Prepressing machine for plywood production line

A technology for plywood and production lines, applied in the field of pre-pressing machines, can solve the problems of bulging of the surface of the plate, low pre-pressing efficiency of the plate, failure of plate production, etc., so as to reduce the attachment area, save the pre-pressing time, and reduce the adhesion area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

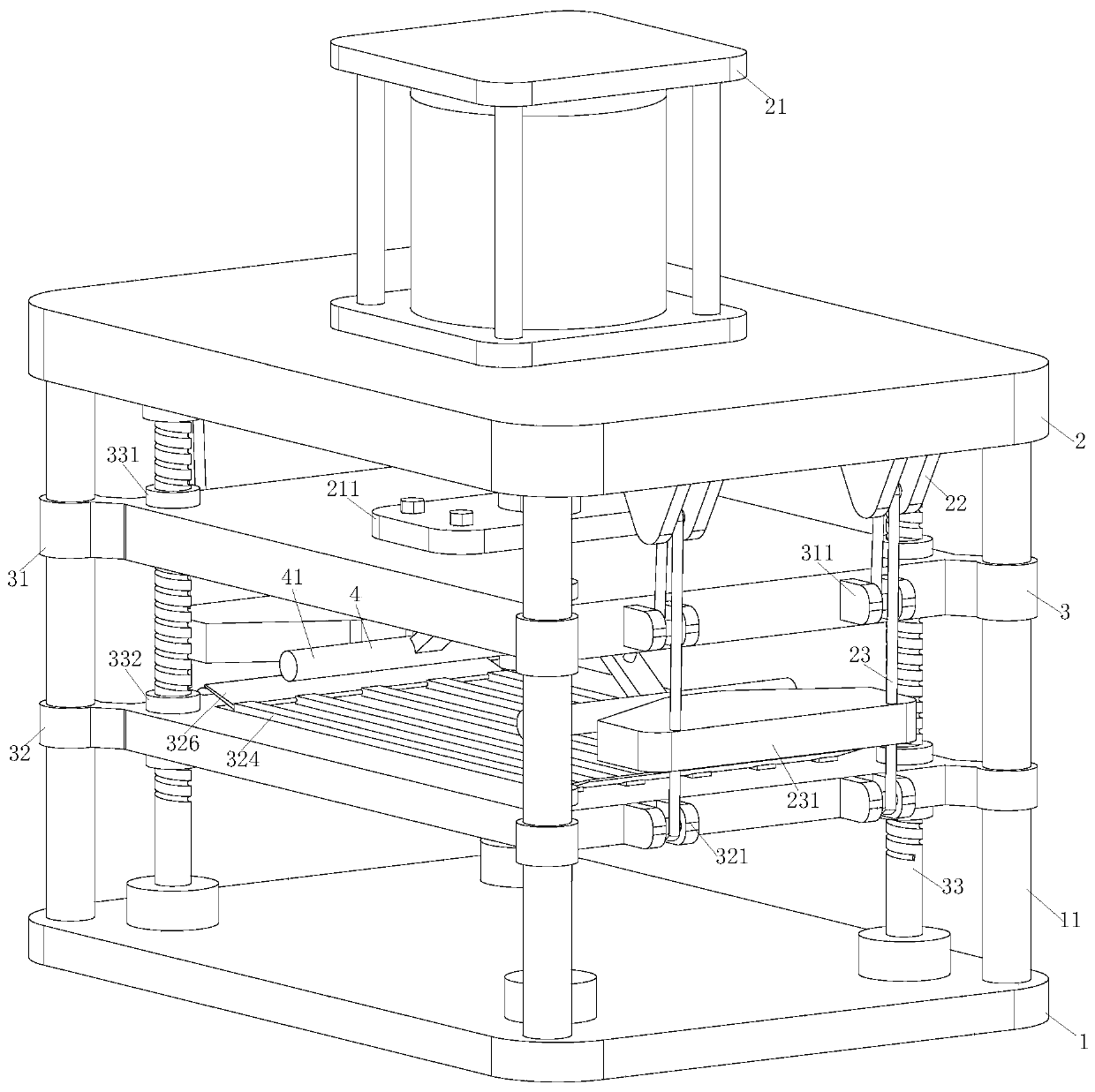

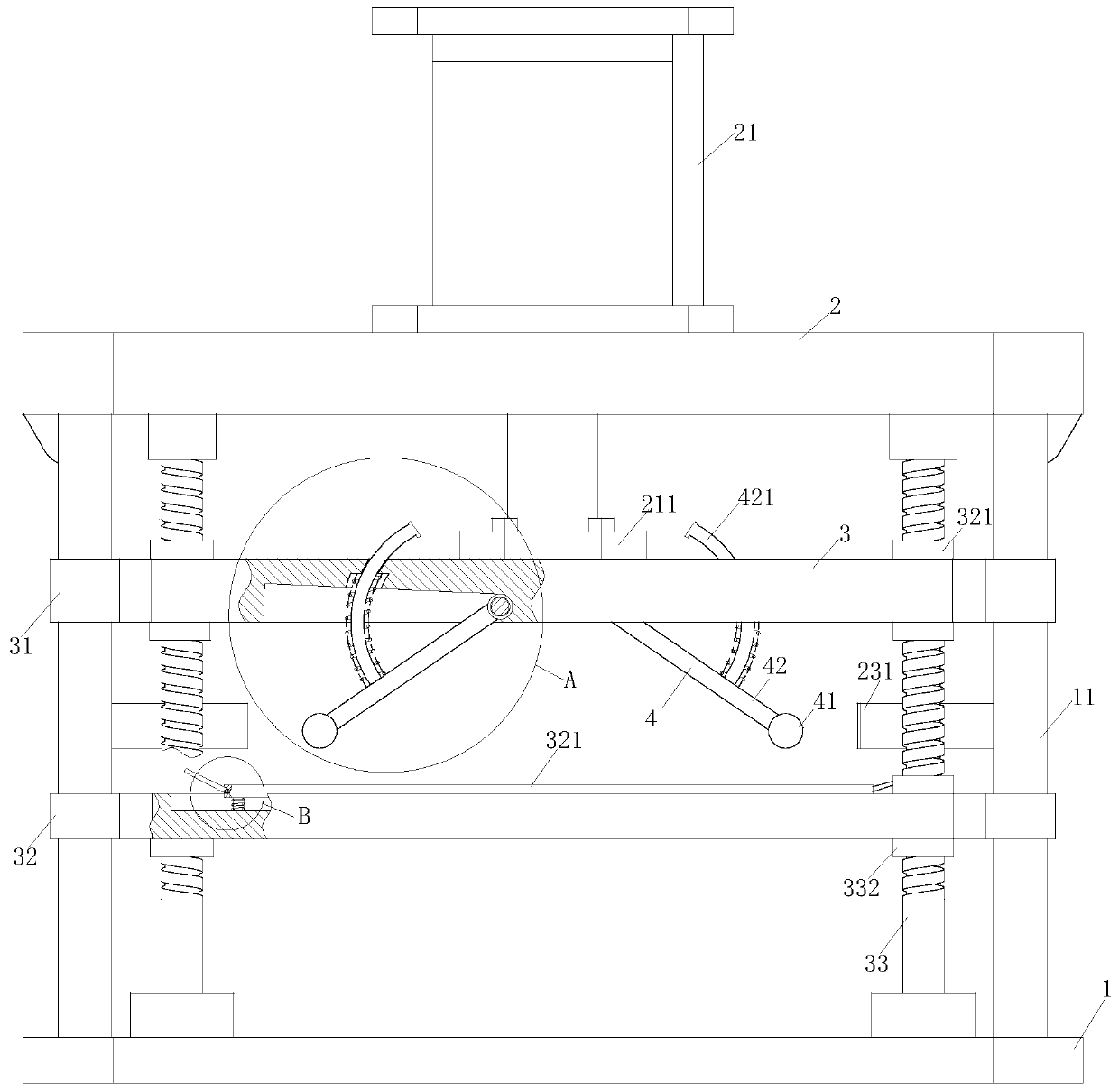

