Real-time hybrid test method based on actuator and vibration table

A hybrid test and shaking table technology, which is applied in the field of civil engineering, can solve problems such as the lack of effective and reliable solutions, the difficulty of ensuring high-precision reproduction of boundary conditions, and the difficulty of ensuring stable force control accuracy, so as to achieve the best displacement goals , Simplify the difficulty of dynamic force control and reduce the effect of test difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

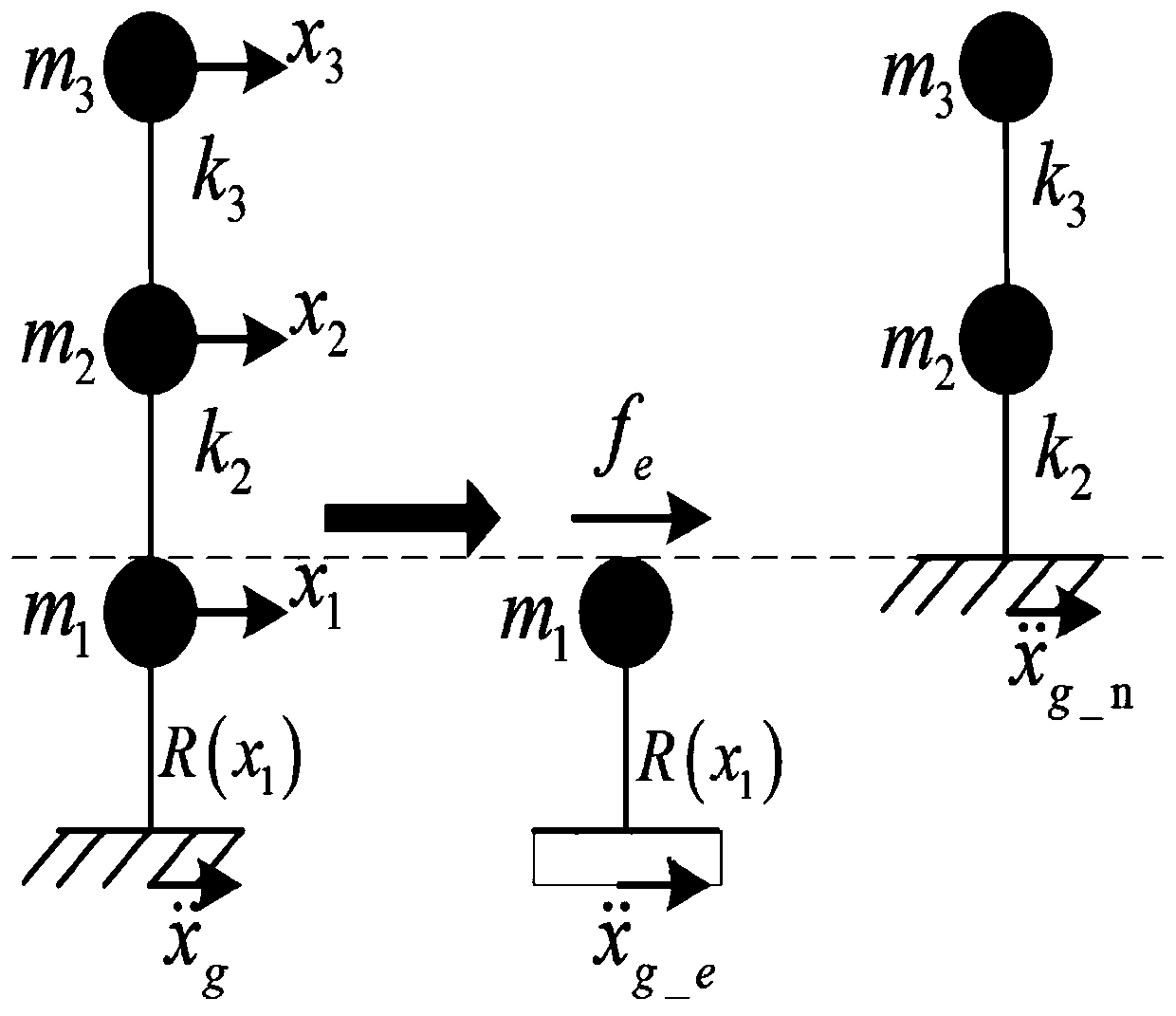

[0057] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 To illustrate this embodiment, the real-time mixed test method described in this embodiment is to establish the numerical substructure dynamic equation and the experimental substructure dynamic equation respectively after the numerical substructure and experimental substructure of the structural model are divided, and logarithmically The numerical calculation of the structural dynamics equation is carried out using the numerical integration algorithm, and the loading of the test substructure is carried out by the loading equipment, so that the calculation results of the numerical integration algorithm can be used as the loading command of the loading equipment in real time and the relevant quantities collected by the acquisition equipment can be used as the numerical substructure. Numerical calculations of the inputs to the mixed test procedure.

[0058] ...

specific Embodiment approach 2

[0061] Specific embodiment two: this embodiment is a further limitation of specific embodiment one, such as figure 2 As shown, after the numerical substructure and test substructure of the structural model are divided, the test substructure is loaded by displacement-controlled loading.

