Magnesium-containing ore desulfurization and denitrification slurry and synchronous desulfurization and denitrification method

A technology for desulfurization and denitrification, magnesium ore, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems that have not yet been reported on simultaneous wet desulfurization and denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In the present invention, there is no special limitation on the preparation method of the magnesium-containing ore particles, as long as the magnesium-containing ore particles with the required particle size can be obtained. In the embodiment of the present invention, the preparation method of the magnesium-containing ore particles preferably includes the following steps :

[0024] The raw materials for preparing the magnesium-containing ore are sequentially crushed and ball-milled to obtain magnesium-containing ore particles.

[0025] In the present invention, there is no special limitation on the particle size, crushing and ball milling methods of the raw materials for the preparation of the magnesium-containing ore, as long as the magnesium-containing ore particles with the required particle size can be obtained. In the embodiment of the present invention, the degree of crushing is preferably based on the absence of lumpy materials; the rotational speed of the ball m...

Embodiment 1

[0035] (1) Preparation of magnesium-containing ore desulfurization and denitrification slurry:

[0036] The magnesite (magnesium content is 26.89wt%) is crushed into a lump-free material, and then ball milled into magnesite particles with a D90 of 75 μm; the specific parameters of the ball mill are that the ball-to-material ratio is 1:1, and the speed is 480rpm ;The ball milling time is 15min;

[0037] Mix magnesite particles, sodium chlorite and water to obtain magnesium-containing ore desulfurization and denitrification slurry, wherein the solid-to-liquid ratio of the magnesium-containing ore desulfurization and denitrification slurry is 1:20 by mass ratio, and the concentration of sodium chlorite is 10mmol / L;

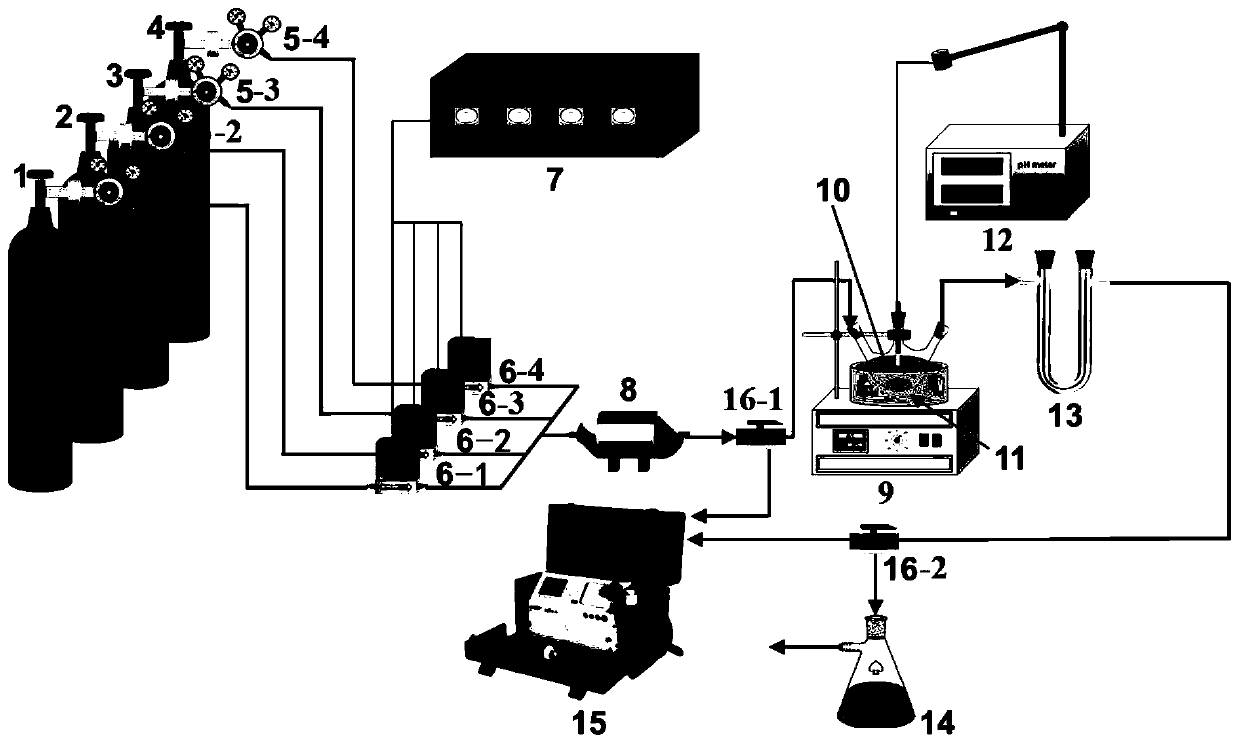

[0038] (2) use figure 1 The device shown in this example tests the desulfurization and denitrification performance of the magnesium-containing ore desulfurization and denitrification slurry, specifically: put 200 mL of the magnesium-containing ore desulfurization an...

Embodiment 2

[0040] (1) Preparation of magnesium-containing ore desulfurization and denitrification slurry:

[0041] The phosphate rock (magnesium content is 0.55wt%) is crushed into a lump-free material, and then ball milled into phosphate rock particles with a D90 of 75 μm; the specific parameters of the ball mill are that the ball-to-material ratio is 1.5:1, and the rotating speed is 500rpm; The time is 15 minutes;

[0042] Mix phosphate rock particles, sodium chlorite and water to obtain magnesium-containing ore desulfurization and denitrification slurry, wherein the solid-to-liquid ratio of the magnesium-containing ore desulfurization and denitrification slurry is 1:10 by mass ratio, and the concentration of sodium chlorite is 15mmol / L;

[0043] (2) use figure 1 The device shown in this example tests the desulfurization and denitrification performance of the magnesium-containing ore desulfurization and denitrification slurry, specifically: put 200 mL of the magnesium-containing ore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com