A composite flexible support integrated construction method for building deep foundation pit engineering

A construction method and technology of deep foundation pits, which are applied in basic structure engineering, construction, excavation, etc., can solve problems such as low construction efficiency and poor support effect, and achieve the effects of improving construction efficiency, convenient construction, and improving self-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

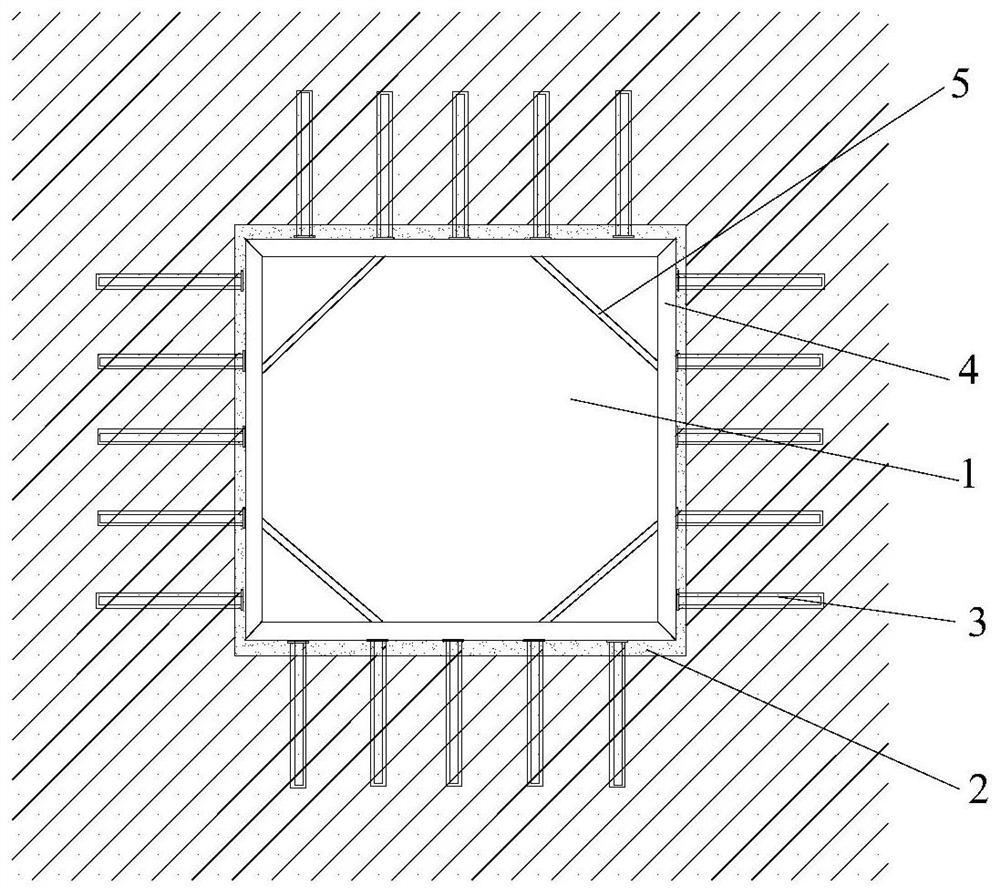

[0033] An integrated construction method of composite flexible support for deep foundation pit engineering provided by the invention comprises the following steps:

[0034] S1, leveling the foundation pit slope 1;

[0035] S2, quickly spray the primary concrete 2 on the slope after step S1 trimming, and seal the foundation pit slope in time;

[0036] S3. After the concrete in step S2 is solidified, drill holes according to the support design requirements, inject cement slurry into the anchor hole, and insert the anchor rod 3;

