Electric wire with terminal and method for manufacturing electric wire with terminal

A terminal and wire technology, which is applied in the field of wires with terminals, can solve the problems of accelerating the damage of wires and terminals, reducing the electrical performance of the connection, damaging cables and equipment, etc., to improve product quality, prevent oxidation or rust, and reduce resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

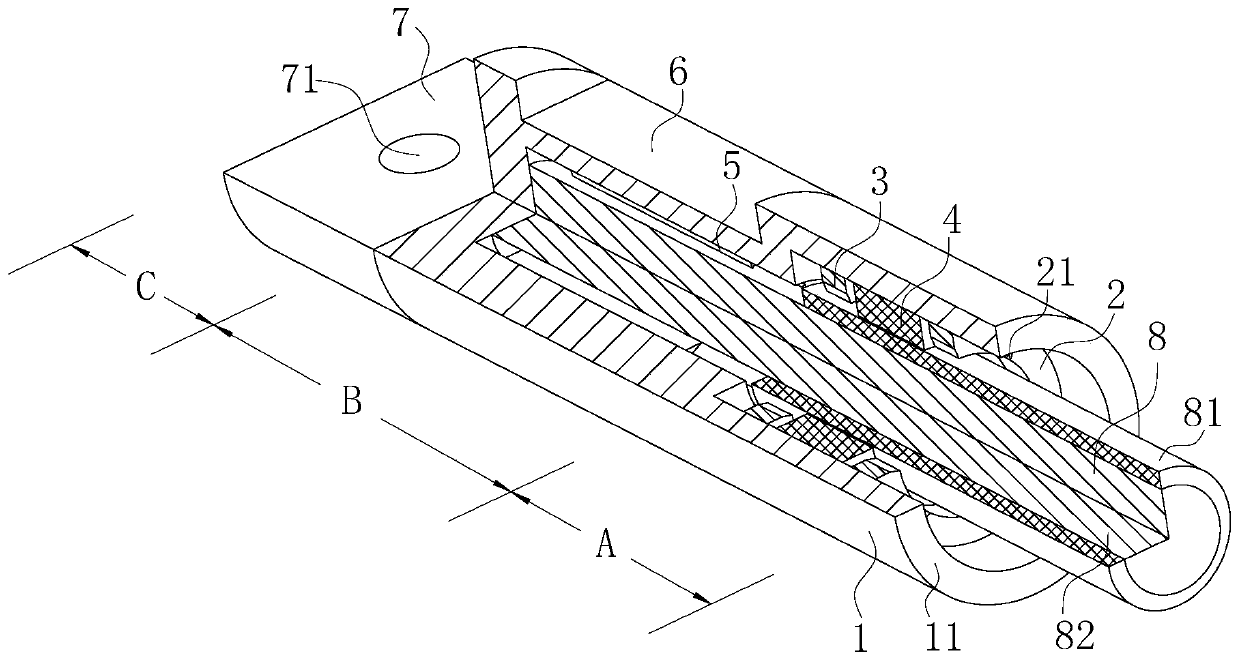

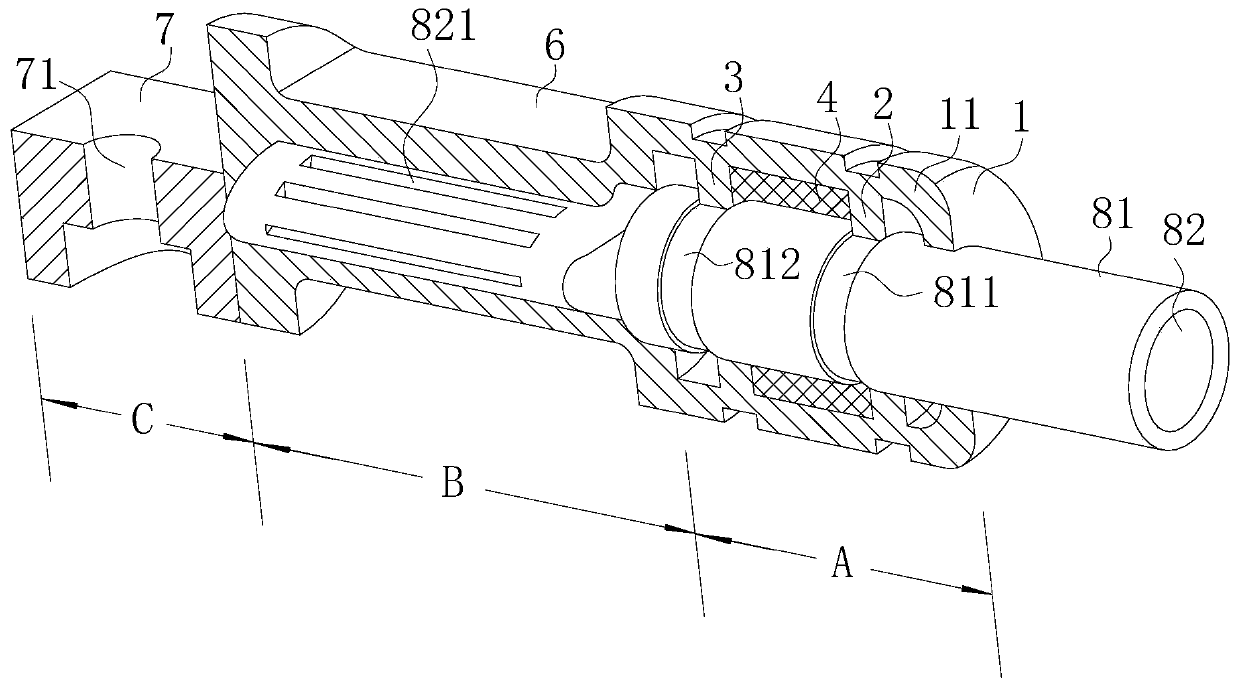

[0025] As an embodiment of the present invention, the outer casing 11 is provided with triangular projections 5; the triangular projections 5 are evenly distributed on the inner wall of the deep hole in the outer casing 11; The axial direction of the body 11 is the same; the triangular protrusion 5 is located on the core connection section B on the outer shell 11; the tip of the triangular protrusion 5 just touches the surface of the conductive core 82 of the cable 8; After the conductive wire core 82 is inserted into the outer casing 11, the surface of the conductive wire core 82 contacts the tip of the triangular protrusion 5, and then the terminal 1 is pressed tightly with a tool, so that the triangular protrusion 5 is inserted into the conductive wire core 82, so that the triangular protrusion 5 The contact area between 5 and the conductive wire core 82 becomes larger, and at the same time, the triangular protrusion 5 can better clamp the conductive wire core 82 to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com