Transplanting robot suitable for hydroponic seedlings

A robot and hydroponic technology, applied in the direction of transplanting machinery, cultivation, manipulators, etc., can solve the problems of high labor intensity, complex structure, low efficiency, etc., and achieve the goal of reducing labor costs, improving transplanting efficiency, and improving grasping accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

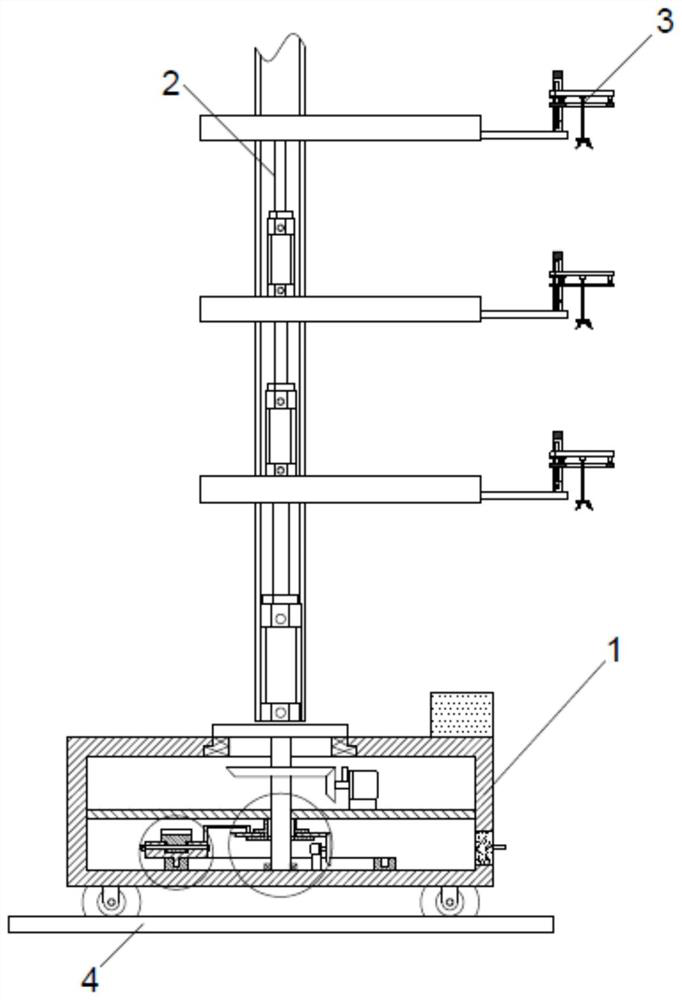

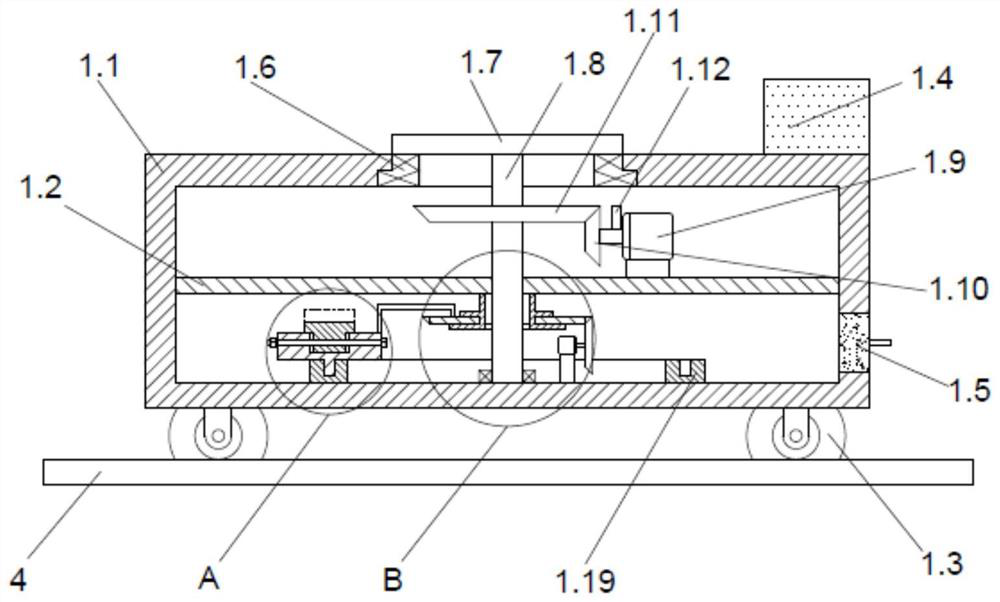

[0045] see Figure 1-17 , the embodiment of the present invention provides a transplanting robot suitable for hydroponic seedlings, AGV logistics trolley 1, mechanical