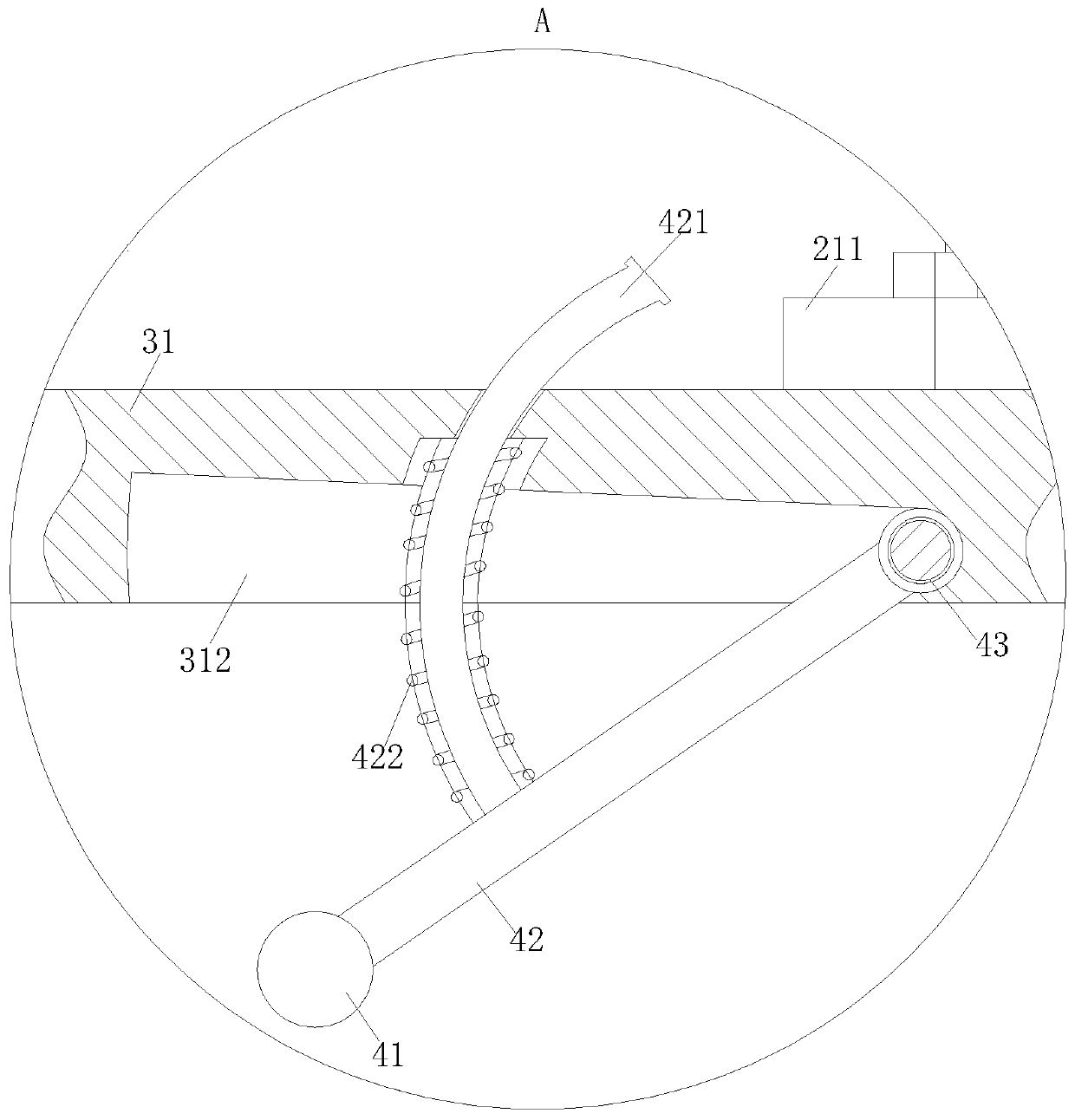

[0024] As a specific embodiment of the present invention, the lower surface of the support plate 2 is symmetrically provided with a plurality of transition hooks 22, and below each transition hook 22 is a No. 1 hook 311, and each No. 1 hook 311 is fixed on On the side of the driving plate 31, below each No. 1 hook 311 is a No. 2 hook 321, and each No. 2 hook 321 is fixedly connected to the side of the driven plate 32. Each No. 2 hook 321 is bolted with a wire rope 23. One end, the wire rope The other end of 23 passes through the transitional hook 22, and is tethered on the No. 1 hook 311, and a push plate 231 is provided between adjacent steel wire ropes 23; The cooperation between the active plate 31 and the driven plate 32 strengthens the extrusion force on the plywood again; when the active plate 31 and the driven plate 32 move towards each other and approach at the same time, the No. 1 hook 311 on the active plate 31 pulls the wire rope 23 One end, then the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com