Automatic armrest

A handrail and automatic technology, applied in the direction of handrails, building structures, stepped structures, etc., can solve the problems of handrail adsorption and easy falling off, and achieve the effects of not easy falling off, avoiding air leakage, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

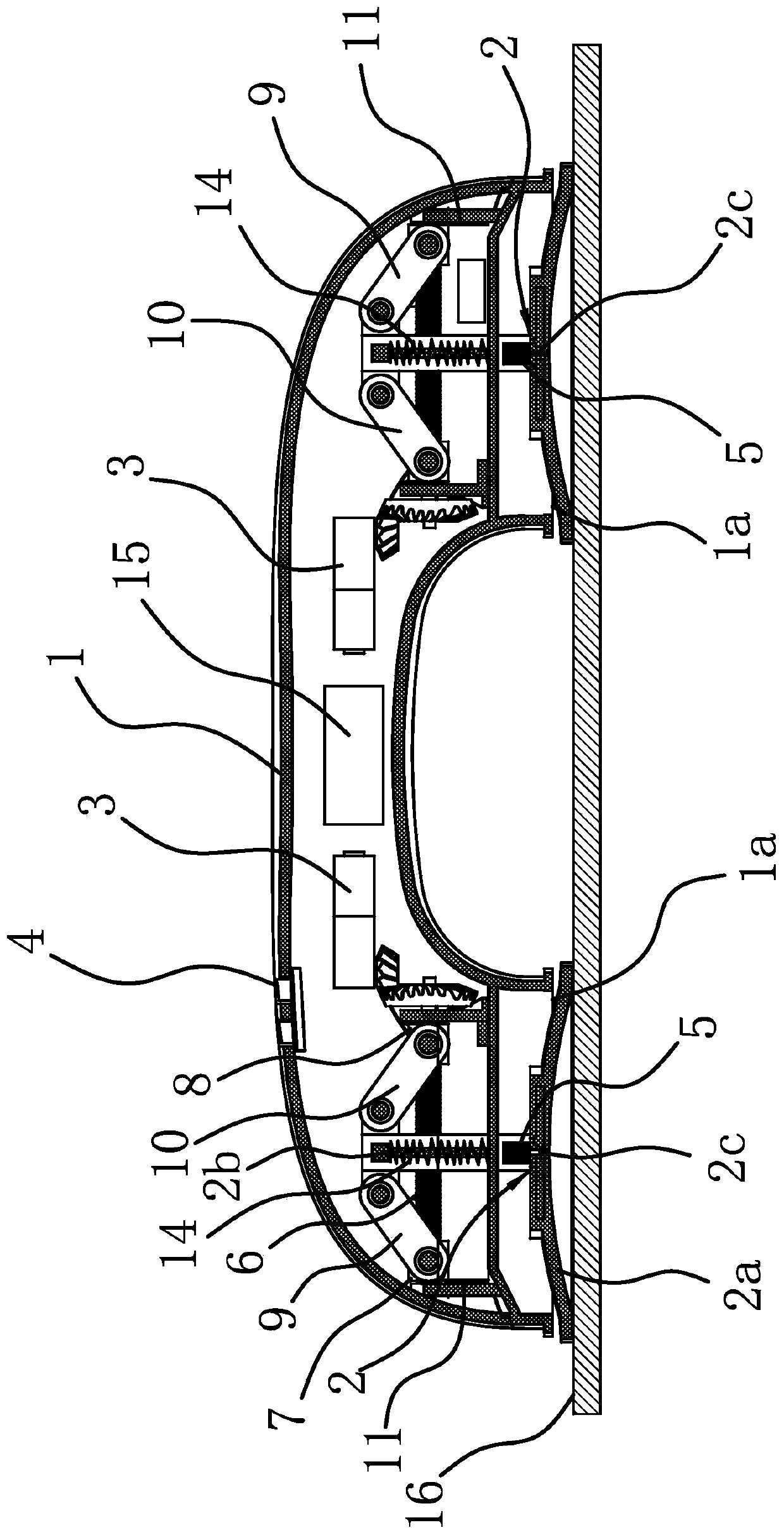

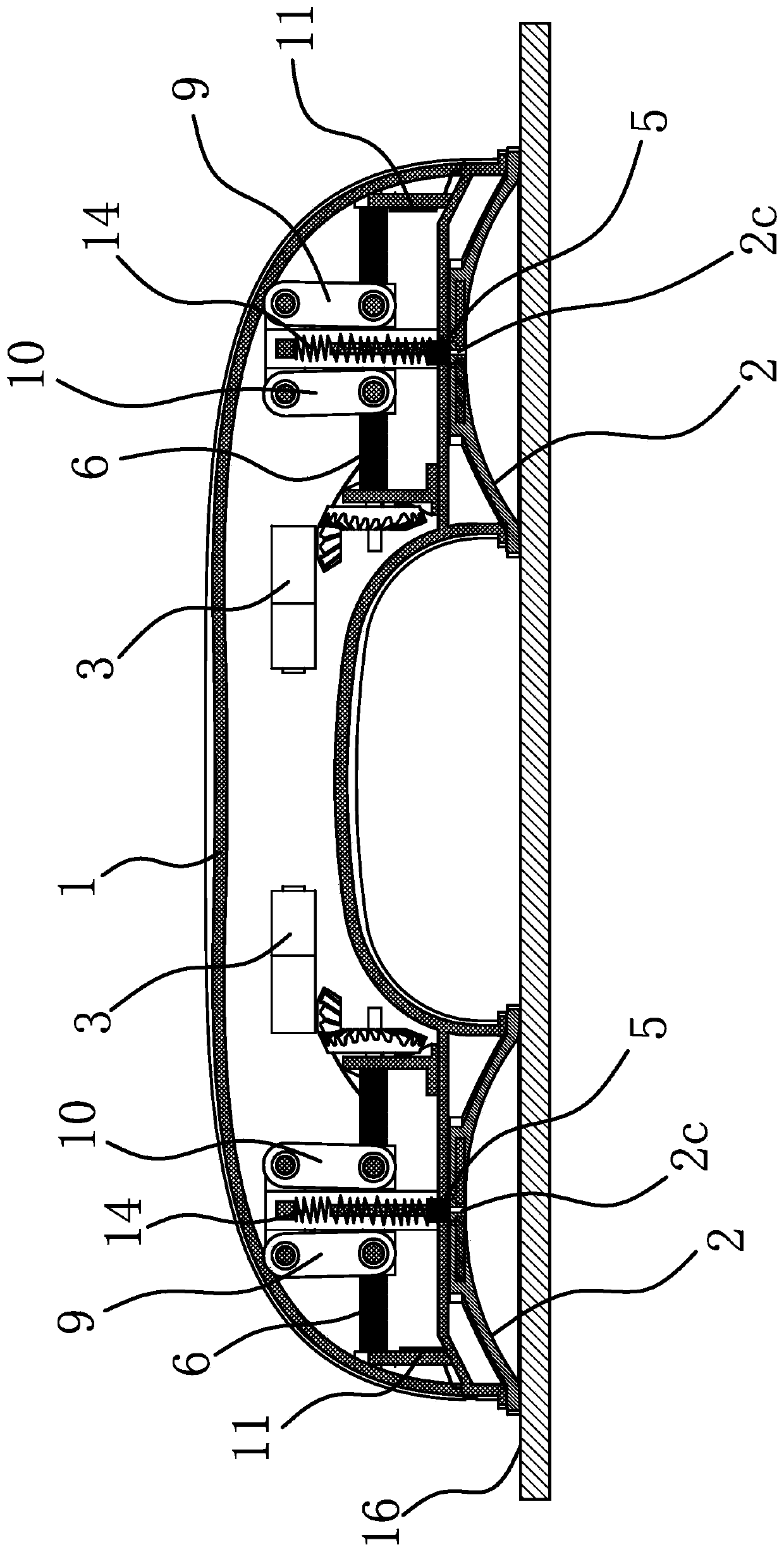

[0030] Such as figure 1 As shown, the automatic handrail includes a U-shaped handle-shaped housing 1, a power supply unit 15, a drive motor 3 and a trigger 4. There is a cavity inside the housing 1, and the drive motor 3 and the power supply unit 15 are fixed in the cavity. The component 4 is connected to the casing 1, and both ends of the casing 1 are provided with circular connecting ports 1a, and the two connecting ports 1a are provided with suction cups 2 and part of the suction cups 2 protrude from the connecting port 1a.

[0031]Wherein, the drive motor 3 is connected to the sucker 2 through the transmission mechanism connected in the casing 1, and the drive motor 3 can drive the sucker 2 to move into the connection port 1a after the trigger 4 is triggered, and make the end faces of the two ends of the casing 1 tighten respectively. Press on the corresponding suction cup 2. In this embodiment, the trigger 4 includes a button; the drive motor 3 is connected to the contro...

