Automobile stamping part testing fixture

A technology for automotive stamping parts and inspection tools, which is applied in the direction of manufacturing tools, workpiece clamping devices, measuring devices, etc., can solve the problems of not being able to apply stamping parts of different specifications, and achieve the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

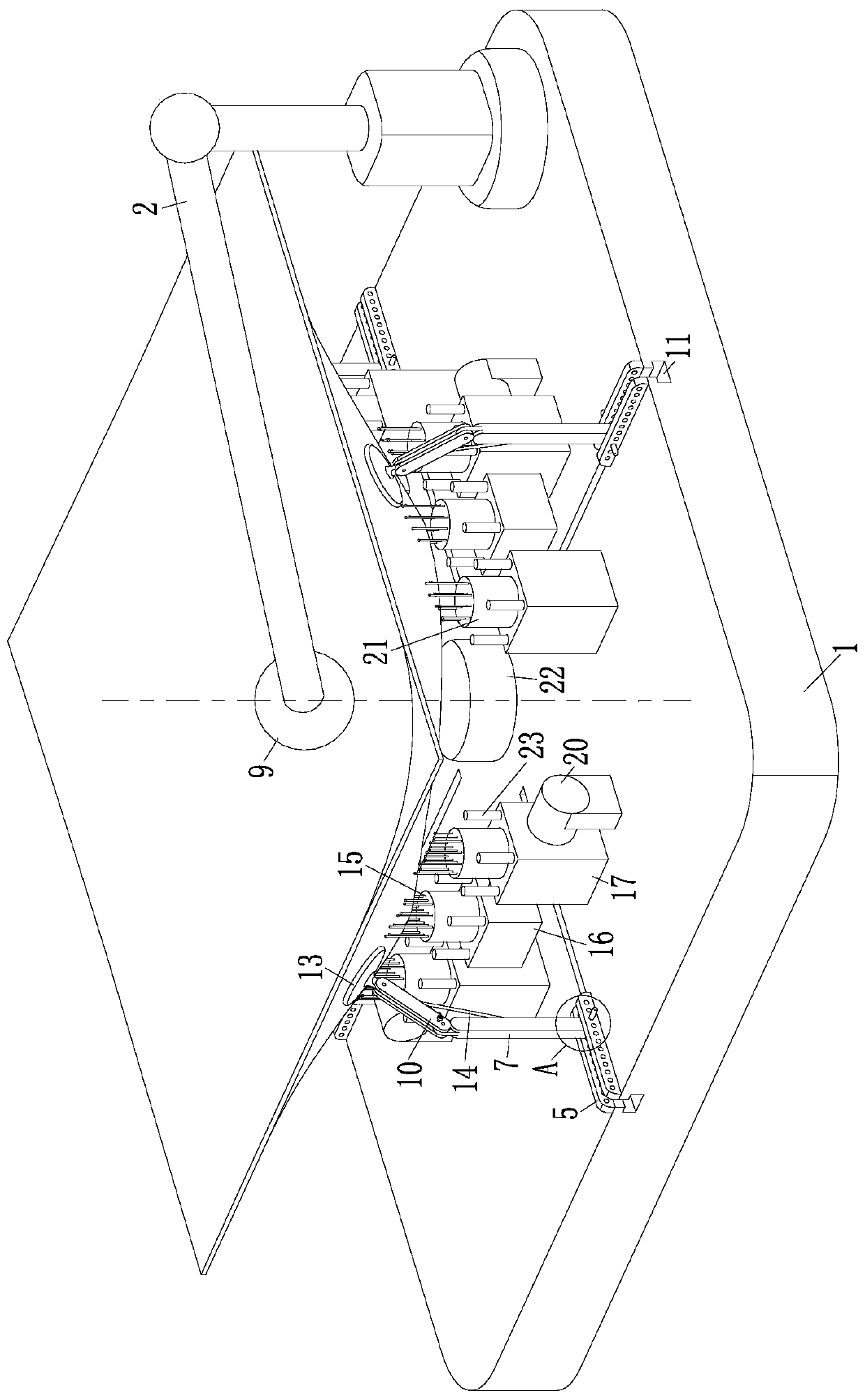

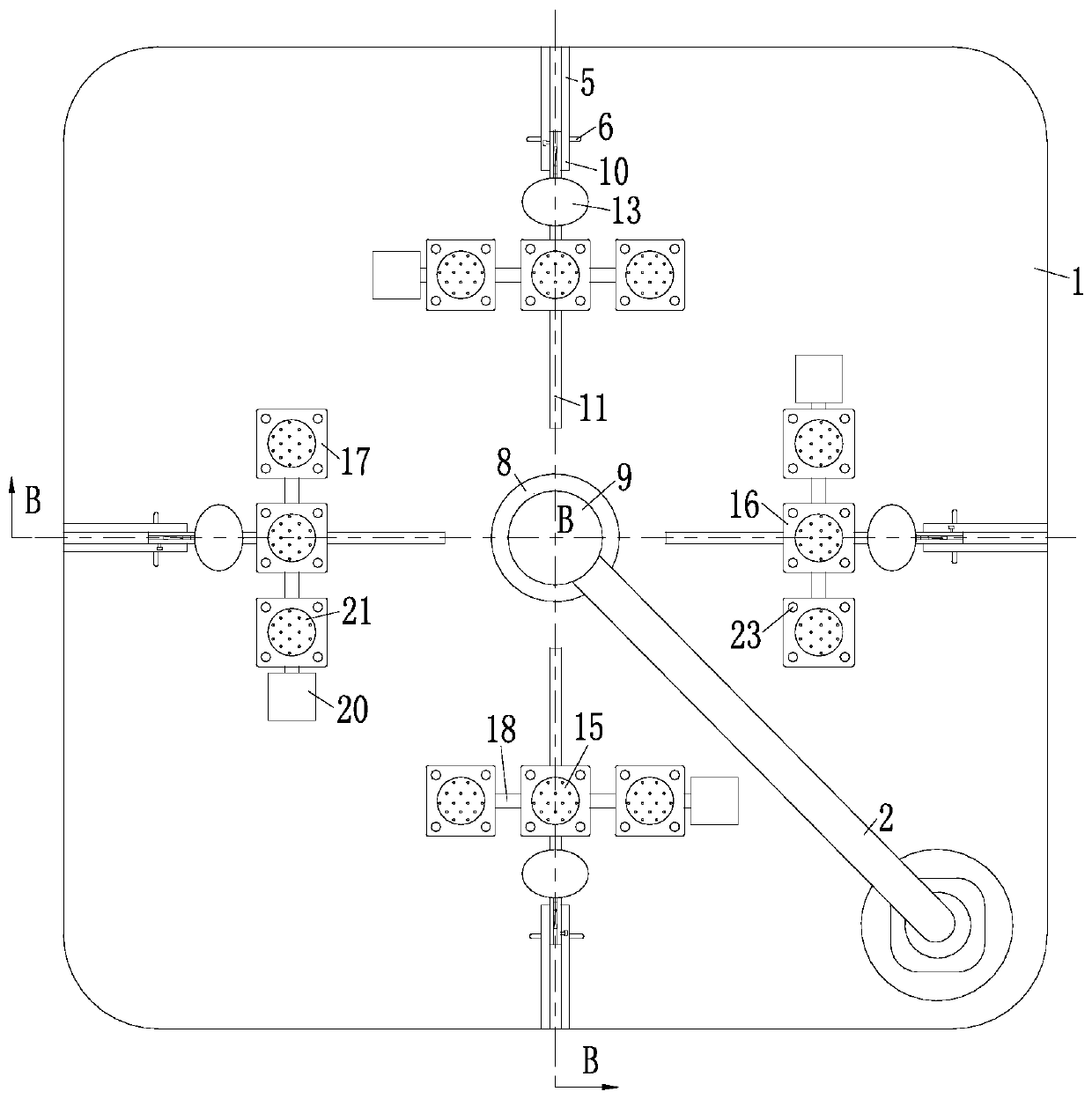

Method used

Image

Examples

Embodiment approach

