Non-flaring guide pipe connector extrusion molding device

A technology for connecting extrusion and molding equipment, which is applied in the field of mechanical design and manufacturing, extrusion molding processing machinery design and manufacturing, can solve problems such as insufficient control, product pinching, and lack of support, so as to reduce labor intensity and solve replacement problems. Trouble, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0045] In conjunction with the accompanying drawings.

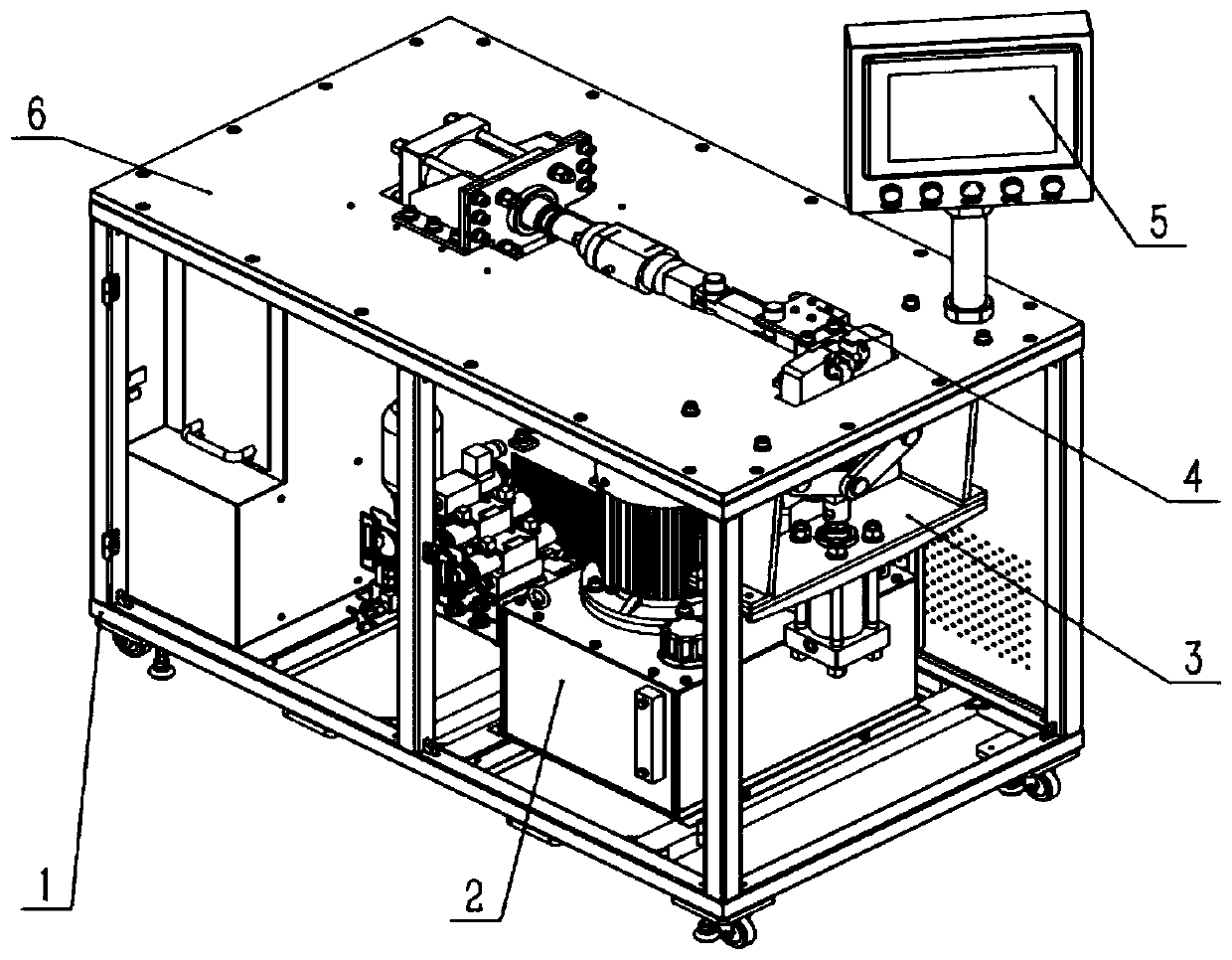

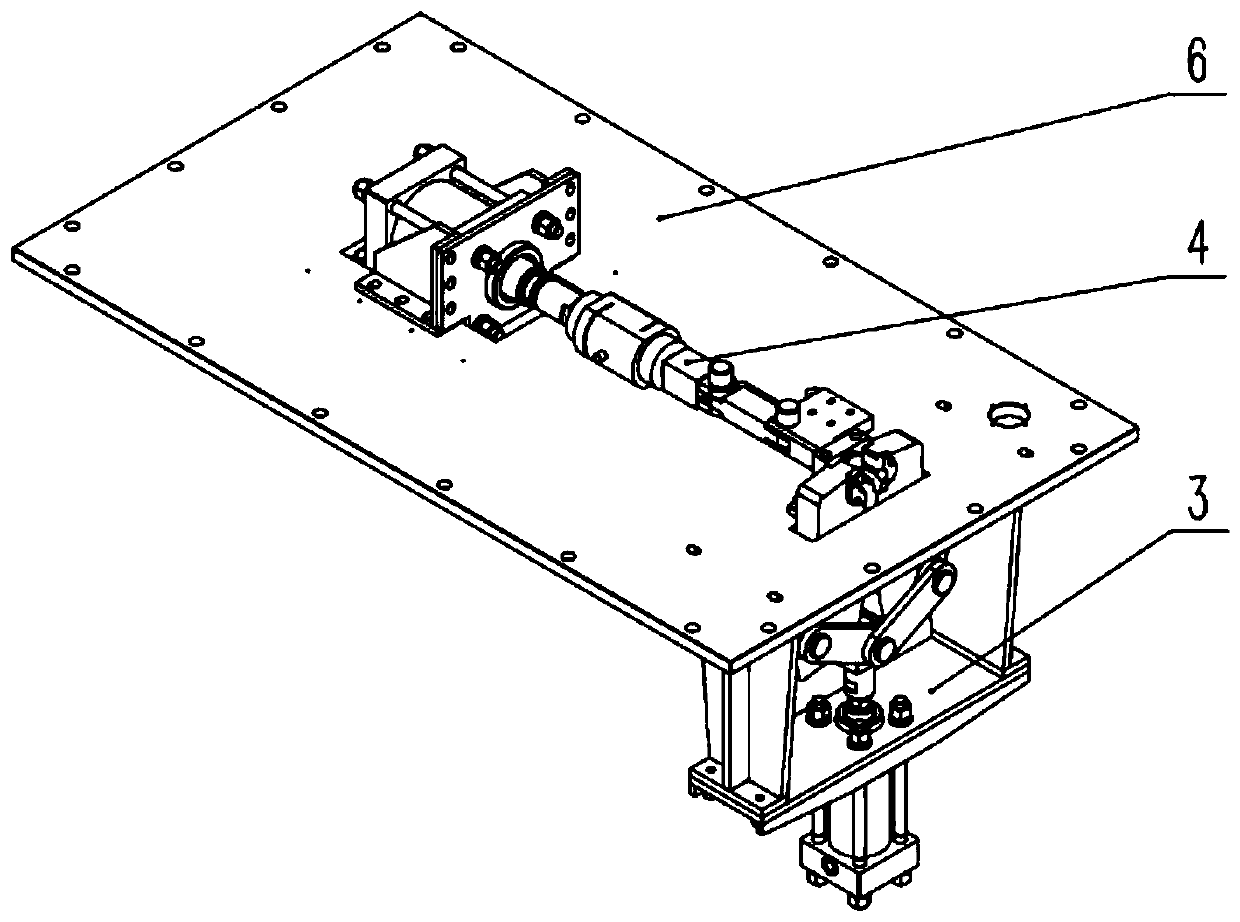

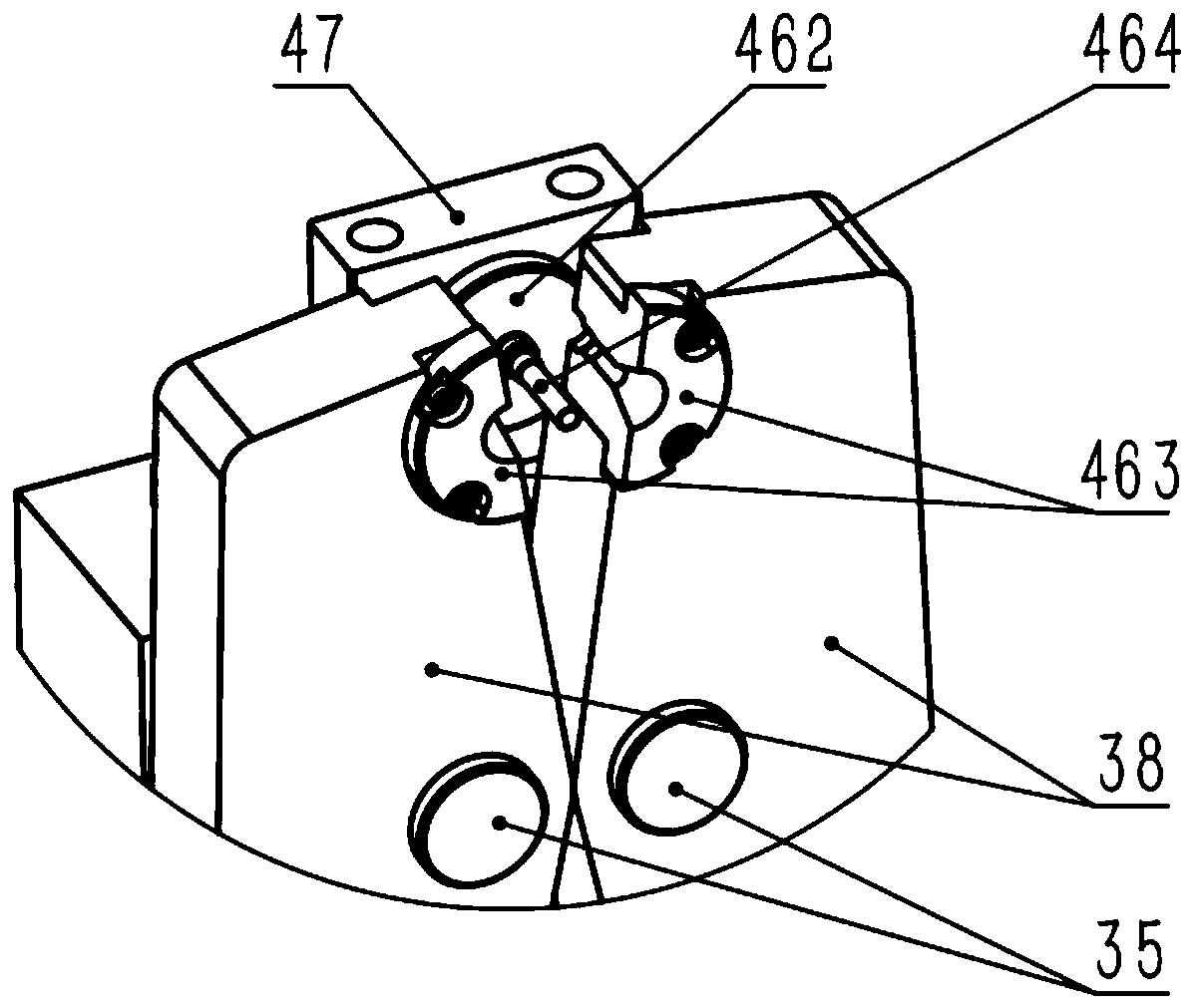

[0046] The equipment of the present invention includes a cabinet 1 , a hydraulic system 2 , a clamping mechanism 3 , a stretching mechanism 4 , an operation panel 5 and a working platform 6 .

[0047] The frame of the cabinet 1 is also provided with an electric control box 11 and a hydraulic system 2; both the electric control box 11 and the hydraulic system 2 are fixed in the frame of the cabinet 1 by screws or bolts; when necessary, the electric control box 11 and the hydraulic system 2 can be Take it out from the cabinet 1 frame during maintenance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com