Embodiment 2

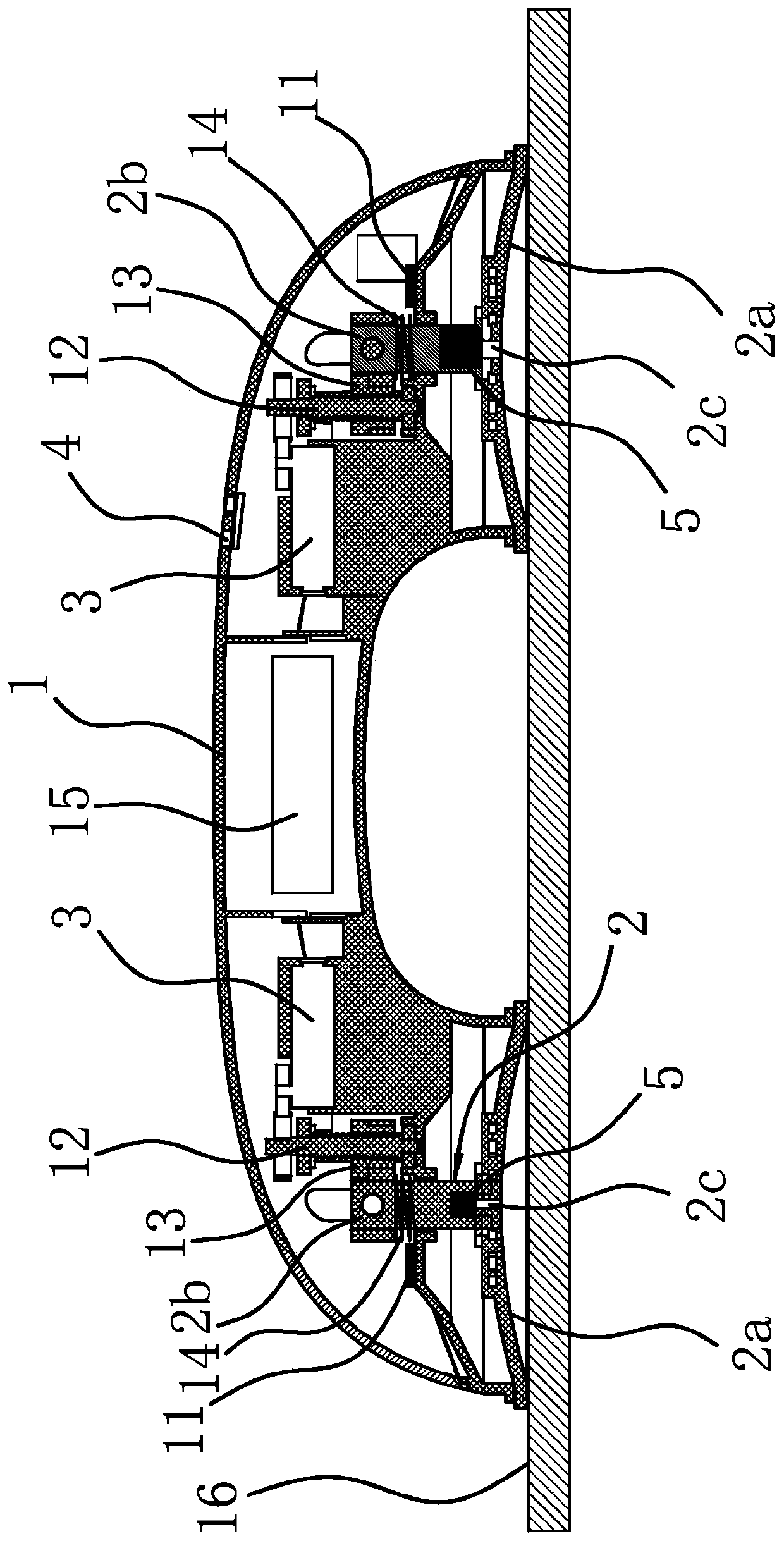

[0040] The solution of this embodiment is substantially the same as that of Embodiment 1, except that the transmission mechanism includes a screw rod 2 12 rotatably connected in the housing 1 and a nut 3 13 threaded outside the screw rod 12, and the setting of the screw rod 2 12 The direction is consistent with the moving direction of the sucker 2, the driving motor 3 can drive the screw rod 2 12 to rotate circumferentially, and the nut 3 13 is fixed with the rod portion 2b of the sucker 2. When the driving motor 3 works, the gear set drives the screw rod 2 12 to rotate circumferentially. Because the nut 3 13 is fixed to the suction cup 2, the nut 3 13 does not rotate circumferentially, but moves along the axial direction of the screw rod 2 12, and then Drive suction cup 2 to move along the axial direction of screw rod 2 12. The trigger 4 can also include a position sensor fixed on the housing 1, which can be used to detect whether the user's hand is blocked, and can also be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com