Thermal superconduction heat dissipation plate, thermal superconduction radiator and 5G base station equipment

A technology for base station equipment and radiator substrates, which is applied in the fields of thermal superconducting radiators, radiators, and 5G base station equipment. It can solve problems such as uneven heat dissipation, low heat dissipation efficiency, and bulkiness, and achieve high integration and temperature uniformity. , prolong the service life of the equipment and improve the performance of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

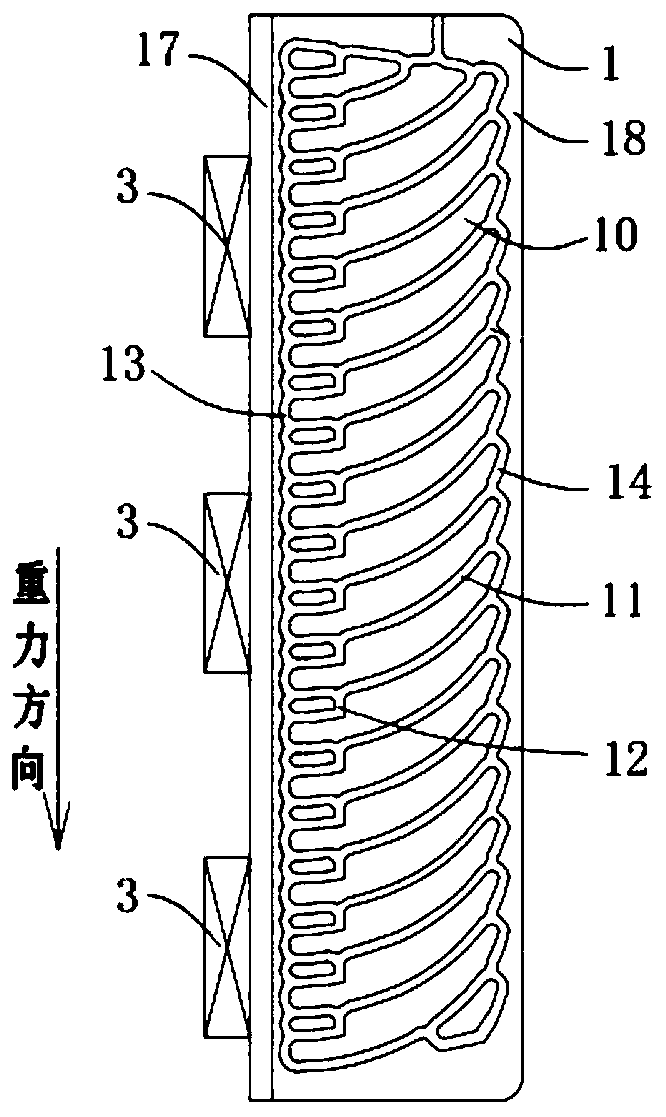

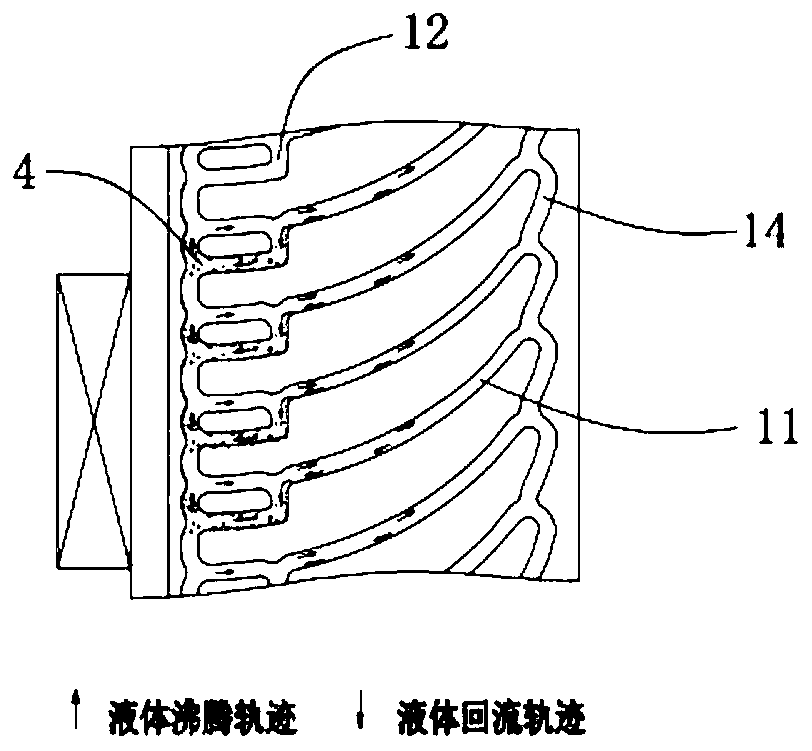

[0041] Such as Figure 1 to Figure 2 As shown, the present invention provides a thermal superconducting heat sink 1 in which a heat dissipation main pipe 11, a liquid drop pipe 12, a heat receiving side communication pipe 13 and a condensing side communication pipe 14 are distributed. The heat-receiving-side communication pipeline 13 is located on the side of the thermal superconducting heat sink 1 adjacent to the heating device 3, and the condensing-side pipeline is located on the opposite side of the heat-receiving-side communication pipeline 13; The heat dissipation main pipe 11 is connected between the heat receiving side communication pipe 13 and the condensing side communication pipe 14, and the liquid drop pipeline 12 is located under the heat dissipation main pipe 11 in a one-to-one correspondence with one end It is connected with the corresponding heat dissipation main pipe 11, and the other end is connected with the heat-receiving side communication pipe 13; the heat ...

