Device and method for catching and knotting head yarn and tail yarn of yarn spools

A knotting device and yarn bobbin technology, which is applied in the directions of transportation and packaging, electrical components, and delivery of filamentous materials, etc. It can solve the problems of high labor costs, inability to truly realize intelligent manufacturing of the production line, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

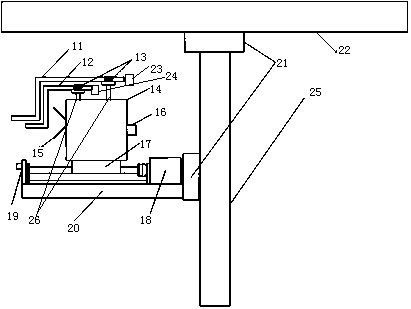

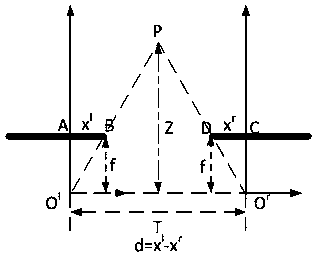

[0031] Below in conjunction with accompanying drawing, content of the invention will be further described:

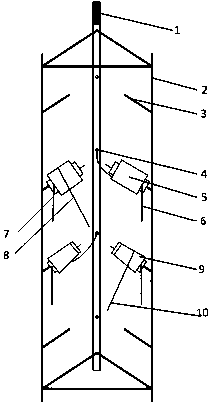

[0032] The schematic diagram of the creel structure is as follows: figure 1 As shown, it is the most common and commonly used triangular air duct creel in the weaving of circular knitting machines.

[0033] In the bobbin yarn capture device, the figure 1 The creel on the left is defined as position A, and the creel on the right is position B. The specific structure of each part is described as follows:

[0034] 1 is the yarn guide tube, which is used to introduce the yarn into the circular knitting machine in an orderly manner. In order to meet the needs of textile production, the position of the yarn guide tube can be adjusted.

[0035] 2 is the creel support, which uses a triangular air duct type creel, and uses the stability of the triangular structure to ensure the reliability of the creel during use, while saving floor space and increasing the number of bobbins u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com