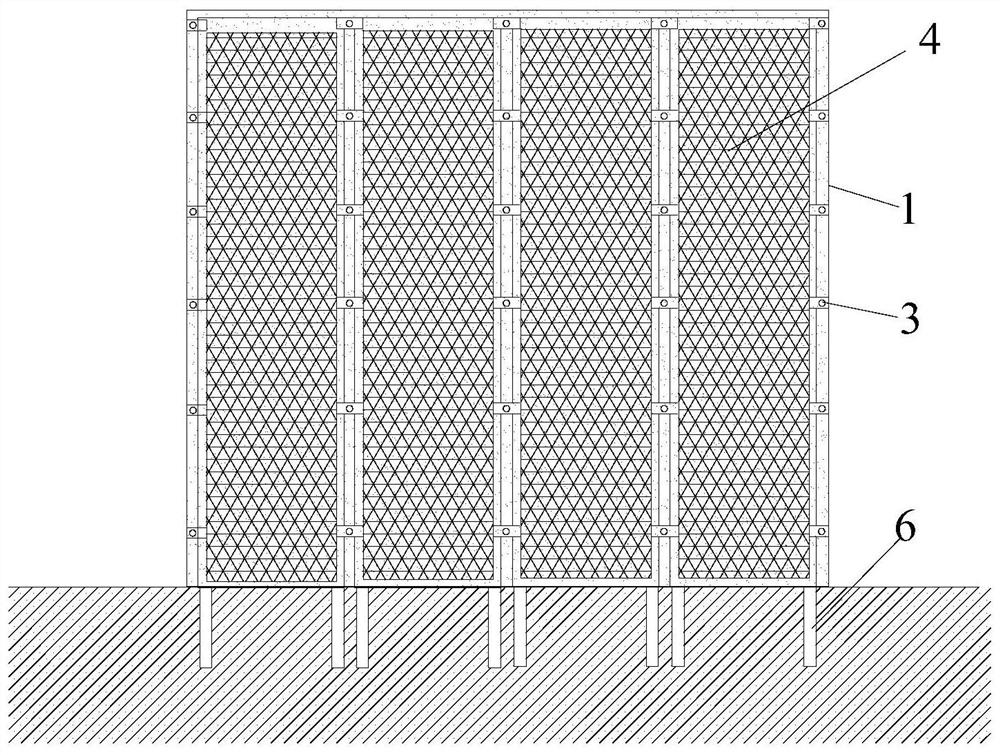

[0037] S4. Install prefabricated steel wire mesh frames 4 on the foundation pit slope 1 after the construction of anchor rods 3 is completed. Two adjacent steel wire mesh frames 4 are connected to the ends of anchor rods 3 through connecting components. The insertion end 6 is reserved, and the insertion end 6 is inserted at the bottom of the foundation pit during construction;

[0038] S5. Secondary spraying of concrete on the installed prefabricated ...

Embodiment 2

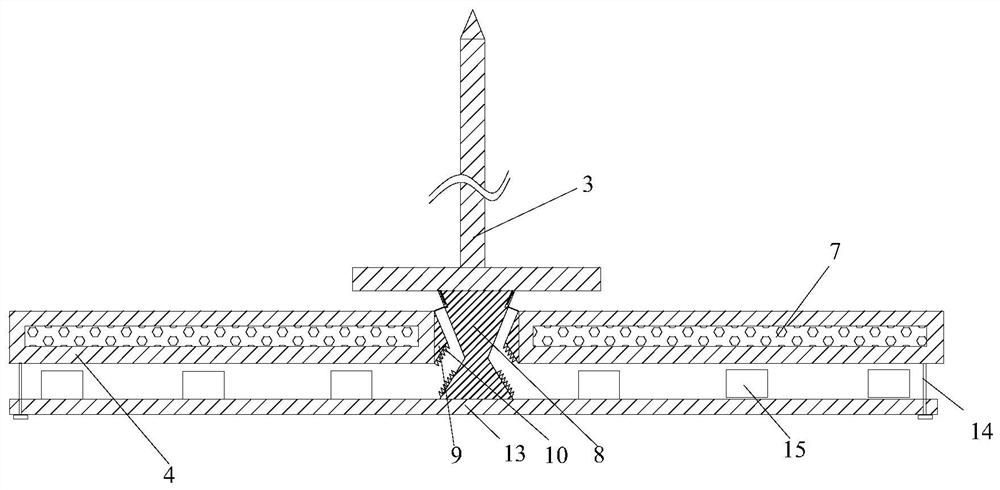

[0040] On the basis of Embodiment 1, in order to enhance the effect of flexible support, the connection assembly of this embodiment includes a butterfly member 8 arranged at the outer end of the anchor rod 3, and the outer edges on both sides of the butterfly member 8 are V-shaped edge, described V-shaped edge comprises first hypotenuse 81 and second hypotenuse 82; The wire mesh frame 4 that is positioned at butterfly member 8 both sides is provided with V-shaped member 9, and the outer edge of V-shaped member 9 includes The third hypotenuse 91 and the fourth hypotenuse 92, the third hypotenuse 91 is slidingly connected with the first hypotenuse 81, the fourth hypotenuse 92 and the second hypotenuse 82 are provided with a set of limit teeth 10, The stop teeth 10 are used to limit the V-shaped member through the stop teeth 10 provided on the fourth bevel 92 and the second bevel 82 after the third bevel 91 slides along the first bevel 81 to the fourth bevel 92 9 slips.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com