Flue gas purification device capable of efficiently desulfurizing and denitrifying and implementation method of flue gas purification device

A technology for desulfurization, denitrification, and flue gas purification, which is applied in the field of flue gas purification. It can solve problems such as failure to meet emission standards, poor desulfurization effect, and inability to perform a large amount of demisting, so as to save denitrification time, ensure denitrification effect, and increase uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

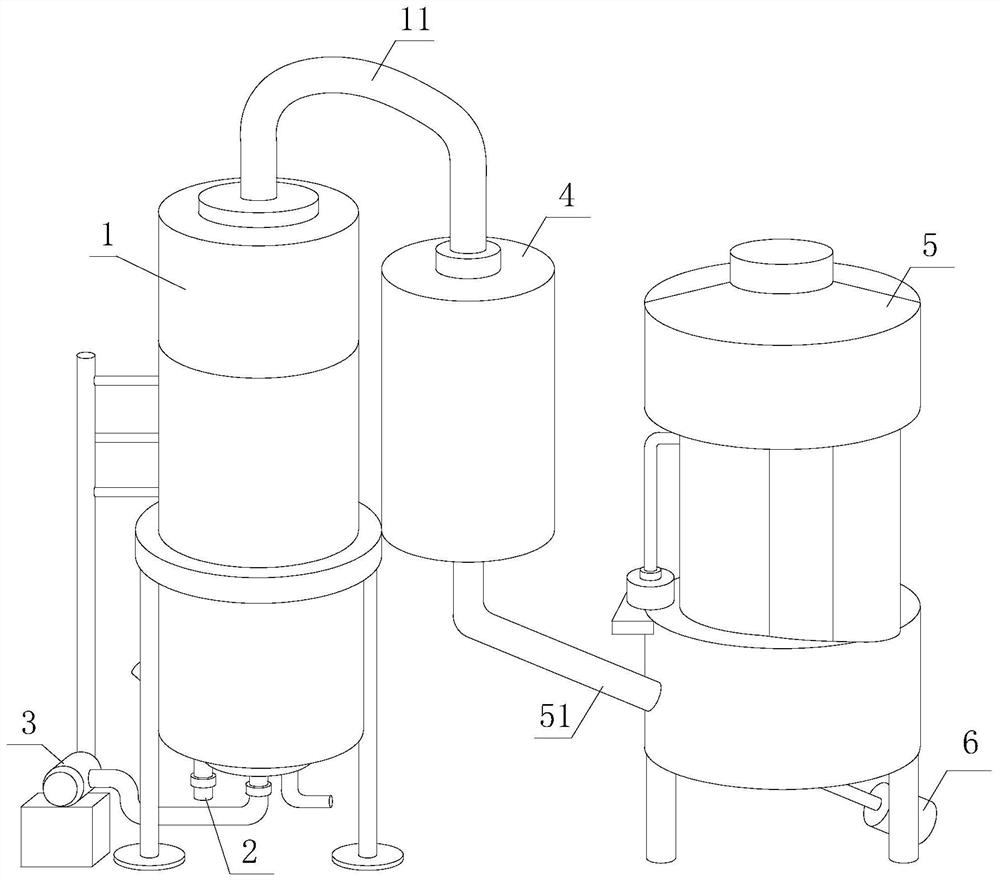

[0044] In order to better demonstrate the implementation process of a flue gas purification device capable of achieving high-efficiency desulfurization and denitration, this embodiment proposes an implementation method of a high-efficiency desulfurization and denitrification flue gas purification device, including the following steps:

