Rock mass fracture unsaturated seepage test system

A rock mass fissure and test system technology, applied in the field of rock mass seepage, can solve the problems that hydraulic parameters cannot be directly used for analysis, etc., and achieve the effects of ensuring stability, expanding the test range, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

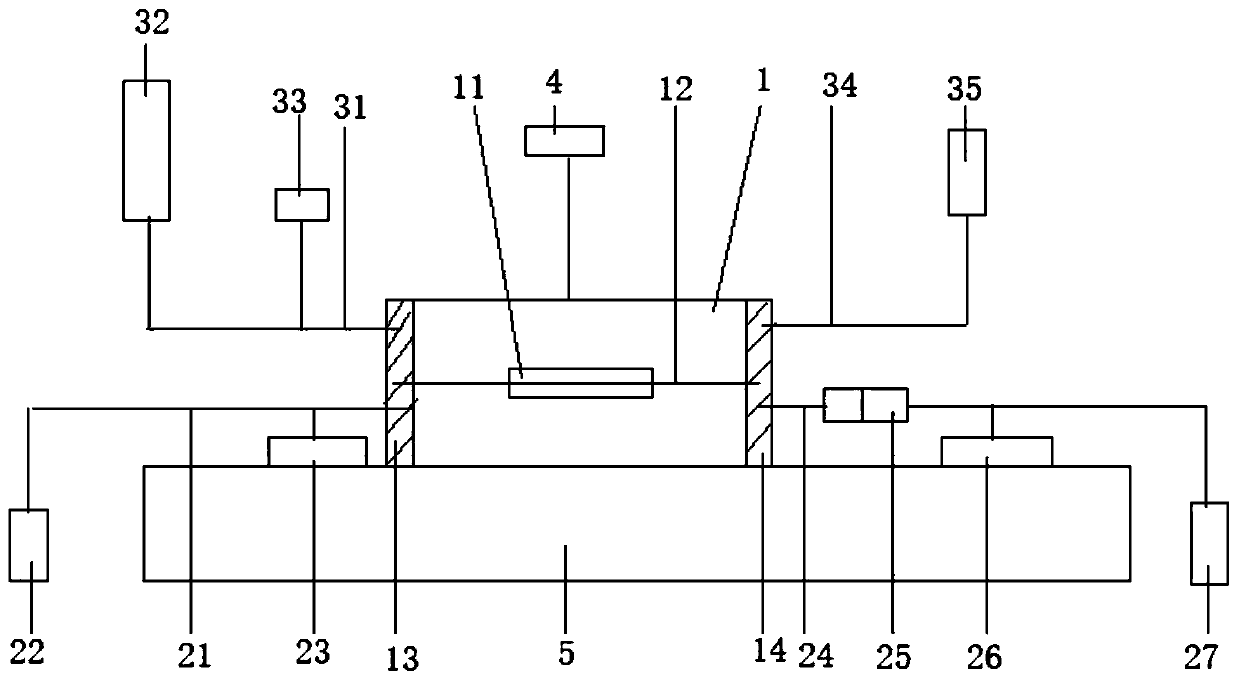

[0031] Please see figure 1 , is a structural schematic diagram of a preferred embodiment of a rock mass fissure unsaturated seepage test system of the present invention, a rock mass fissure unsaturated seepage test system, which is characterized in that it includes a clamper for clamping the fissure rock mass 11 12. The test box 1 where the holder 12 and the fractured rock mass 11 are placed, the temperature control device and the pressure sensor in the test box 1, the first end cap 13 and the second end cap 14 on both sides of the test box 1, through the water inlet pipe 21 The solution bottle 22 to be tested connected to the first end cap 13, the high-pressure metering pump a23 between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com