Anti-reverse tooling for lifting station and anti-reverse method thereof

A technology of tooling and limit pins, which is applied in the direction of hoisting devices, springs/shock absorbers, vibration suppression adjustments, etc., and can solve the problem that the equipment cannot be dropped in one direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

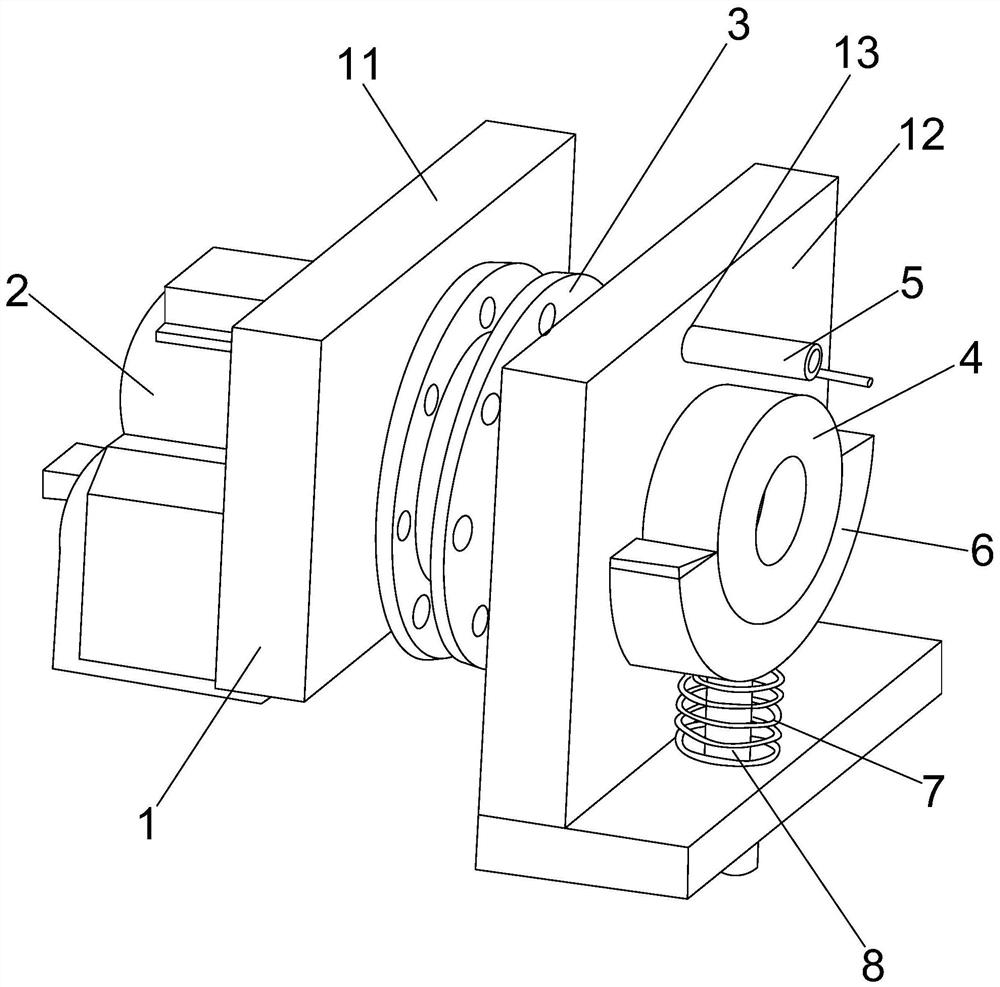

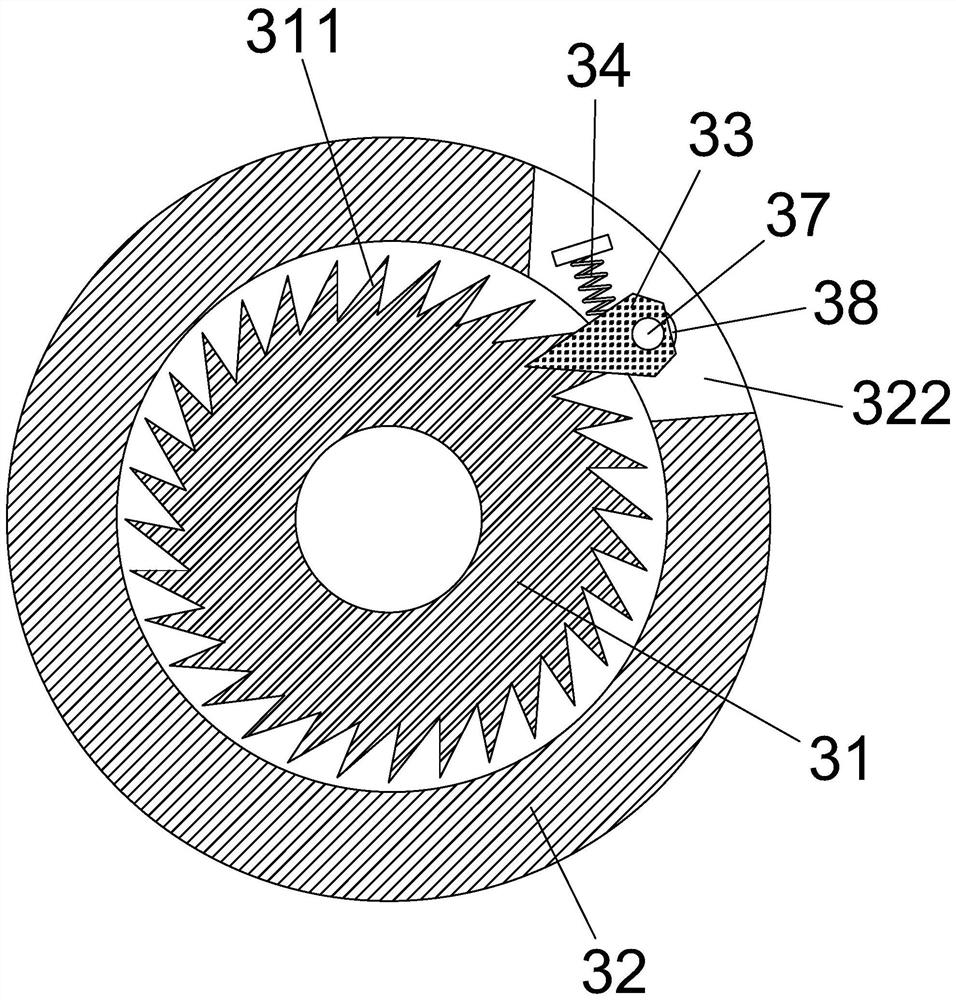

[0056] see figure 1 , figure 2 as well as image 3 , this embodiment provides an anti-reversal tooling for a lifting station, the tooling includes a base 1, a motor 2, a lifting plate 3 and a one-way bearing 4, and may also include a positioning pin 5, a positioning component 6, a shock absorber Spring 7 and limit bar 8. Among them, the base 1, the motor 2 and the one-way bearing 4 can all use existing related components, that is, the tooling of this embodiment can be modified, added or replaced on the basis of the existing tooling.

[0057] In this embodiment, the base 1 includes a first mounting block 11 and a second mounting block 12 . There is an installation space for accommodating the rotation of the suspension force plate 3 between the first installation block 11 and the second installation block 12 . Motor 2 is installed on the installation block one 11, and one-way bearing 4 is installed on the installation block two 12. Both the first installation block 11 and ...

