Mechanical finger based on magnetorheology, and mechanical finger drive method

A mechanical finger and magneto-rheological technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of easily damaged objects, poor protection effect of mechanical fingers, poor gripping stability of mechanical fingers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment discloses a mechanical finger based on magnetorheology.

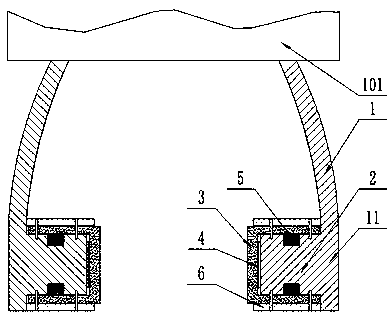

[0046] Such as figure 1 Shown: a mechanical finger based on magnetorheology, including a finger body 1, a drive unit for driving the finger body 1 to apply a clamping force to a target, and a control unit electrically connected to the drive unit;

[0047] The clamping part 11 of the finger body 1 has a contact end facing the target and used to contact the target when in use; the position of the contact end is fixed with a magnetorheological elastic part 3 covering the end surface of the contact end; the magnetorheological elastic part 3 There is a gap fit between the side facing the contact end and the end face of the contact end, and a pressure sensing component 4 connected to the control unit signal is correspondingly provided in the gap between the magneto-rheological elastic part 3 and the contact end; the clamping part 11 An electromagnetic coil assembly 5 electrically connected to the contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com