Vacuum diffusion welding connection method for molybdenum-based superalloy

A technology of vacuum diffusion welding and high temperature alloys, applied in welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of unqualified weld quality, cracks and pores, etc., to increase the holding time, control welding cracks, and reduce roughness. The effect of grain generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

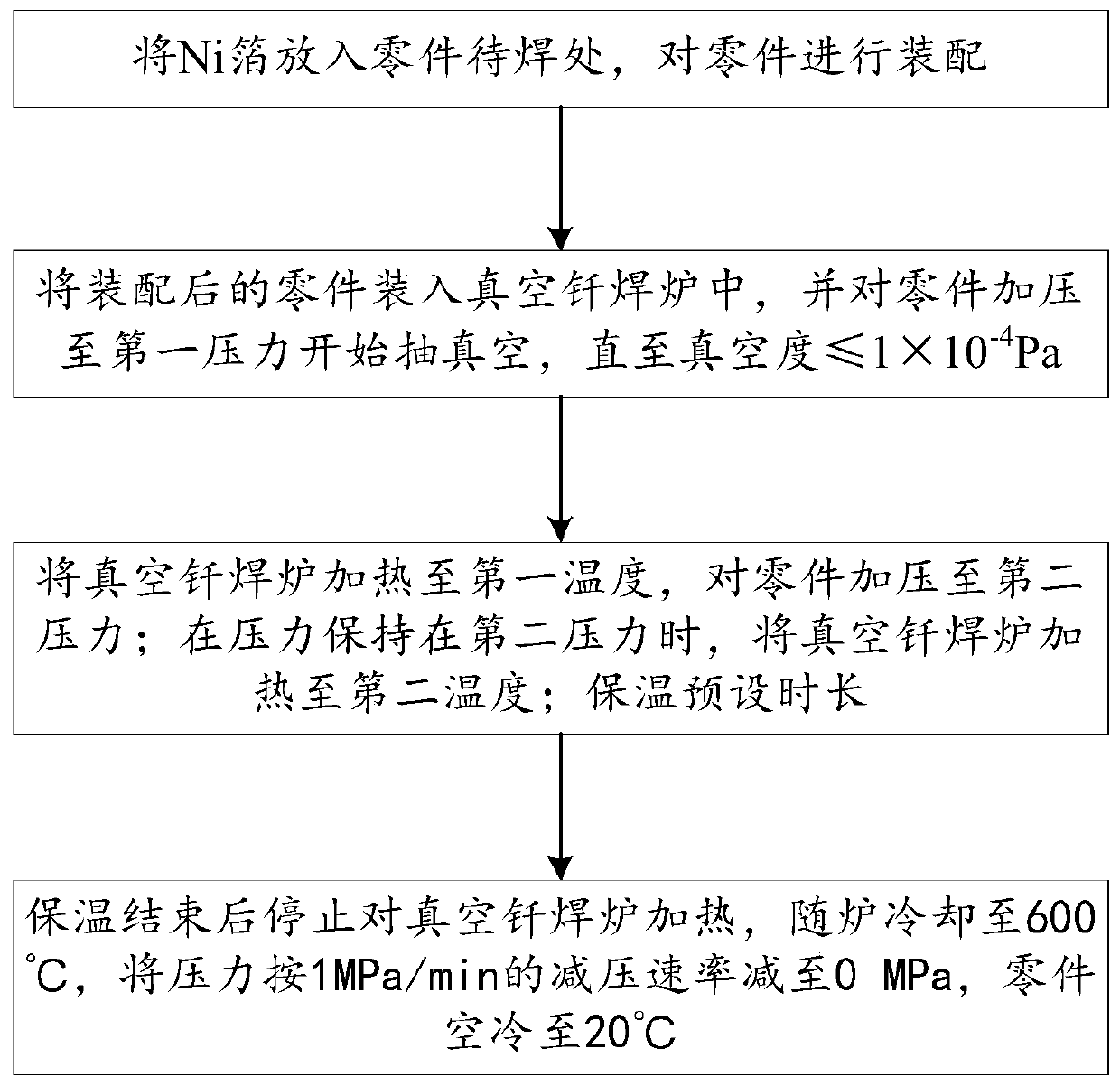

[0035] Its specific implementation is as follows:

[0036] 1. Use 800 mesh sandpaper for mechanical polishing to remove surface oxides;

[0037] 2. Ultrasonic cleaning of parts to be welded to remove oil and other dirt on the surface to be welded;

[0038] 3. Put the 50um Ni foil into the parts to be welded, and the gap between the welds after assembly is (0.005-0.01)mm;

[0039] 4. Put the parts into the vacuum brazing furnace, pressurize to 2MPa and start vacuuming until the vacuum degree is ≤1×10 -4 Pa;

[0040] 5. After reaching the degree of vacuum, heat to 900°C at a heating rate of 25°C / min. After reaching 900°C, increase the pressure to 5MPa at a pressurization rate of 0.3MPa / min, and maintain 900°C during the process;

[0041] 6. Pressurize to 5MPa, heat to 1100°C at a heating rate of 10°C / min, keep the temperature for 30min, and maintain a pressure of 5MPa during the process;

[0042] 7. Stop heating after the heat preservation is over, cool down to 600°C with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com