Device and method for surface inspection of a wedge for fixing a bar of a generator

A technology for inspection devices and generators, applied in the direction of electromechanical devices, manufacturing motor generators, using/manufacturing slot locking devices, etc., can solve problems such as long maintenance time, and achieve the effects of easy transportation, reduced size, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

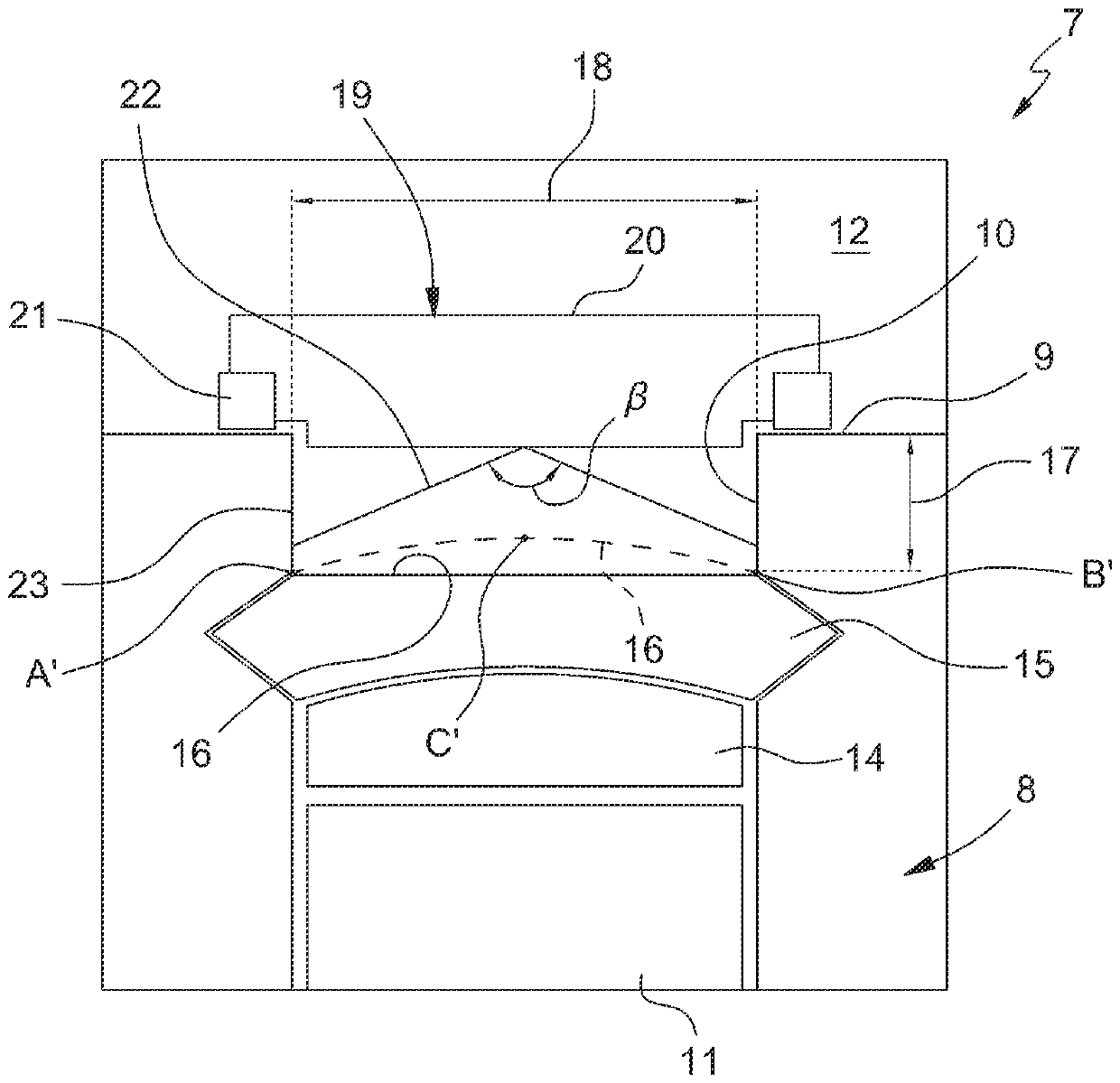

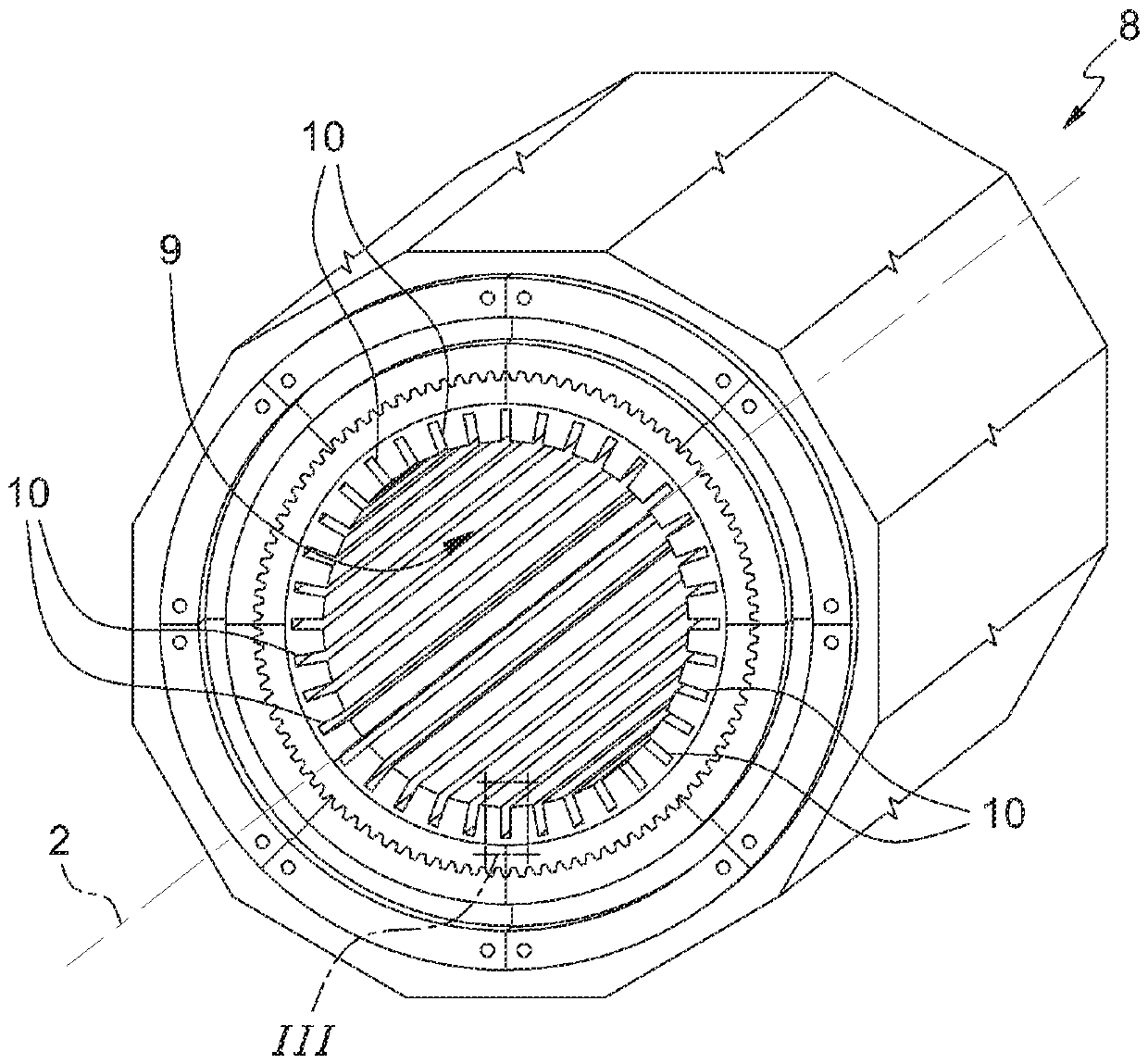

[0052] Hereinafter, in cooperation with the accompanying drawings, the technical contents and details of the present invention are described according to preferred embodiments, which are not intended to limit the scope of implementation of the present invention. The claimed