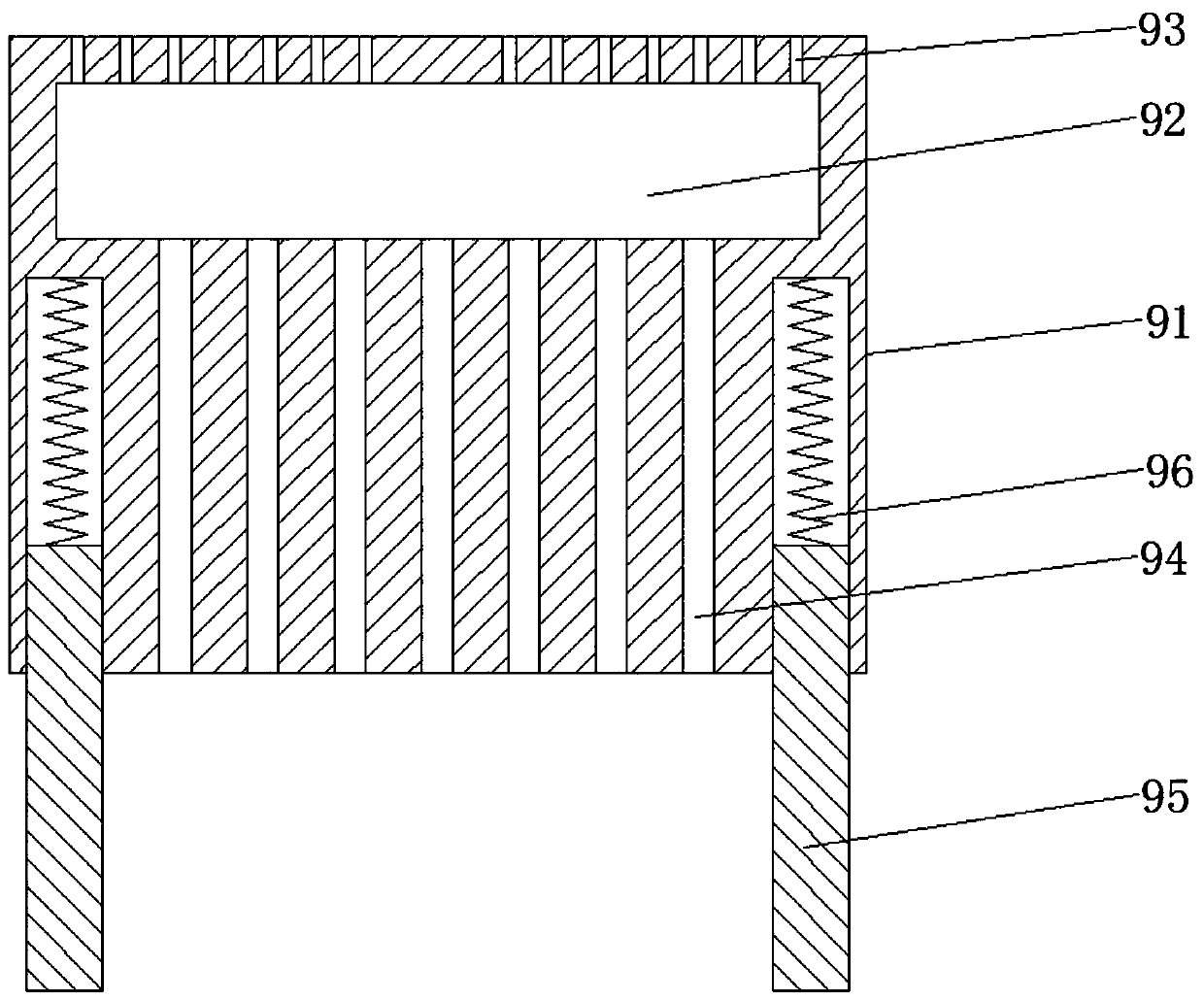

[0022] Please refer to the figure, in an embodiment of the present invention, a filter device for air purification equipment includes a housing 1, a blower 2, a cylinder 8 and an air outlet pipe 21; the housing 1 is separated from left to right by a partition plate into The first water chamber 3 , the extrusion cleaning chamber 4 , the second water chamber 5 , the drying chamber 6 and the fine filter chamber 7 .

[0023] The side wall of the first water chamber 3 is communicated with a blower 2 to send the external air into the shell 1; the bottom between the first water chamber 3 and the extrusion cleaning chamber 4, the extrusion cleaning chamber 4 and the The bottoms between the second water chambers 5 are communicated through several openings 14. Cleaning water 13 is filled in the first water chamber 3, the extrusion cleaning chamber 4, and the second water chamber 5. The first water chamber 3, extrusion cleaning The cavity 4 and the second water cavity 5 are filled with c...

Embodiment 2

[0029] On the basis of embodiment 1, the bottom in the described drying chamber 6 is fixedly installed with a heating element 19 for heating above, and the heating element 19 heats the pipe, and the heating oil is passed inside to increase the temperature in the drying chamber 6. When cleaning, the drying chamber 6 is heated, and the moisture in the drying packing 17 is evaporated and taken away. On the top of the drying chamber 6, a dehumidification wind cover 22 is installed, and the dehumidification wind cover 22 is slidably connected on the inner wall of the drying chamber 6. Move down to the dry filler 17, so that the generated water vapor directly enters the dehumidification wind cover 22, and the dehumidification wind cover 22 is connected with a dehumidification pipe 23, and a valve 24 is installed on the dehumidification pipe 23. When cleaning, open the valve 24 to discharge water vapor . The dry packing 17 in the drying chamber 6 is maintained to prolong its service ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com