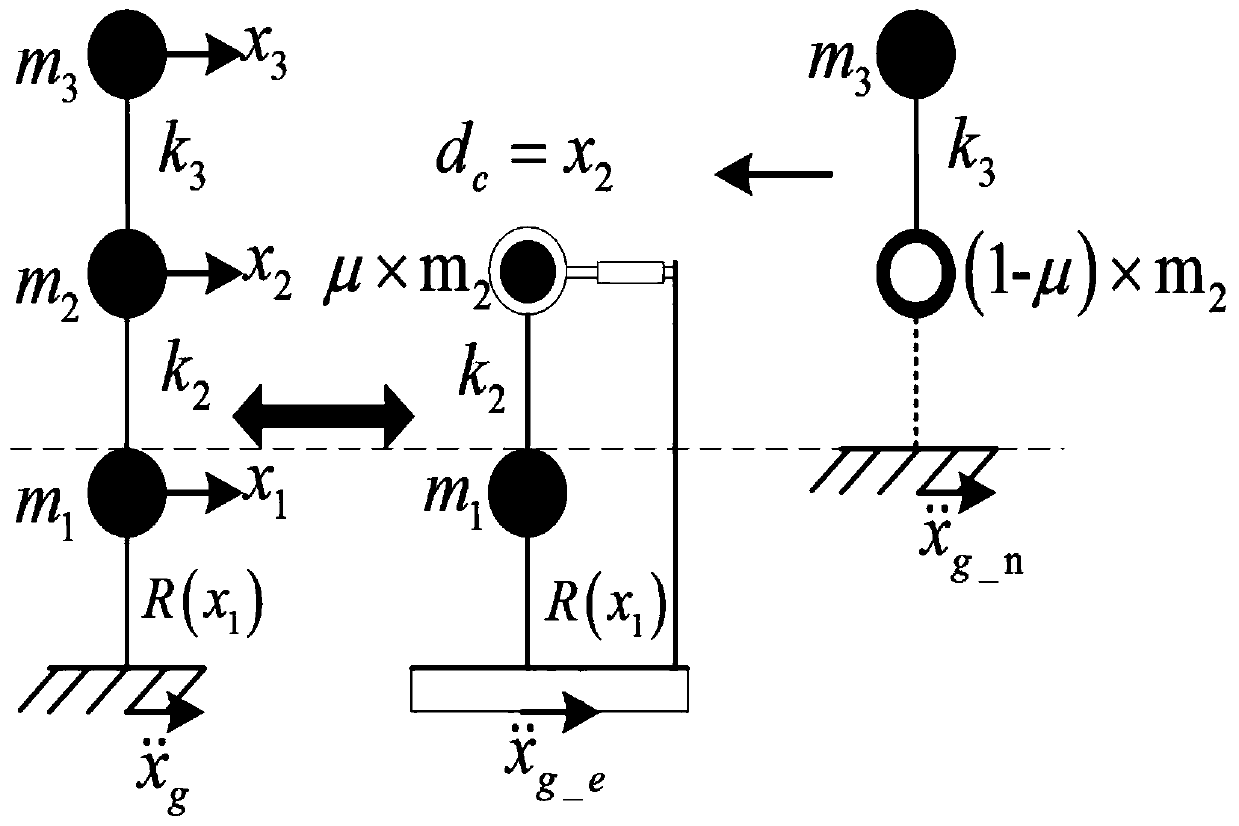

[0062] In this embodiment, the division method of the structural model is a new division method. Taking the three-layer shear structure as an example, the new substructure division form is given. When the displacement control loading method is used to load the test substructure, figure 2 In the shown structure, from left to right are the original structure, experimental substructure and numerical substructure. The position of the dotted line in the figure indicates the division position of the first division method. Different from the first division method, the new substructure division affects the The division method of numerical substructure and experimental substructure is that the first ...

specific Embodiment approach 3

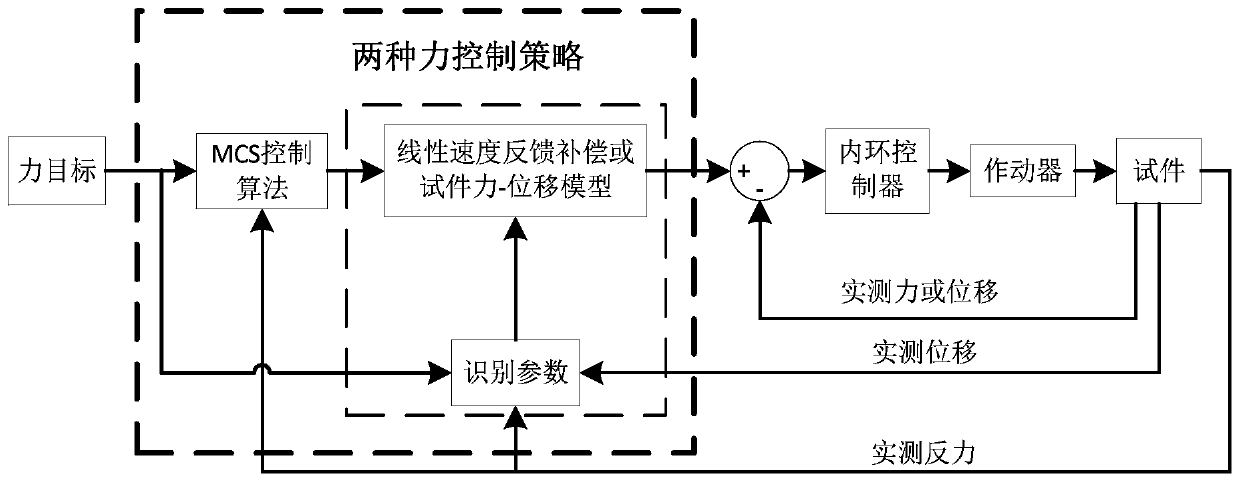

[0065] Specific embodiment three: this embodiment is a further limitation of specific embodiment one or two, such as figure 1 As shown, after the numerical substructure and test substructure of the structural model are divided, when the test substructure uses the force-controlled loading method to load the loading equipment, a controller is added to the outer ring of the model, which is specifically divided into the following two steps :

[0066] Step 1: Use the least squares algorithm to identify the model parameters of the specimen or the least mean square algorithm to identify the linear velocity feedback compensation parameters to achieve preliminary control;

[0067] Step 2: The minimum control synthesis algorithm is used to adapt to redundant nonlinearity and parameter changes, so as to realize the dynamic force uniaxial loading control strategy.

[0068] When the test substructure is loaded by the force-controlled actuator, it means that the test substructure is loaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com