High-pressure and high-temperature simulation experiment system for fidelity coring device

A technology for simulation experiments and corers, applied in sampling devices and other directions, can solve problems such as damage to pressure-holding experimental chambers, lack of simulation, and unreliable experimental results, to prevent damage, improve integrity, and improve accuracy and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

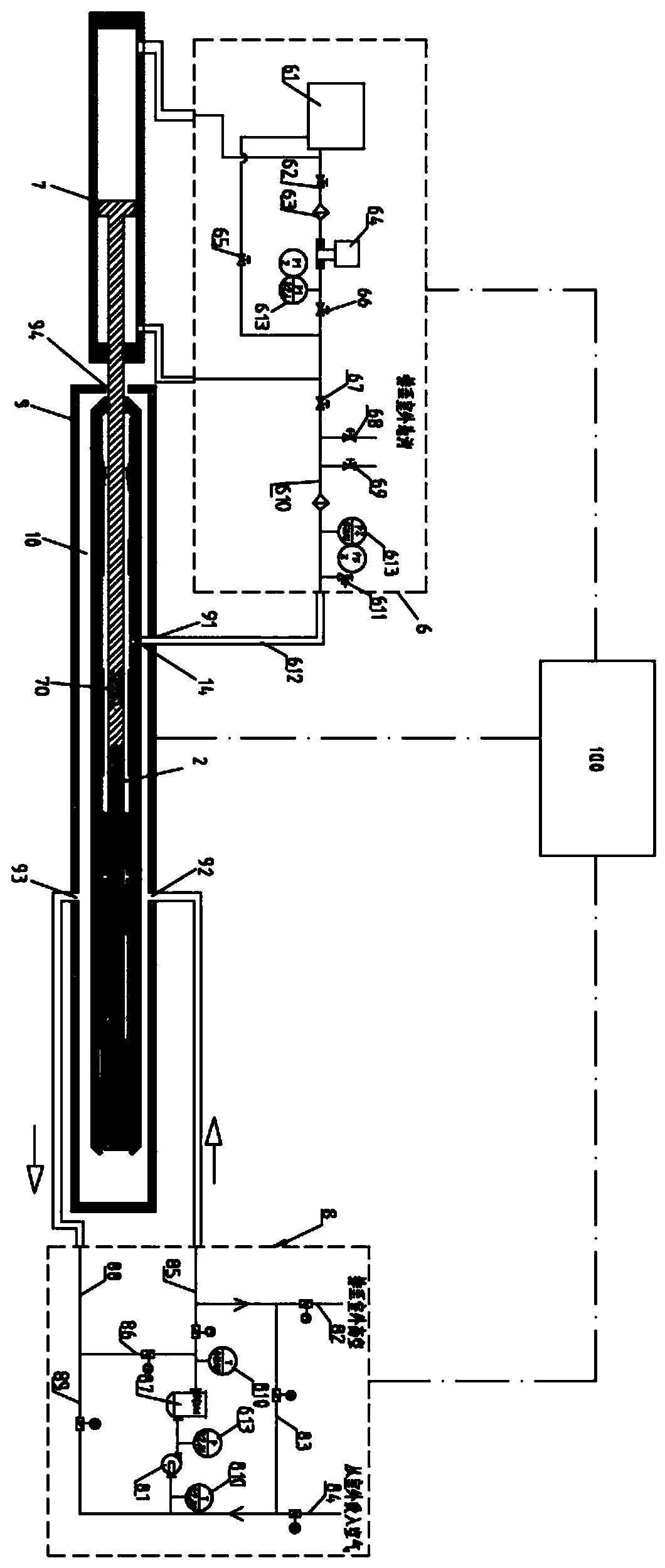

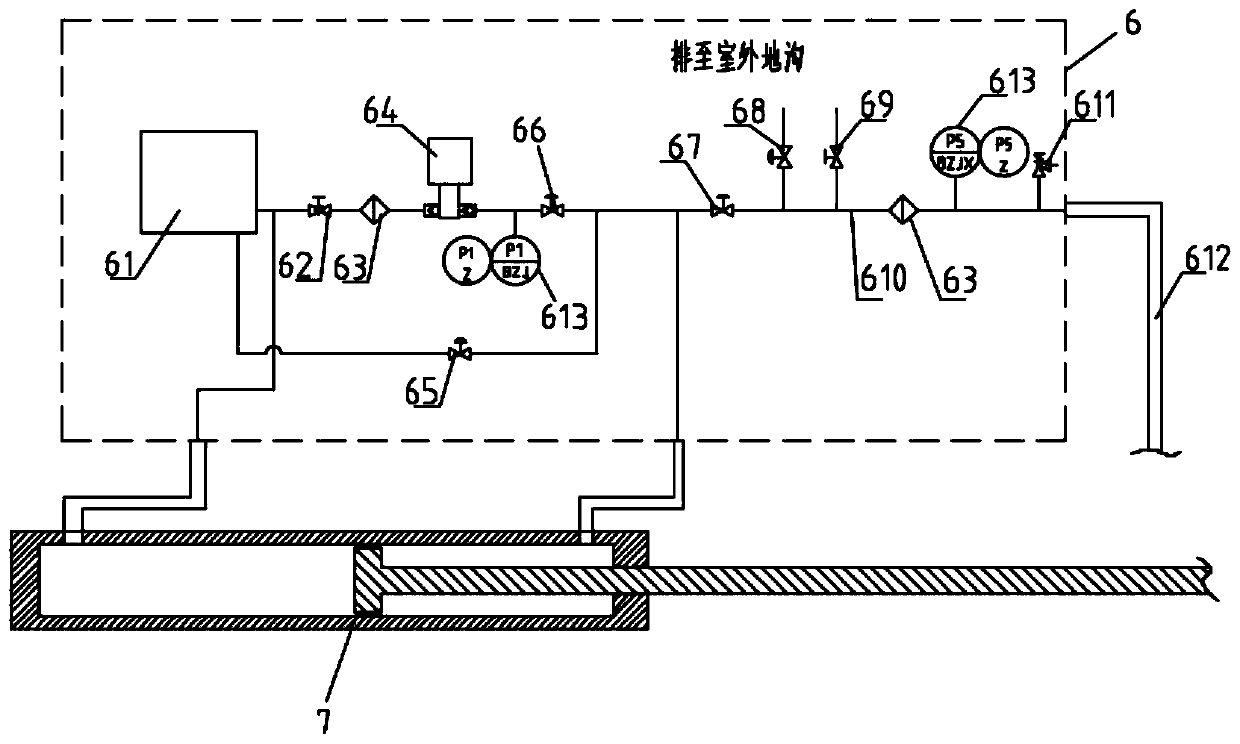

[0038] Such as figure 1 , 2 , 3, the fidelity coring device high-pressure high-temperature simulation experiment system disclosed in this embodiment includes a pressure supply unit 6 , a heat source supply unit 8 , a high-temperature and high-pressure chamber, a data acquisition unit and a control unit 100 . The high temperature and high pressure chamber includes a thermostat 9 and a pressure experiment chamber 10 placed in the thermostat 9. The thermostat 9 is provided with a medium inlet 92, a medium outlet 93 and a first reserved hole 91 for the test pipeline to pass through. The positions of the medium inlet 92 and the medium outlet 93 are set as required. In this embodiment, the medium inlet 92 and the medium outlet 93 are set on opposite sides of the incubator 9 .

[0039] The pressure supply unit 6 is connected to the pressure test chamber 10 through pipelines to adjust the pressure in the pressure chamber 2, so as to realize the simulation of the high-pressure environ...

Embodiment approach 2

[0077] In Embodiment 1, the pressure-holding experimental cabin is connected to the hydraulic pipeline by drilling holes in the cylinder wall, and the drilling of the drilling rig will damage the pressure-holding experimental cabin, thereby making the experimental results unreliable.

[0078] Such as Figure 8 , 9 , 10, the cabin body of the pressure test cabin 10 in the present embodiment comprises the first test piece 11, the second test piece 12 and the intermediate connector 13, the first test piece 11 is the outer cylinder 1 upper end of the pressure-holding test cabin, The second experimental piece 12 is the lower end of the outer cylinder 1 of the pressure-holding experimental cabin, and the intermediate connecting piece 13 is a cylindrical structure; the first experimental piece 11 and the second experimental piece 12 are connected through the intermediate connecting piece 13, and the liquid injection hole 14 is arranged in the middle The cylinder wall of the connecti...