Embodiment 2

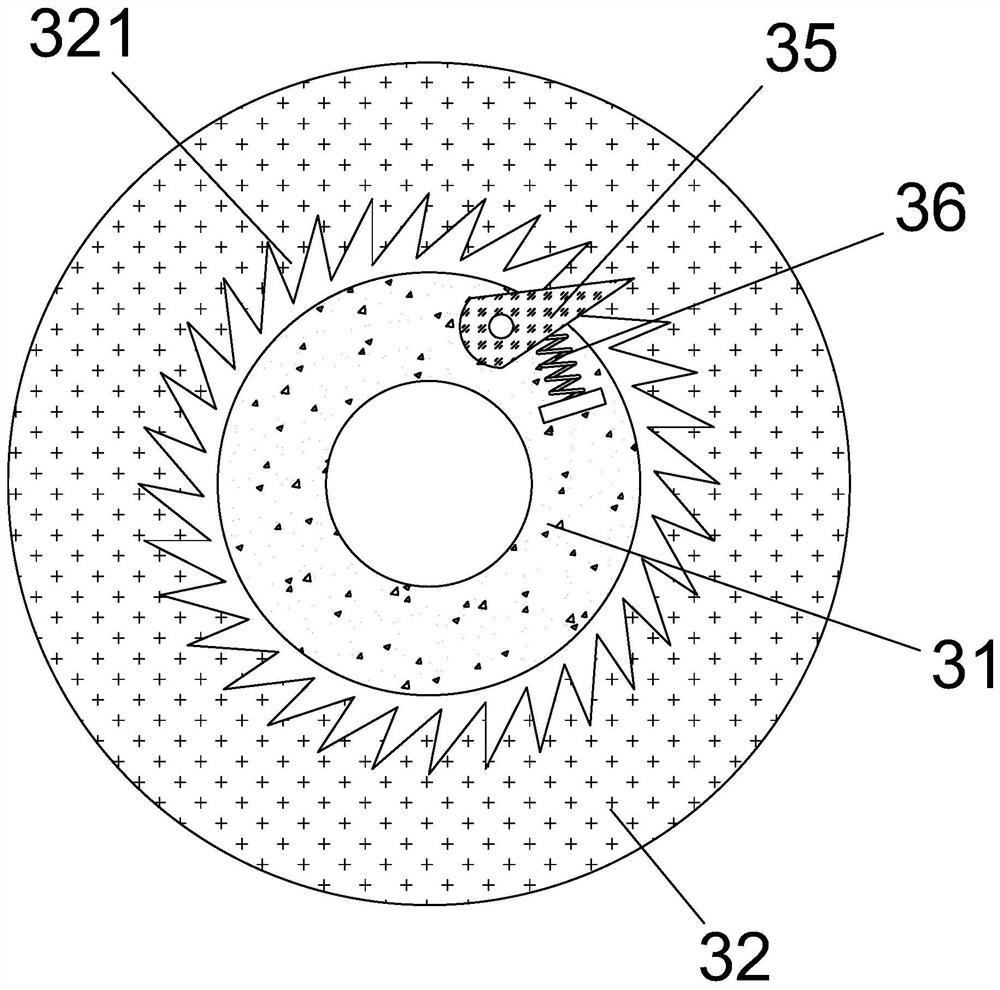

[0079] This embodiment provides an anti-reversal tooling for the lifting force station, which is similar to the tooling of Example 1, the difference is that there are more than one set of limiting pins 2 35 and elastic members 2 36 of the limiting component 2, the minimum for two groups. In this embodiment, each limiting pin 2 35 and its adjacent elastic member 2 36 are set as a group of connection assemblies, and the arrangement of each group of connecting assemblies is the same as that of the limiting pin 2 35 and the elastic member in Embodiment 1. Two 36 are set in the same way, so that when the motor 2 rotates forward, multiple sets of connecting components can provide a more stable driving effect, especially when one of the two limit pins 35 breaks down, other limit pin two 35 can still play a role to the effect. In this way, on the one hand, the anti-rotation can be ensured, and on the other hand, the connection between the inner disc 31 and the outer disc 32 can be ma...

Embodiment 3

[0081] This embodiment provides a lifting station anti-reversal tooling, which is similar to the tooling of Example 1, the difference is that the positioning part 6 in this embodiment is a magnetic structure, that is, a magnetic ring, which can be connected with the one-way bearing 4 The outer ring is magnetically adsorbed. At the same time, only the outer ring of the one-way bearing 4 can be attracted to the positioning component 6 , and other structures cannot be attracted to the positioning component 6 . In this way, the positioning component 6 can conveniently fix the outer ring of the one-way bearing 4 so that the outer ring cannot rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com