Method for testing fatigue shear resistance of new and old concrete joint surface

A technology for new and old concrete and new concrete, which is applied in the direction of testing material strength, measuring device, strength characteristics, etc. by applying repetitive force/pulsation force, so as to achieve the effect of convenient and simple production and prolonging fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The new and old concrete interface fatigue shear performance test method of the present invention, the method is specifically as follows:

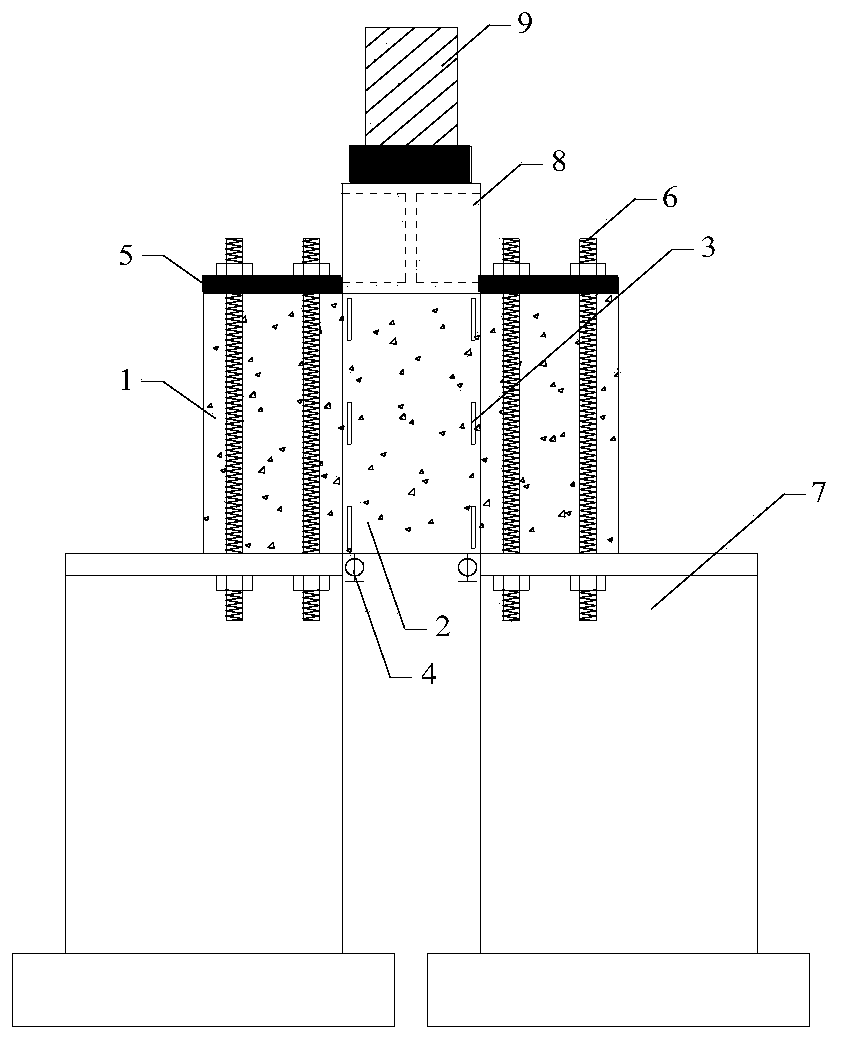

[0049] S1, two prefabricated old concrete test pieces 1 are respectively fixed on two symmetrically placed steel supports 7;

