Shell and tube type heater

A heater and shell-and-tube technology, which is applied in the field of shell-and-tube heaters, can solve the problems of complex heating tubes and tube sheets, high material grade requirements, and high cost, and achieve weight reduction, reduced pressure resistance requirements, and high cost of materials. The effect of level reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

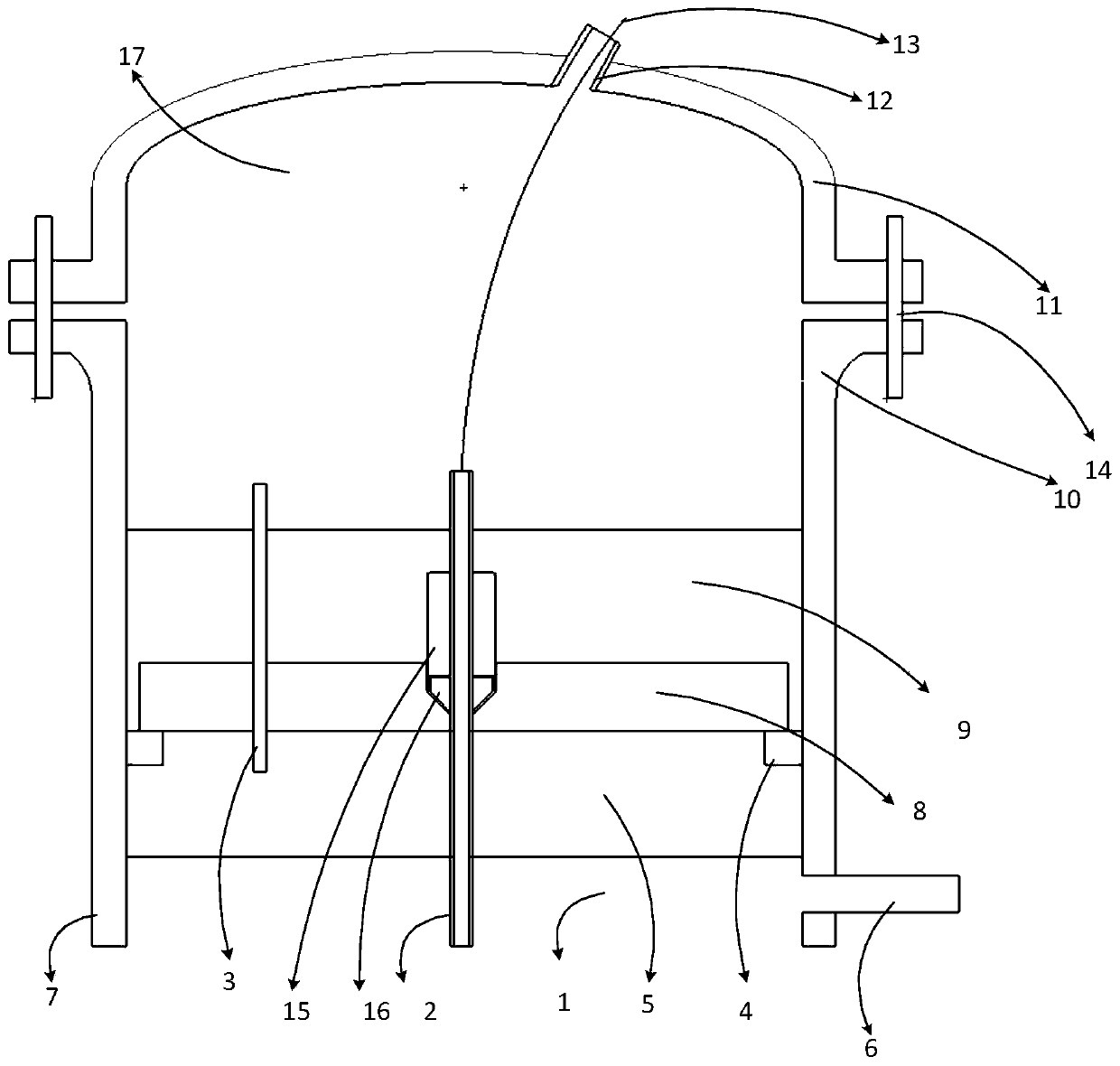

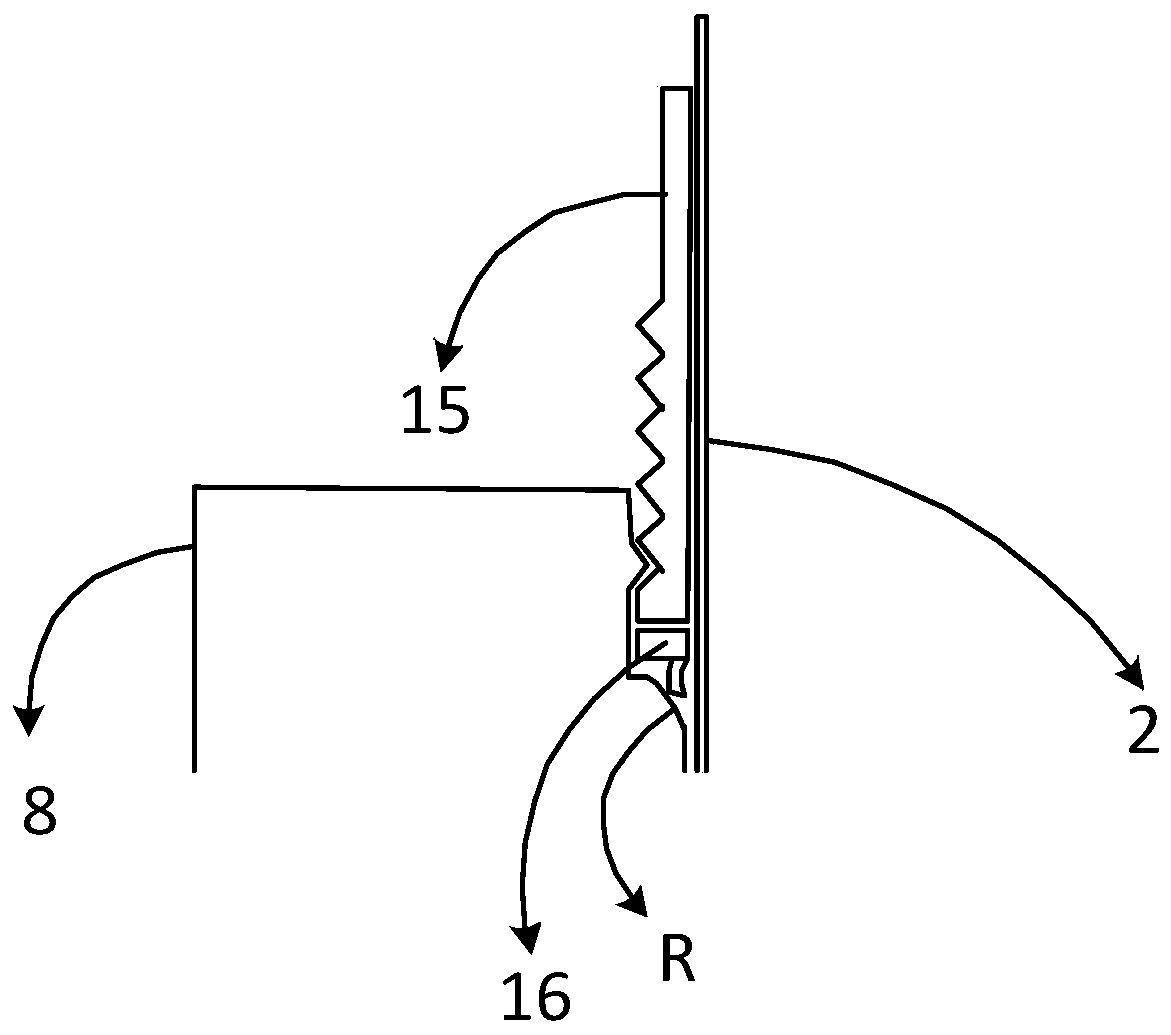

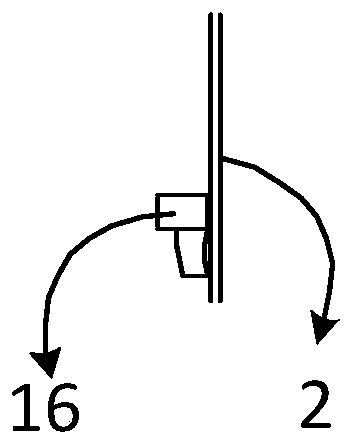

[0036] Such as figure 1 As shown, the shell-and-tube electric heater of the present invention includes an upper head 11 , a heating container 7 , a tube plate 8 , an electric heating tube 2 and a ventilation tube 3 .

[0037] The upper head 11 and the heating container 7 are connected by bolts 14 and flanges 10; the tube sheet 8 and the electric heating tube 2 are connected by ferrules 16 and screw sleeves 15 ( figure 2 and image 3 Shown); Boss 4 (a ring of bosses are set around the inner wall of heating vessel 7) is used to support tube sheet 8; the heat insulation layer 9 of aluminum silicate fiber is laid on the tube sheet 8, and the first heat insulation layer 9 above A space 17 is used to accommodate inert gas; the cable 13 of the electric heating tube 2 is connected to the power cabinet through the flange hole 12 on the upper head 11; the heated liquid 1 in the heating container 7 flows into the circuit through the outlet pipe 6; The heating liquid 1 and the lower su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com