Device for controlling detonating cord multi-point explosion propagation synchronization

A detonating cord and synchronization technology, which is applied in the direction of blasting barrels, weapon accessories, offensive equipment, etc., can solve the problems of poor synchronization of multi-point output of the detonation transmission network and low detonation efficiency, so as to eliminate the delay of detonation time and improve the efficiency of detonation. Detonation efficiency, impact avoidance and detonation breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

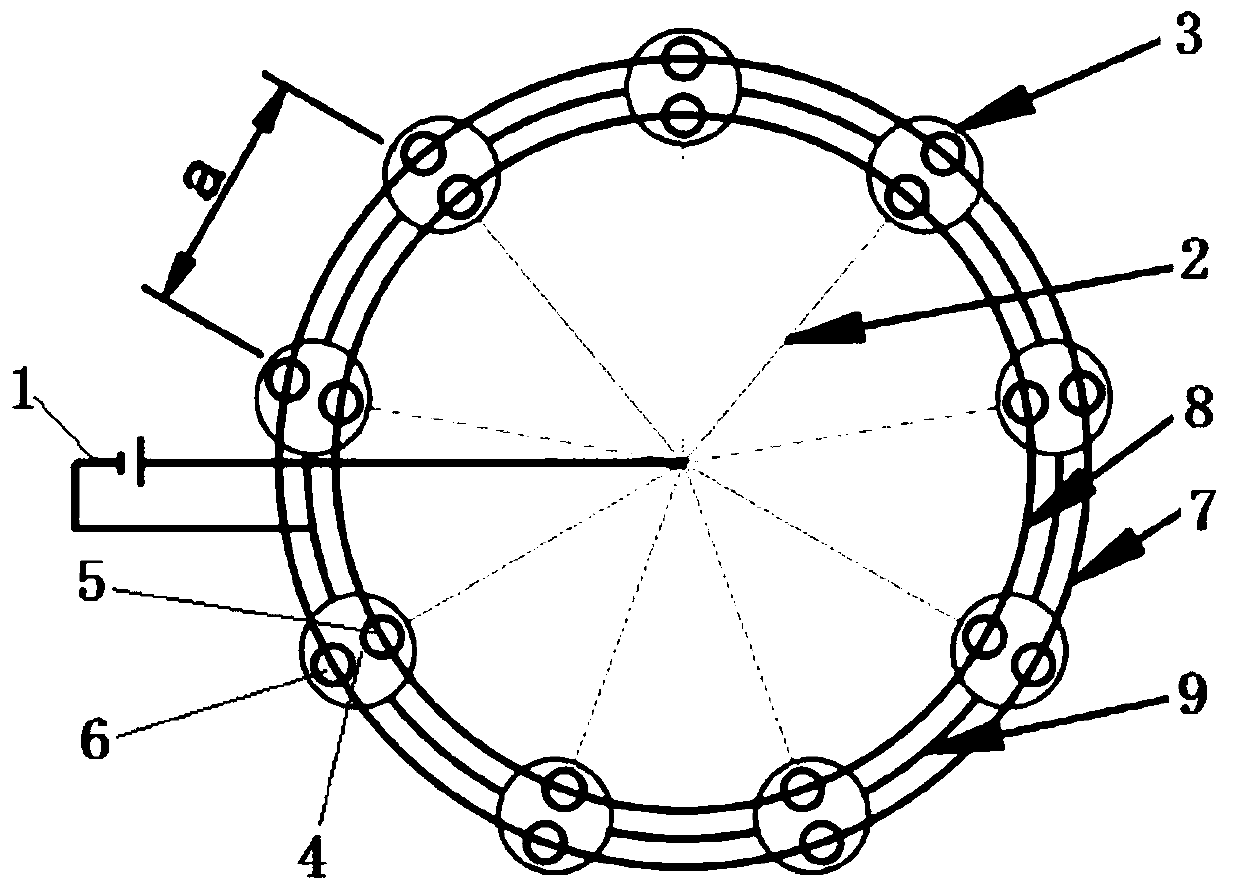

[0019] see figure 1 , a device for controlling the synchronization of multi-point transmission of detonating cords, comprising a power supply 1, a detonating cord 2, nine copper-clad laminates 3 and nine booster charges 4; the nine booster charges 4 are arranged in a ring at equal intervals, each Each booster charge 4 is placed on the copper clad laminate 3, and an inner electrode plug 5 and an outer electrode plug 6 are arranged on the copper clad laminate 3. The inner electrode plug 5 and the outer electrode plug 6 are respectively located at both ends of the booster charge 4, each The inner electrode plugs 5 and the outer electrode plugs 6 on the copper clad laminate 3 are arranged symmetrically, and the plurality of outer electrode plugs 6 are evenly distributed on the largest diameter circle 7 at equal intervals, and the plurality of inner electrode plugs 5 are evenly distributed on the smallest diameter circle 8 at equal intervals. , the booster charges 4 are evenly dist...

Embodiment 2

[0024] The difference from Example 1 is that in this example, the printing thickness of the copper clad laminate is selected to be 50 μm, and the detonation voltage is 24 V. The layout is performed as shown in the figure. After the layout is completed, the synchronous trigger is turned on for synchronous detonation.

[0025] Comparison of the two embodiments: in embodiment 2, due to the large printing thickness of the metal plate, the small resistivity, the detonation is fast, and the voltage of embodiment 2 is higher than that of embodiment 1, so the detonation is faster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com