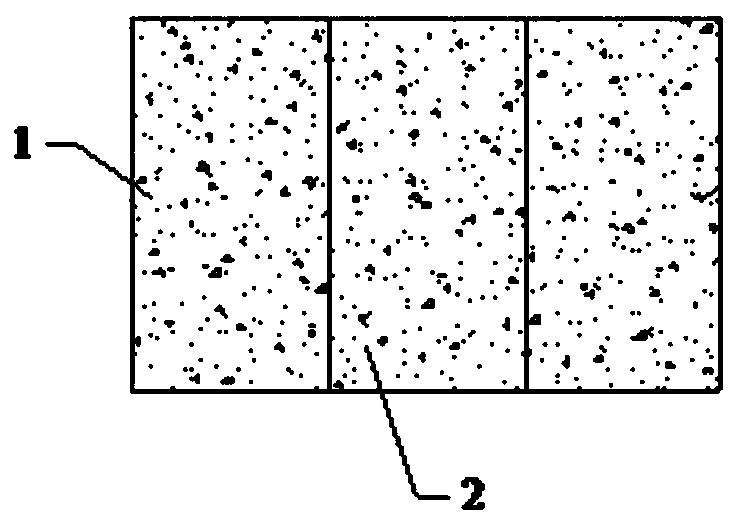

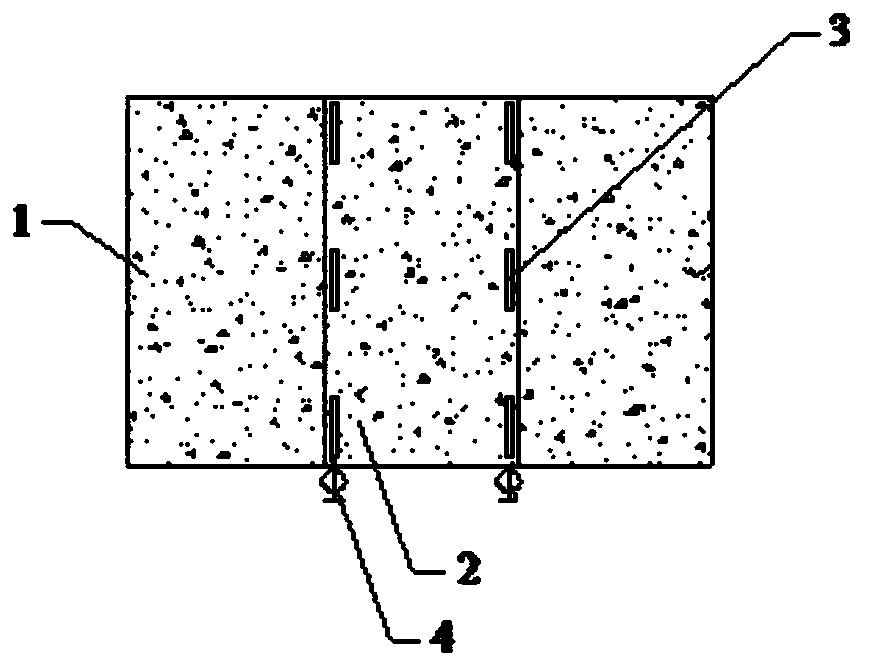

[0050] S2. Pouring new concrete specimen 2 between two old concrete specimens 1, two old concrete specimens 1 and new concrete specimen 2 are used as poured complete test specimens, as attached figure 1 As shown, the new concrete specimen 2 is poured after the old concrete specimen 1 is hoisted and fixed; the length L of the new concrete specimen 2 1 , width L 2 and height L 3 The length, width and height of the old concrete specimen 1 are the same respectively; Carry out chiseling treatment; after chiseling treatment, use a hair dryer to blow off the concrete debris, rinse it with clean water and keep the joint surface moist until pouring new concrete specimen 2. as attached image 3 As shown, a steel ...

Embodiment 2

[0066] Taking an old concrete specimen with a length of 20cm, a width of 40cm, and a height of 50cm as an example, the details are as follows:

[0067] (1), prefabricated old concrete specimen 1, the length, width and height are 20cm, 40cm, and 50cm respectively;

[0068] (2), hoist the old concrete test piece 1 to the steel support 7 and put it in place, and fix the old concrete test piece 1 with the steel backing plate 5 and 4 fixing bolts 6; wherein, the steel backing plate 5 is located on the old concrete test piece 1, the steel support 7 is at the bottom;

[0069] (3) Use a chisel hammer to chisel 2 pieces of old concrete specimen 1 at the joint surface, then use a blower to blow off the residual and loose concrete debris, rinse it with drinking water and keep the joint surface moist, Formwork is erected between two pieces of old concrete, and new concrete specimen 2 is poured to form a test specimen. After the curing is completed, the formwork is removed, and the fabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com