Disc mill capable of automatically cleaning

An automatic cleaning and pulverizer technology, which is applied in cocoa, grain processing, food science, etc., can solve the problems that disc pulverizers cannot automatically adjust the gap, manual manual feeding is uneven, and cannot automatically feed, etc., to achieve environmental benefits The effect of protection, high degree of automation, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiment of the present invention will be illustrated in detail below in conjunction with the accompanying drawings, but the preferred embodiment cannot be used to limit the protection scope of the present invention.

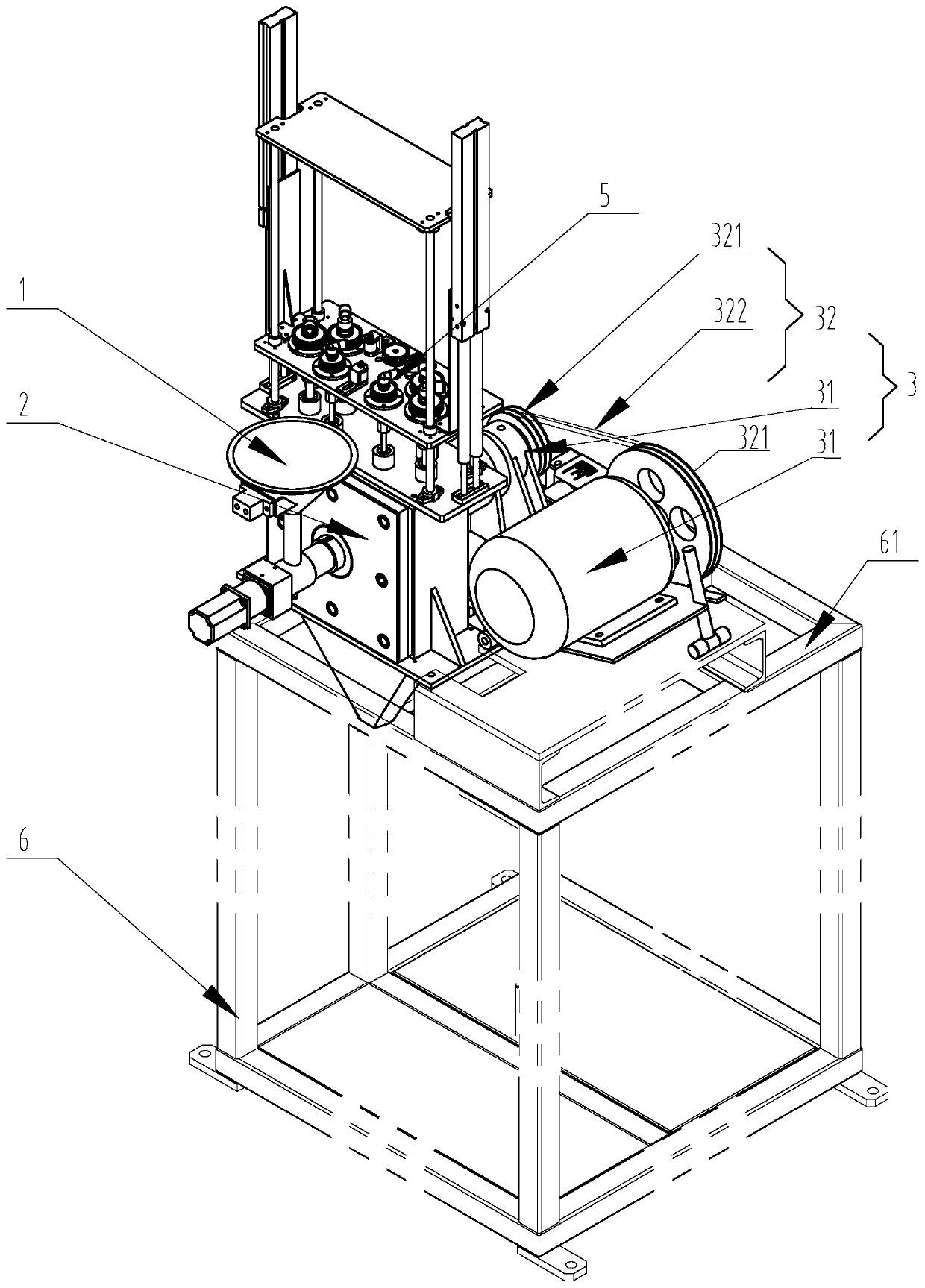

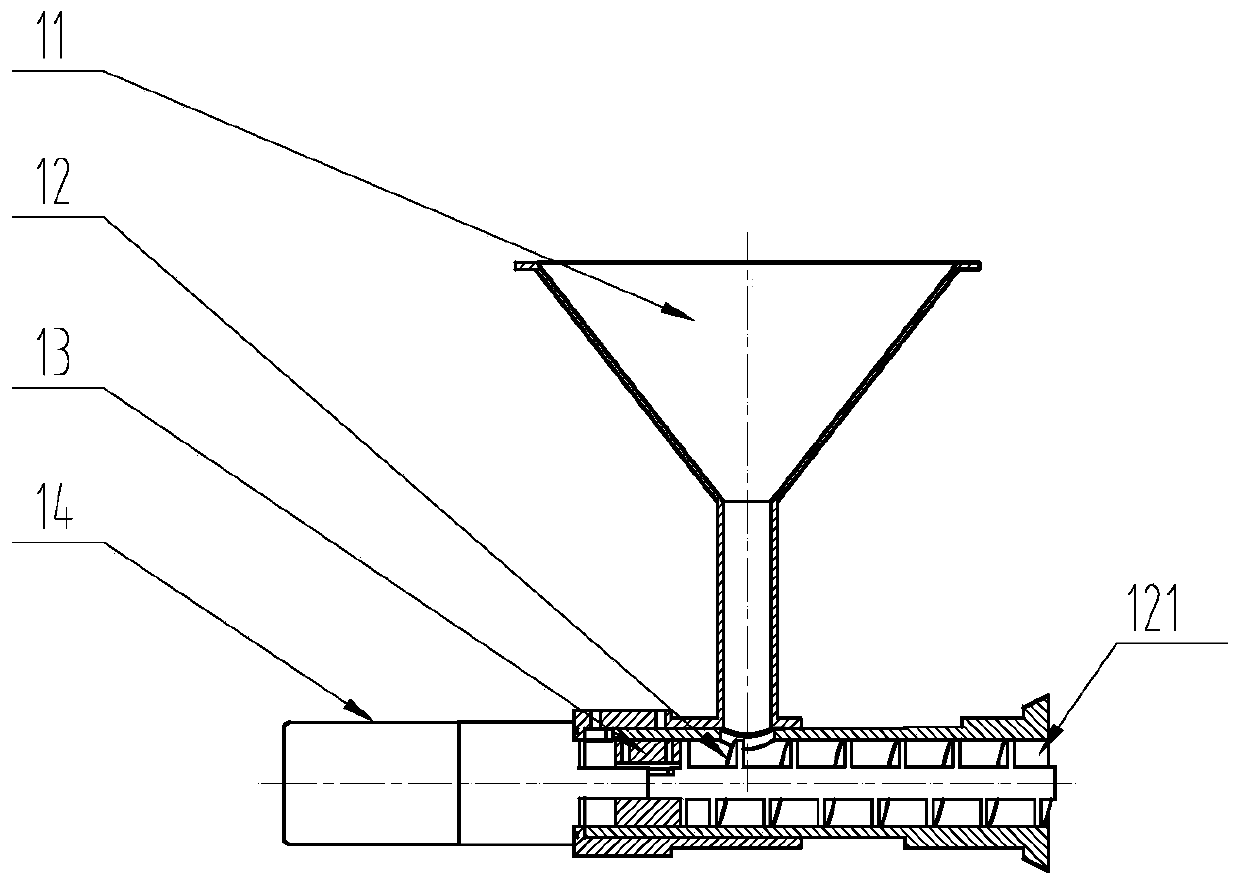

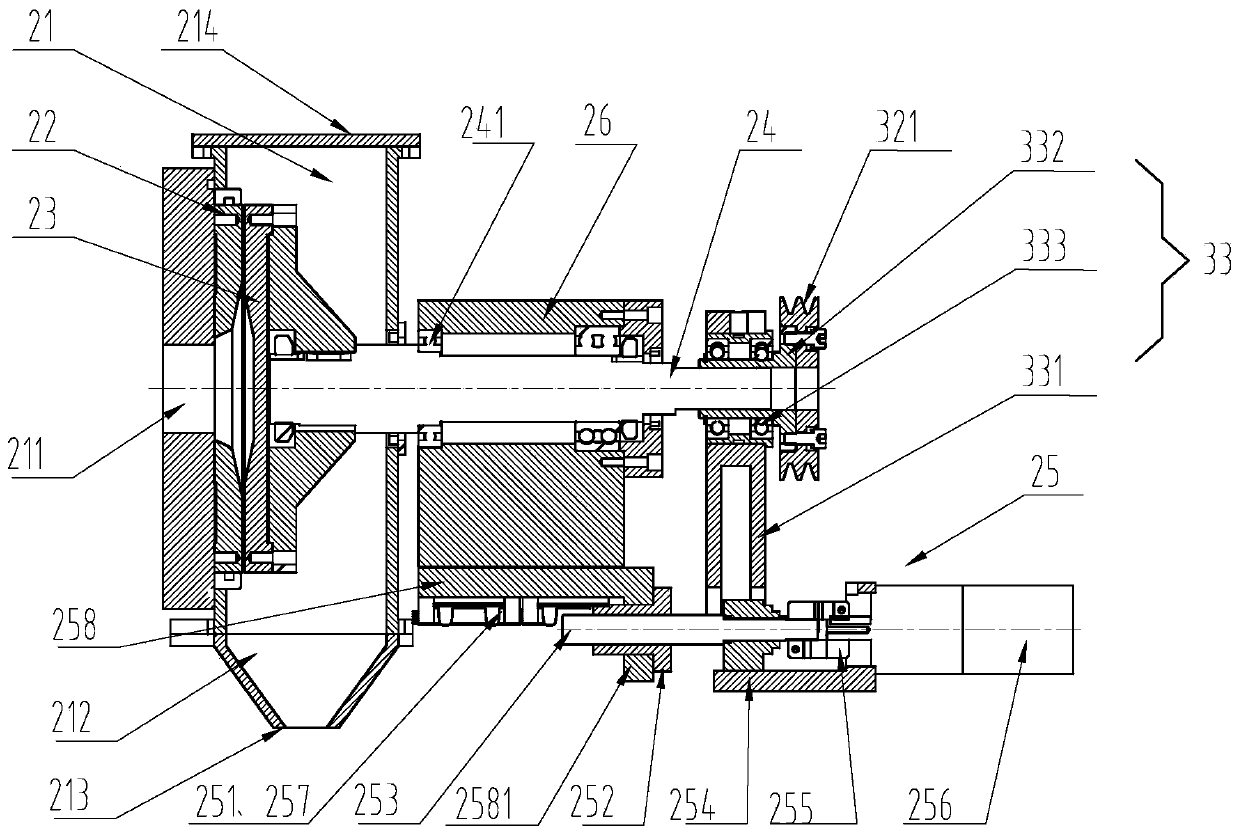

[0033] Such as figure 1 As shown, the present invention provides a disc grinder that can be cleaned automatically, which includes a grinding mechanism 2, which includes a grinding chamber 21 with a feed port 211 and a discharge port 213, at the feed port 211 One side, the grinding chamber 21 are provided with a static grinding disc 22 with a center hole, and a moving grinding disc 23 is arranged at an interval relative to the static grinding disc 22. The moving grinding disc 23 is connected to the power mechanism 3 by a rotating shaft 24 and can rotate; that is, the rotating shaft 24 The front end extends into the grinding chamber 21 and is provided with a movable grinding disc 23; the rear end is connected to the power mechanism 3 outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com