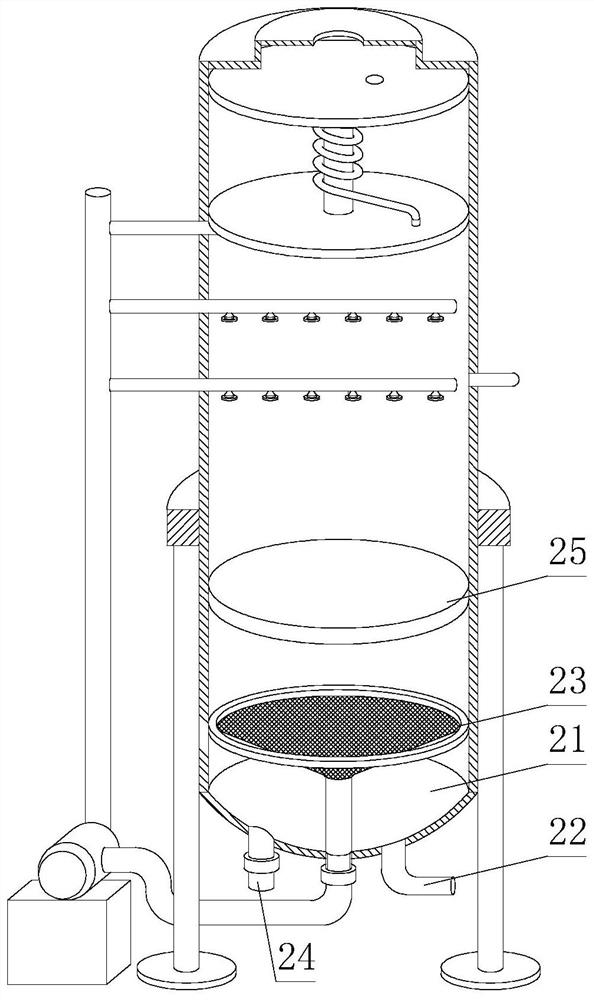

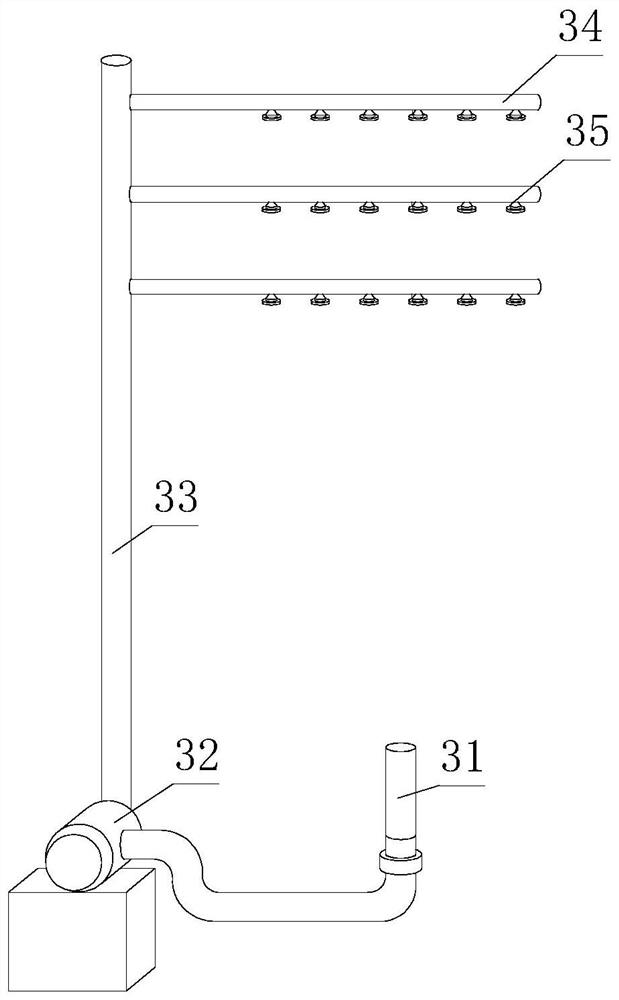

[0045] Step 1: The flue gas is transported into the reaction chamber 21 first, mixed with the ammonia gas in the reaction chamber 21, and the gas after the mixed reaction is filtered by the inverted conical filter plate 23, and the gas connection pipe 31 will be inverted. The gas filtered by the shaped filter screen plate 23 is delivered to the denitrification tank 1, and sprayed out in a dispersed manner through the nozzle 35 to ensure the uniformity of mixing;

[0046] Step 2: When the mixed gas passes through the delivery elbow 122, it is heated by the heating column 121 and transported into the catalytic tank 41, and the heated gas fully rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com