Anti-stain draught fan

A fan and anti-fouling technology, applied in the direction of electromechanical devices, mechanical equipment, control mechanical energy, etc., can solve the problems of unbalanced operation of fan blades, increased vibration, corrosion of fans, etc., and achieve the effect of saving later maintenance costs and ensuring normal working functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

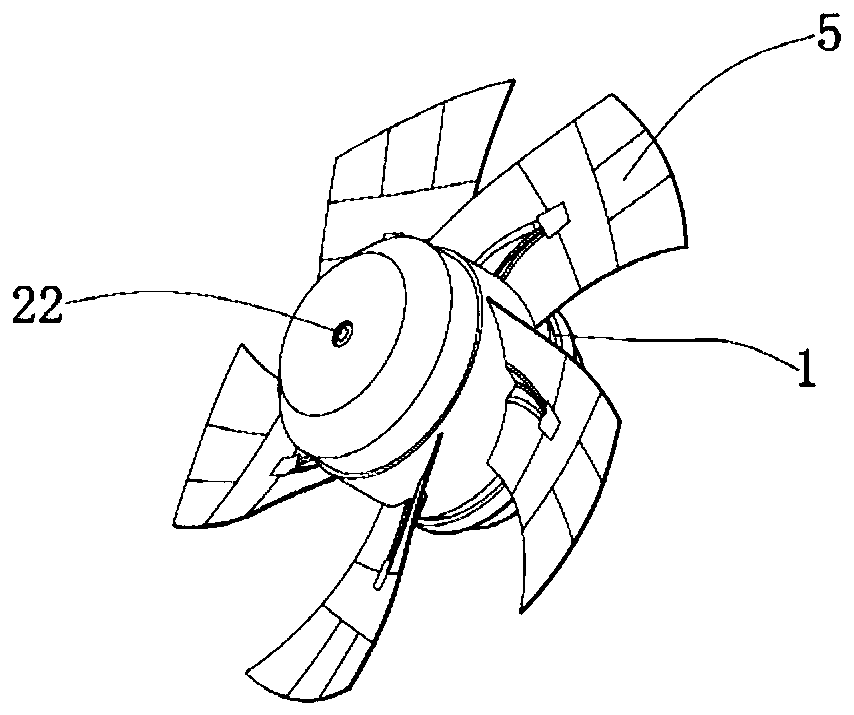

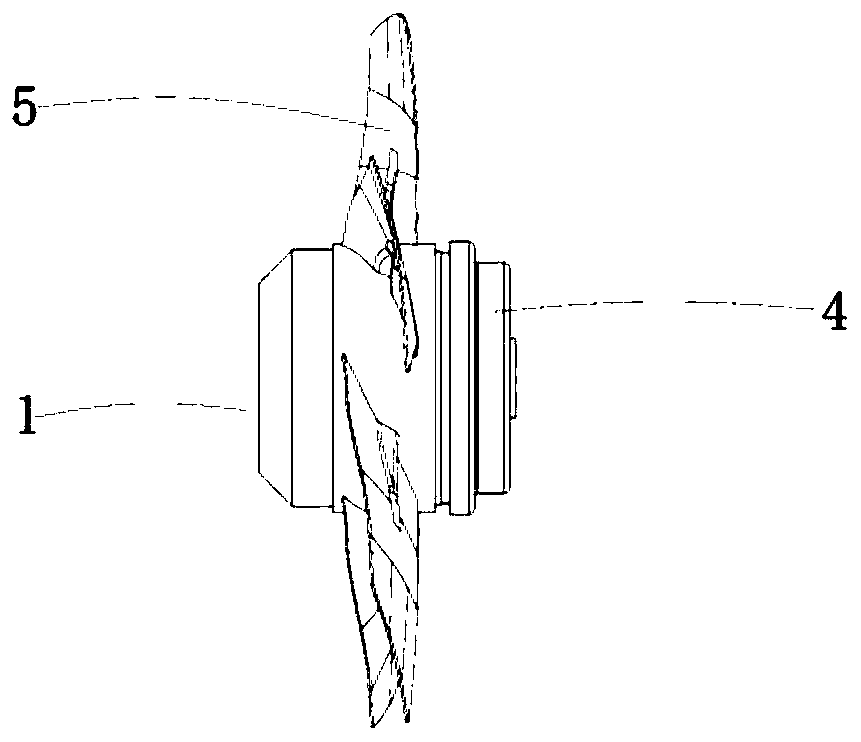

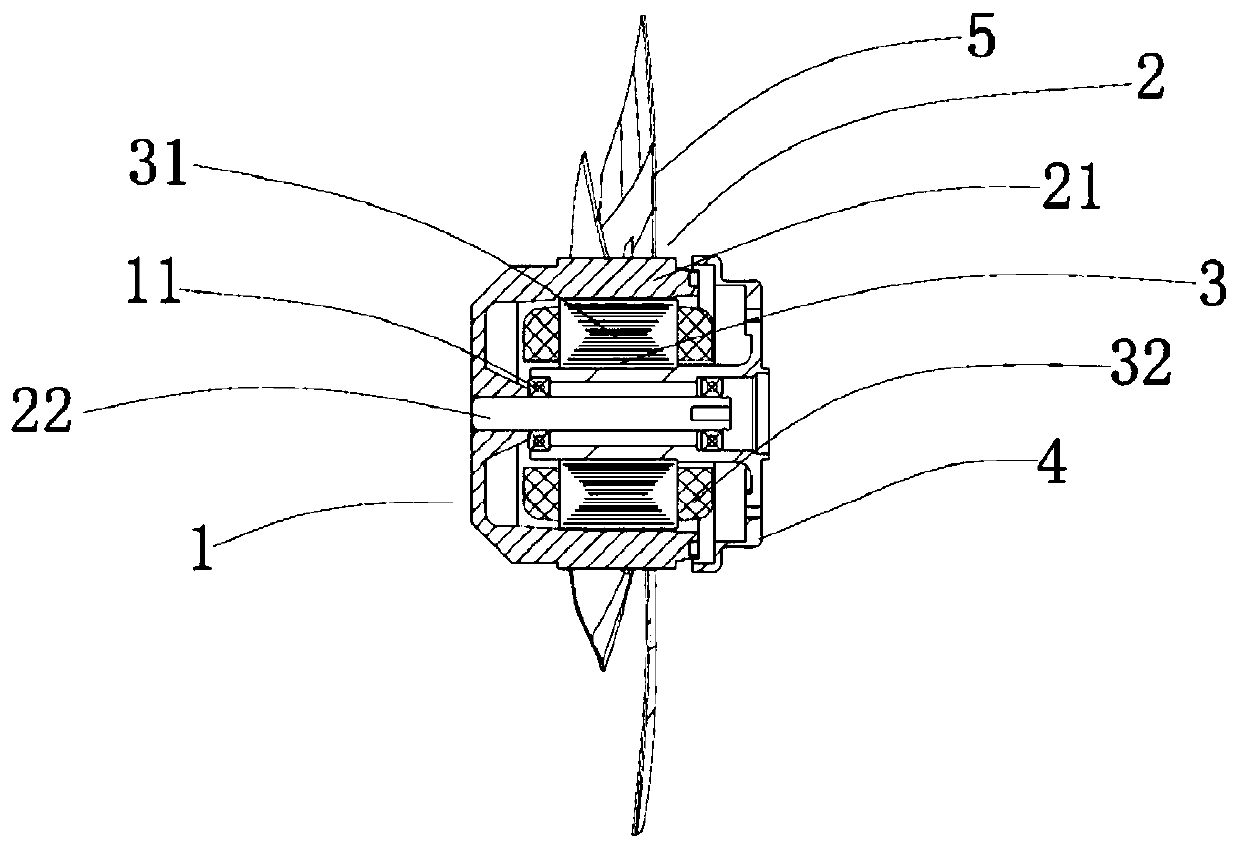

[0015] Such as Figure 1 to Figure 3 As shown, the anti-fouling blower in this embodiment includes a frame 1 , a stator assembly 3 and a rotor assembly 2 arranged in the frame 1 , and fan blades 5 uniformly installed on the frame 1 . In order to stabilize the internal components of the machine base 1 , an end cover 4 with a sheet structure is installed at one end of the machine base 1 .

[0016] Wherein, the base 1 is configured as a cylindrical structure with a hollow cavity inside, and a bearing 11 is installed in the middle of the base 1 and a corresponding rotor assembly 2 and a stator assembly 3 are installed. The rotor assembly 2 includes a rotor core 21 and a rotating shaft 22 . Specifically, the rotor core 21 is made of silicon steel and is arranged on the inner wall of the frame 1 . The rotating shaft 22 is installed on the bearing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap