Method for automatically measuring angle on equipment

An automatic measurement and angle measurement technology, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of large human influence factors, limited measurement ability, low processing efficiency, etc., to improve the utilization rate of machine tools , The measured value is accurate and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

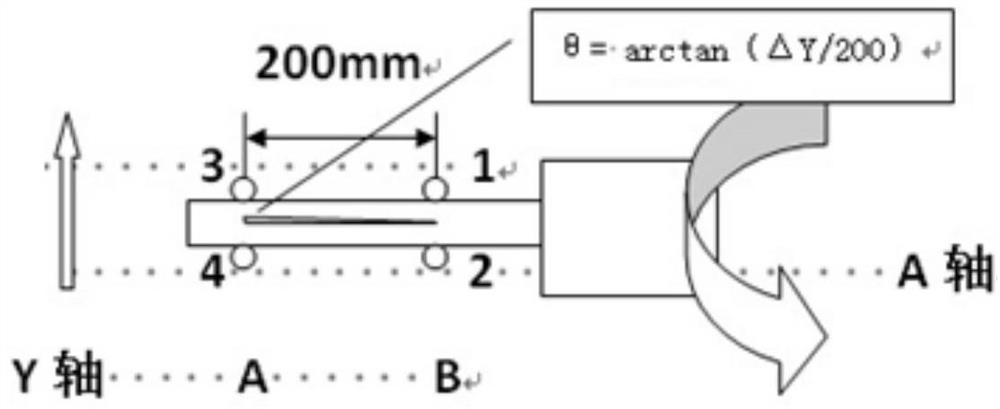

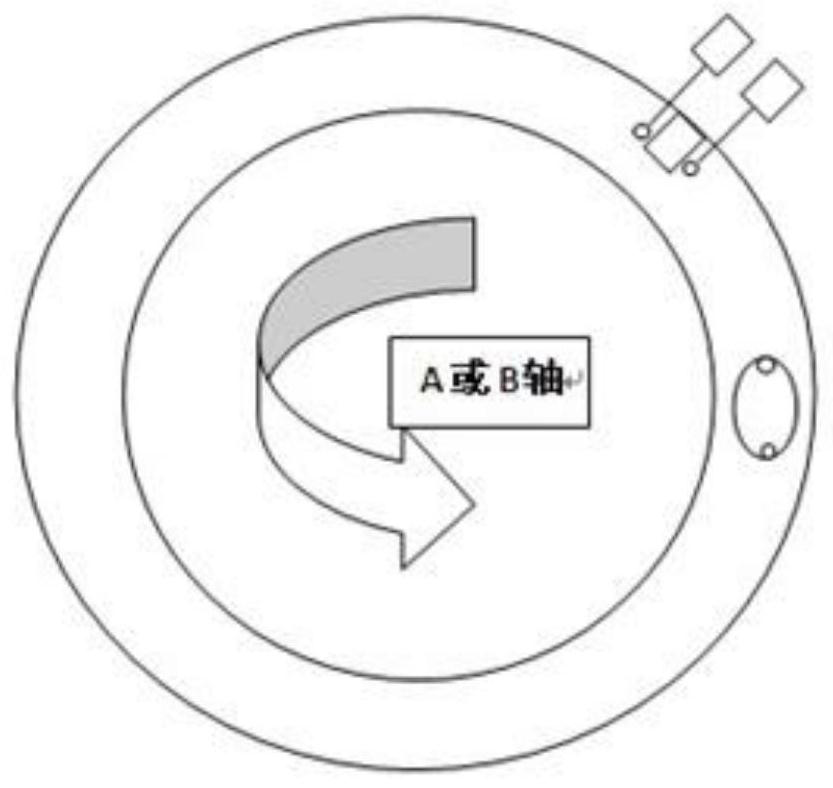

[0019] The invention provides an automatic angle measurement method on equipment, which is characterized in that: the automatic angle measurement method on equipment analyzes the structure of the numerical control machine tool and the processing technology of parts, analyzes the measurement method for the characteristic elements of angle measurement, and determines the moving axis. Data extraction axis, so as to establish the feature measurement plan; according to the angle feature measurement plan, establish a feature measurement model, classify the features, and compile a modular feature measurement program for different features; for different part features, only need to simply modify the parameters. Realize fast switching of different feature measurement programs; use the most basic signal programming method of the infrared or Bluetooth probe of the CNC machining center, so that the program can adapt to equipment from different manufacturers, and perform online measurement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com