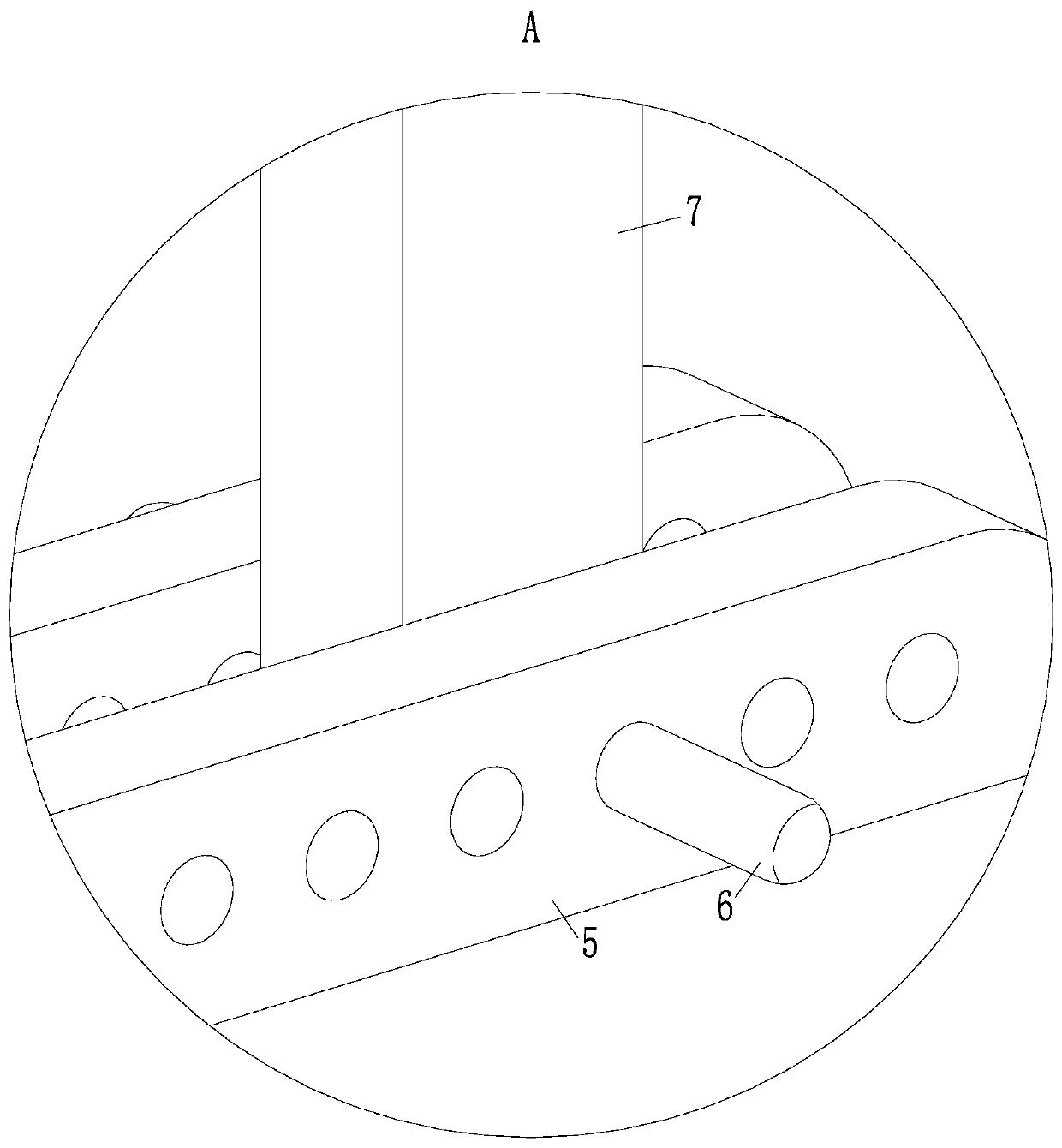

[0029] As an embodiment of the present invention, the swing range of the hinge arm 10 around the support arm 7 is 160 degrees; the middle part of the hinge arm 10 is fixedly connected with the middle part of the support arm 7 with an elastic rope 14; After the stamping part is detected, the lifting unit 3 is started to raise the stamping part to be taken out. Because the rubber suction cup 13 has an adsorption force on the outer wall of the stamping part, the stamping part will drive the rubber suction cup 13 to move upward. The rubber suction cup 13 and the hinge arm 10 The connection mode is hinged, so it will drive the hinge arm 10 to move upward. Because the hinge arm 10 is fixed by the friction force generated between the hexagon socket head screw 12 and the support arm 7, and its friction force is limited, it will drive the hinge arm 10 to move upward. Angle offset, in the next measurement, the stamping part cannot be fixed, which affects the detection of the stamping par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com