Detachable hoop type bridge supporting steel pipe connecting device and method

A technology for supporting steel pipes and connecting devices, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as resource waste, safety risks, and stress concentration of steel pipes, reduce welding workload, facilitate fixed installation, and ensure The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

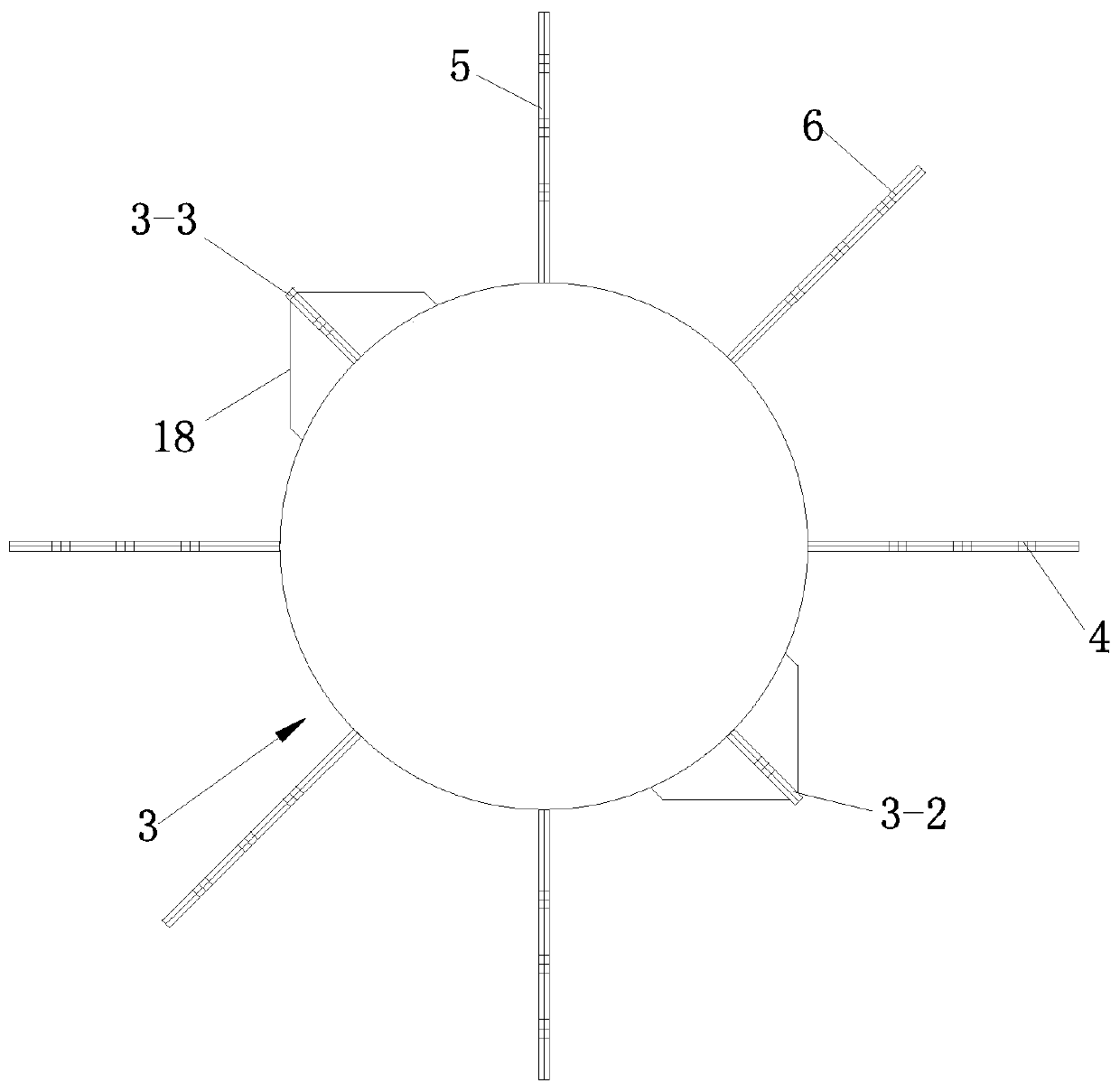

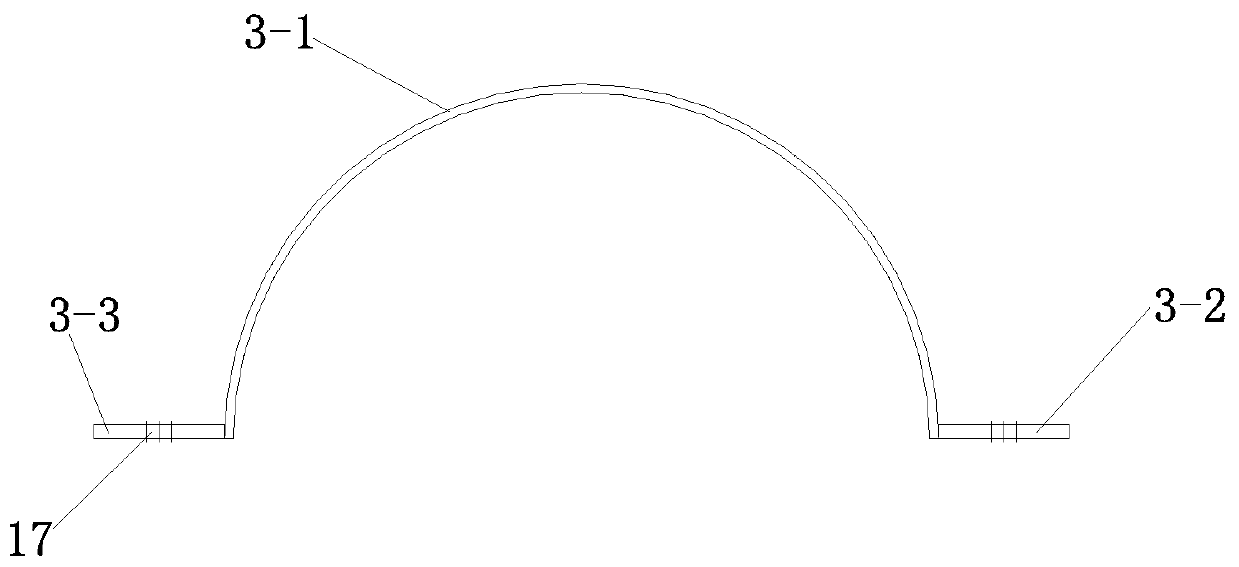

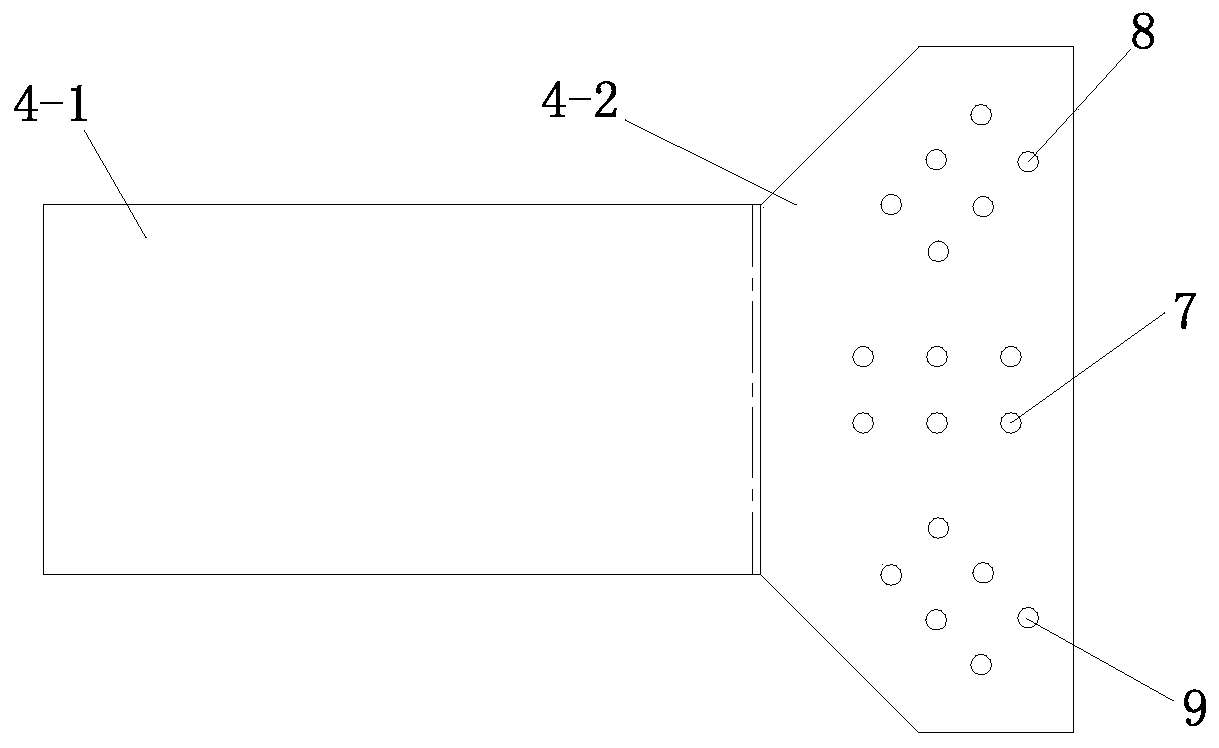

[0055] Such as Figure 1 to Figure 6 The shown detachable hoop-type bridge support steel pipe connection device includes a section steel assembly and a plurality of hoop connection mechanisms arranged on the bridge support steel pipe assembly at equal intervals along the height direction of the bridge support steel pipe assembly. The bridge support steel pipe assembly The assembly includes a plurality of bridge supporting steel pipes 1, and the plurality of bridge supporting steel pipes 1 are arranged in an array. The hoop connection mechanism includes a plurality of hoops 2 arranged in an array. In the hoop connection mechanism, a plurality of hoops The array structure of hoop 2 is the same as the array structure of multiple bridge supporting steel pipes 1, and the hoop 2 is arranged on the outside of bridge supporting steel pipe 1; 2 and the interlayer steel assembly used to connect two adjacent hoop connection mechanisms; in the hoop connection mechanism, a plurality of hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com