arm 2 and hydroponic sponge grabbing device 3, AGV logistics trolley 1 includes bottom box 1.1, guide wheel 1.3 and guide rail 4, The bottom of the bottom box 1.1 is provided with a number of guide wheels 1.3, and guide rails 4 are laid between the hydroponic racks in the greenhouse. The guide wheels 1.3 are matched with the guide rails 4. The drive system for driving the AGV logistics trolley 1 is the prior art, so it will not be described here. repeat.

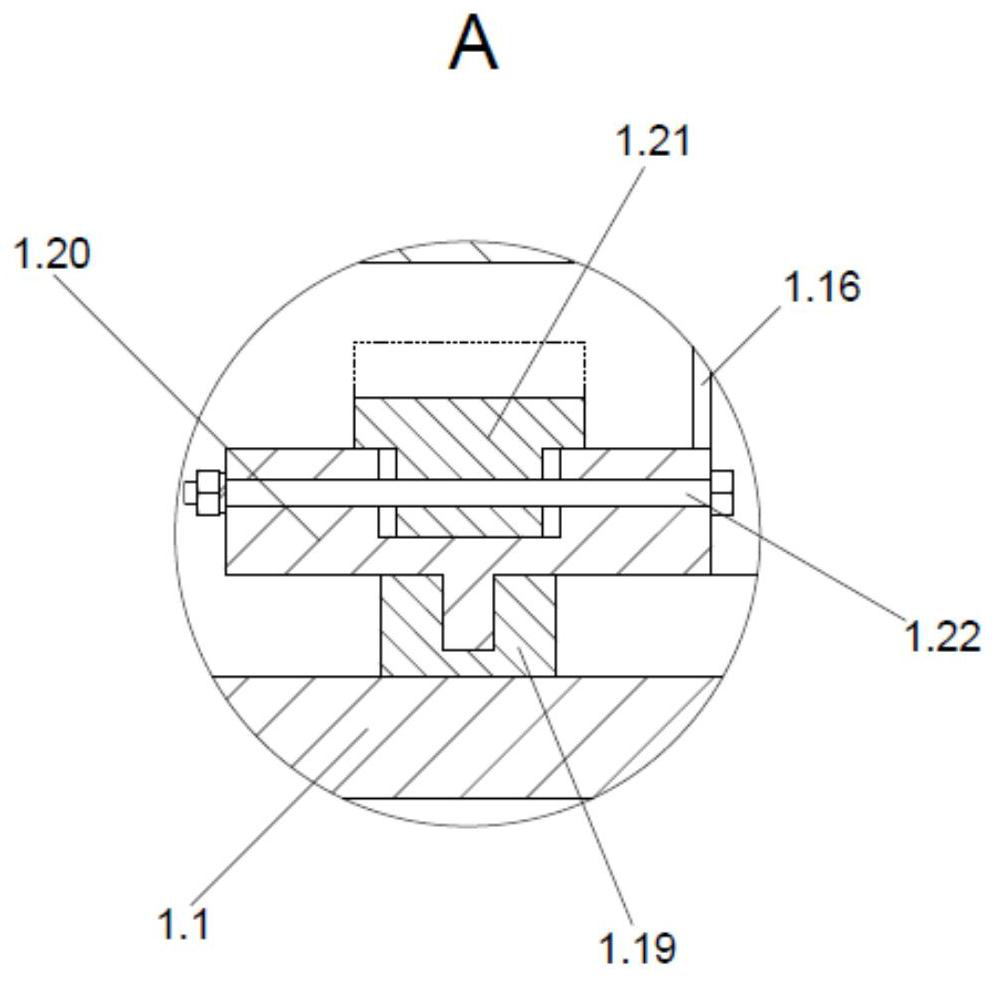

[0046] The middle part of the bottom box 1.1 is provided with a middle partition 1.2, the middle partition 1.2 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com