Supercapacitor capacity detection method

A supercapacitor, capacity detection technology, applied in capacitance measurement, measurement of electrical variables, instruments, etc., can solve the problems of low efficiency, high labor cost, low detection accuracy, etc., to improve detection efficiency, reduce labor costs, fast and automatic The effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

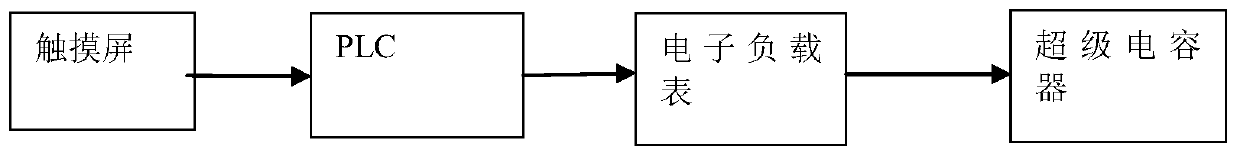

[0020] like figure 1 and figure 2 As shown, the supercapacitor capacity detection method of the present invention comprises steps:

[0021] A1. Build a detection circuit consisting of a touch screen, a programmable logic controller and an electronic load meter, wherein the touch screen, the programmable logic controller and the electronic load meter are connected in sequence, and the electronic load meter is connected to the to-be-detected capacitor;

[0022] A2. Write the parameters for detecting the capacitor into the programmable logic controller;

[0023] A3. The programmable logic controller controls the electronic load meter to measure the capacitor according to the parameters;

[0024] A4. The electronic load meter transmits the measurement result to the programmable logic controller, and the programmable logic controller calculates the capacity of the capacitor according to the measurement result.

[0025] According to an embodiment of the present invention, it fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com