claims of the present invention cover all equivalent changes and modifications made in accordance with the appended claims.

[0053] The present invention will now be described in detail with reference to the accompanying drawings.

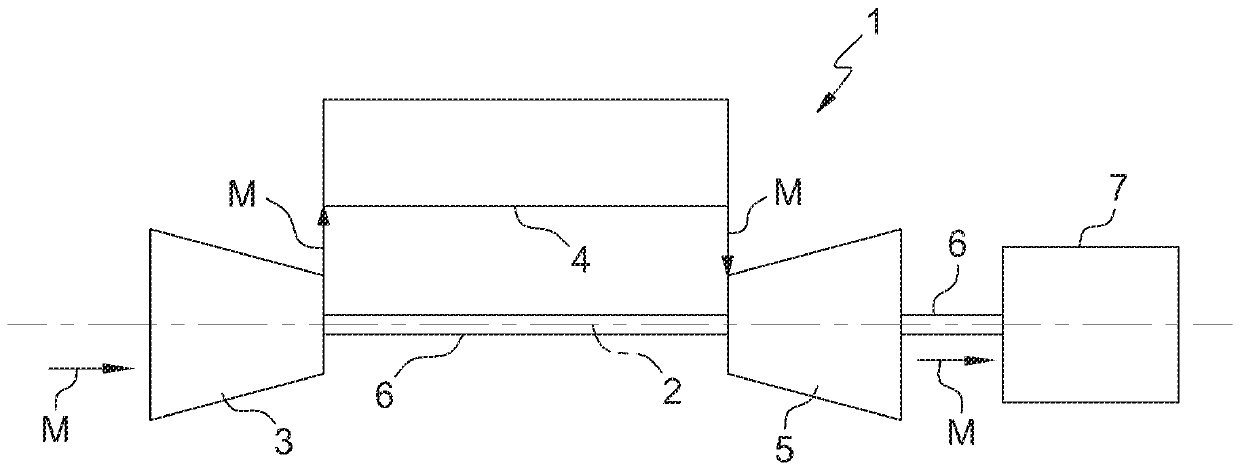

[0054] refer to figure 1 , figure 1 is a schematic diagram of a gas turbine assembly (hereinafter simply referred to as a gas turbine) for a power plant. Indeed, the field of gas turbine generators is a non-limiting example of application of the invention. figure 1 A gas turbine 1 is shown having a rotor 6 defining an axis 2 and comprising, in series along a main flow M:

[0055] - compressor unit 3,

[0056] - a burner unit 4 in which compressed air is mixed with at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com