Construction method of backfilling base of railway crossing giant karst cave

A construction method and technology of karst caves, which are applied in the direction of filling, earth square drilling, mining equipment, etc., can solve problems such as inability to ensure the compactness of backfill, inability to effectively control later settlement, poor stability of cave walls, etc., and achieve good economic benefits and Social benefits, solving the problem of spoilage, and improving the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] like Figure 1-8 As shown, a kind of construction method of the basement backfilling of a railway passing through a giant karst cave according to the present invention comprises the following steps:

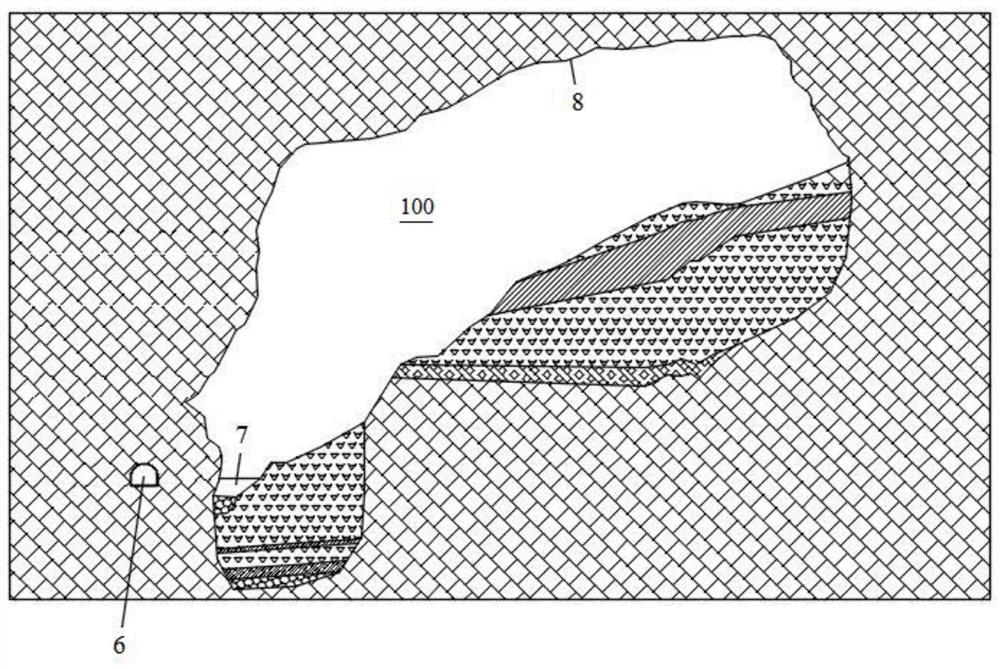

[0040] ① if figure 1 and Figure 8 As shown, at the cave hall 100 slope foot along the underground river 7 water flow direction apart from its right cave wall 50m distance, set up detour drainage tunnel 6, divert the underground river 7 described in the karst cave hall 100 range, divert the underground river 7 Water diversion from upstream to downstream;

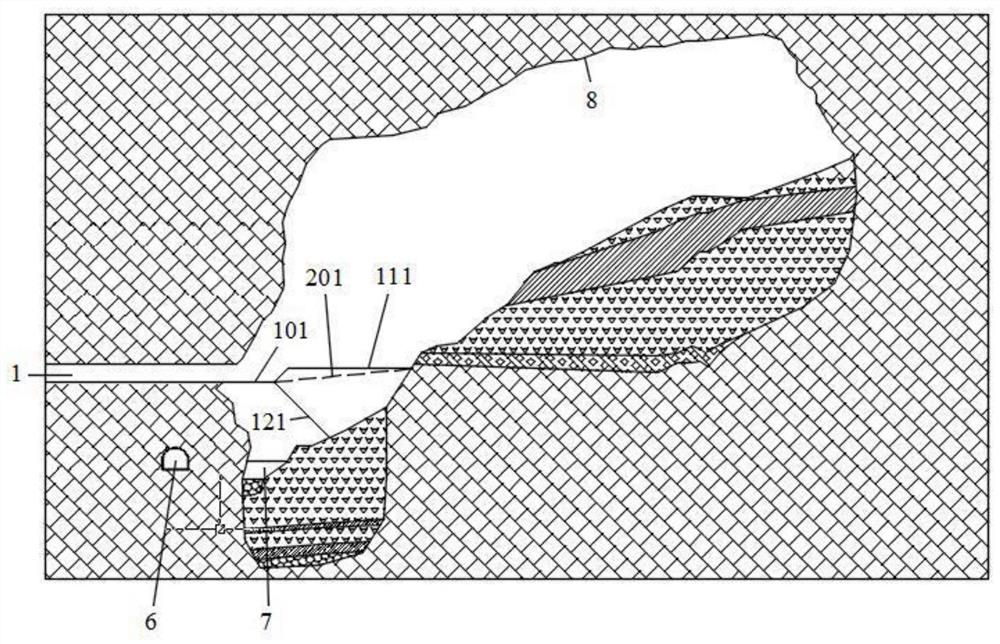

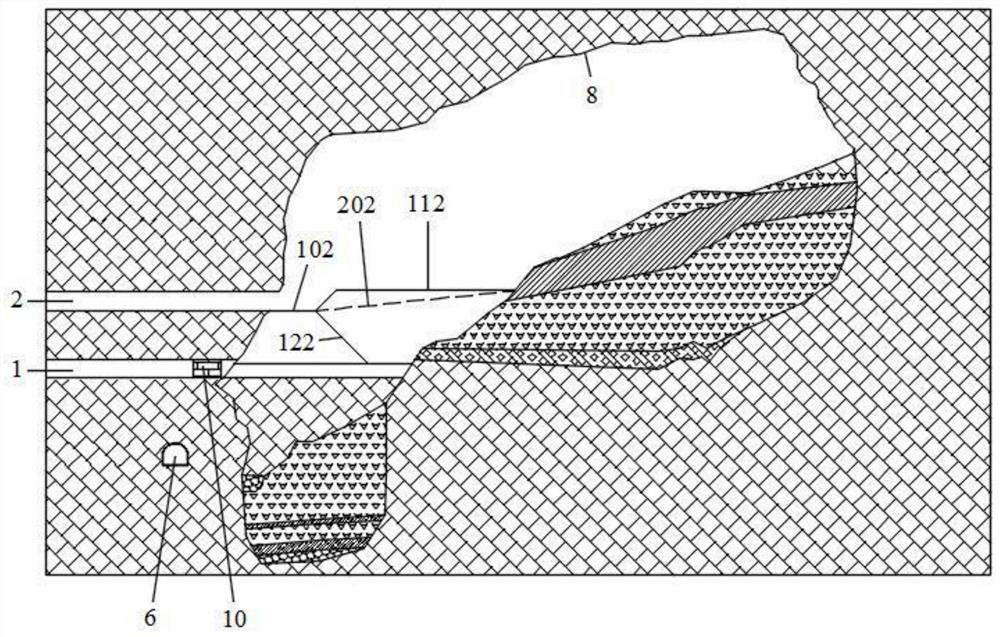

[0041] ② if figure 2As shown, the first channel 1 is constructed on the side of the slope foot of the cave hall 100, and the first channel 1 is connected to the cave wall. At the intersection of the first channel 1 and the cave hall 100, a 10m backfilling is performed by throwing and filling blocks. The first construction platform 101 of ×10m, the first construction platform 101 is flush with the bottom of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com