Embodiment approach 3

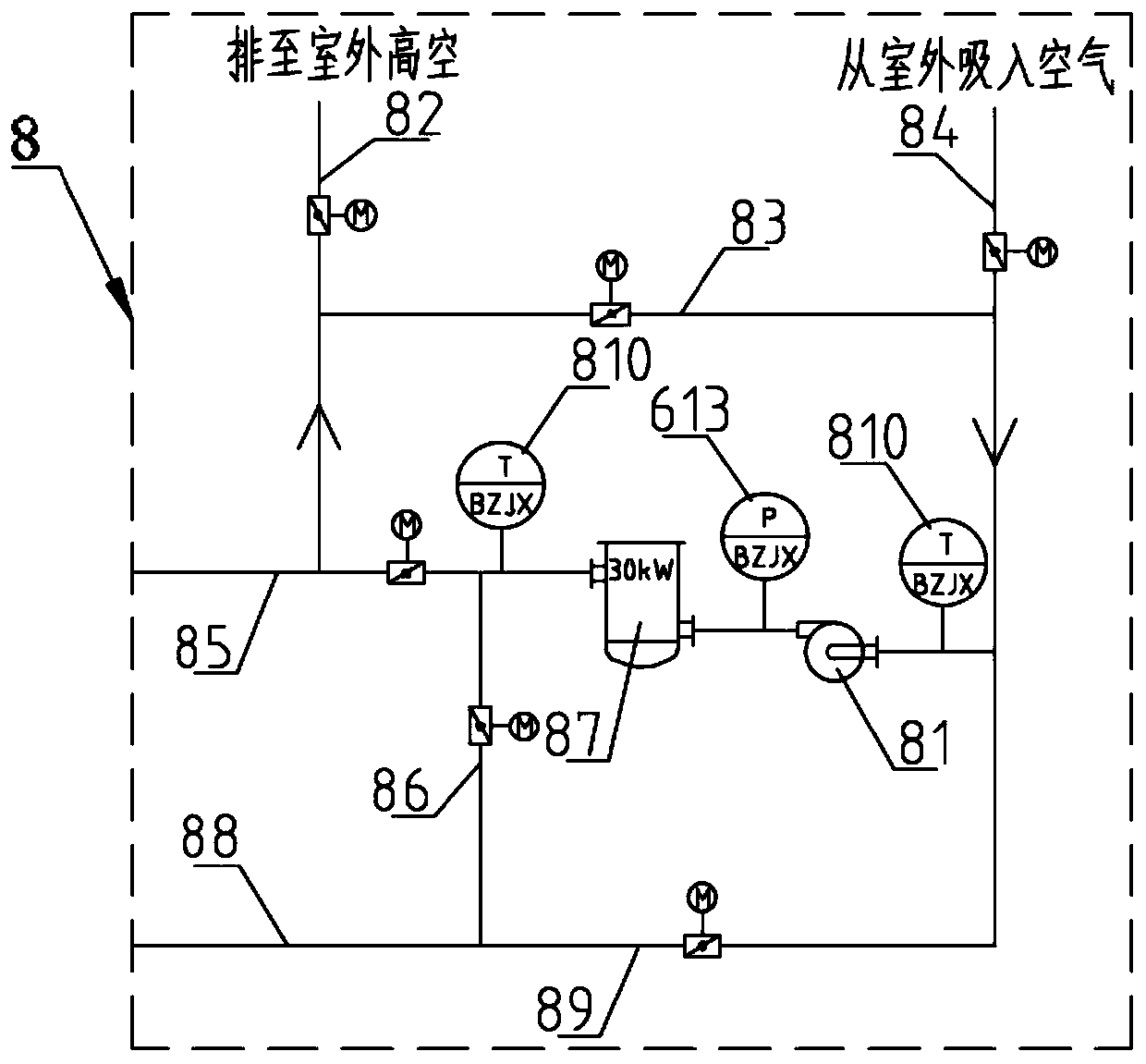

[0084] The difference between this embodiment and the first and second embodiments is that the heat source supply unit 8 is different. Such as Figure 11 As shown, the heat source supply unit 8 in this embodiment includes a liquid supply system and an electric heater 805. The liquid supply system includes an oil tank 801 and a pump 802. The outlet of the oil tank 801 is connected to the inlet of the pump 802, and the outlet of the pump 802 is connected to the electric heater. 805 is connected to the inlet, and the outlet of the electric heater 805 is connected to the medium inlet 92 of the thermostat 9 through the liquid inlet pipeline 803 .

[0085] The medium outlet 93 of the thermostat 9 is connected to one end of the liquid outlet pipeline 804 , and the other end of the liquid outlet pipeline 804 is connected to the oil tank 801 . The connecting pipeline between the pump 802 and the electric heater 805 is provided with a filter, a pressure gauge, a safety valve 611 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com