Embodiment 2

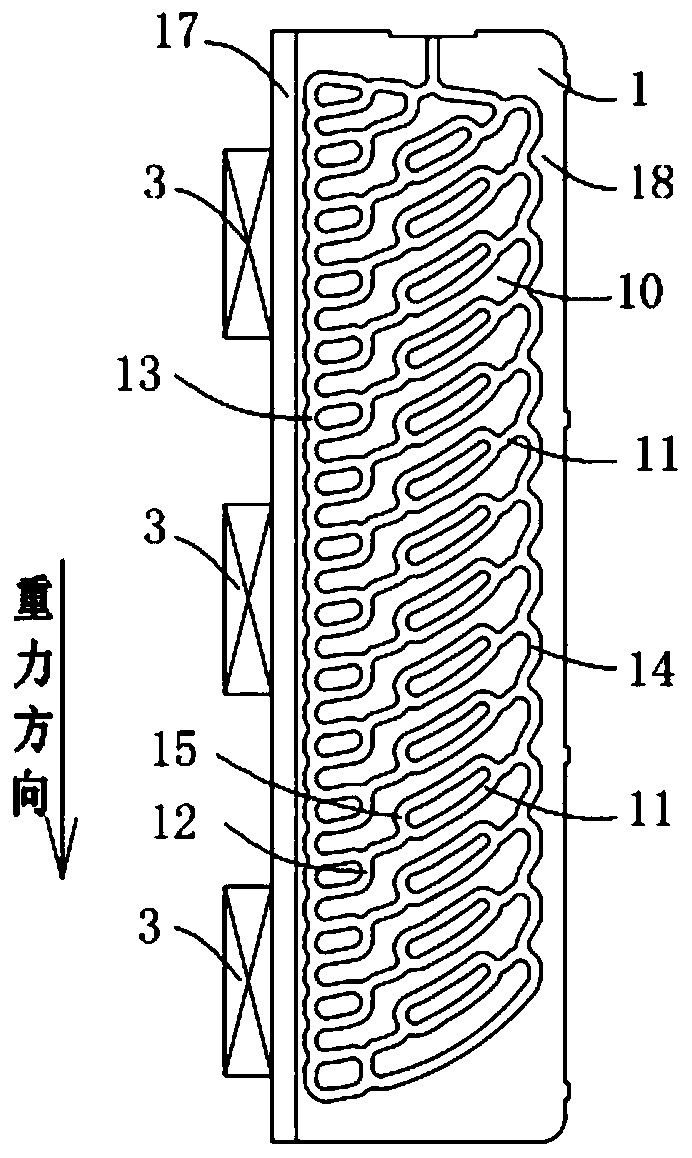

[0050] Such as image 3 with Figure 4 As shown, this embodiment provides a thermal superconducting heat sink 1 of another structure. The difference between the thermal superconducting heat sink 1 of this embodiment and the first embodiment is that the thermal superconducting heat sink 1 of this embodiment further includes a plurality of steam rising pipes 15 which are located at all locations one by one. Above the heat dissipation main pipe 11, and both ends are connected with the heat dissipation main pipe 11, and the steam rising pipe 15 and the liquid falling pipe 12 are usually spaced apart, and the projections of the two in the longitudinal direction do not overlap . The steam rising pipe 15 may include a straight section and a bent section at both ends of the straight section, so the steam rising pipe 15 and the heat dissipation main pipe 11 enclose a plurality of similar rectangular islands without pipes. Area 10, please refer to image 3 . The thermal superconducting...

Embodiment 3

[0052] Such as Figure 5 As shown, this embodiment provides a thermal superconducting heat sink 1 of another structure. The difference between the thermal superconducting heat sink 1 of this embodiment and the second embodiment is that both ends of the steam rising pipe 15 of the thermal superconducting heat sink 1 of the second embodiment are connected to the heat dissipation main pipe 11, and this embodiment In the example, although there are also a plurality of steam rising pipes 15, the steam rising pipes 15 are also located above the heat dissipation main pipe 11 in a one-to-one correspondence, but one end of the steam rising pipe 15 of this embodiment is connected to the heat sink The main pipe 11 is connected, and the other end is connected with the condensing side communication pipe 14, and the steam rising pipe 15 and the liquid falling pipe 12 are usually separated from each other, and their longitudinal projections do not overlap. The steam rising pipe 15 may include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com