Color-changing knitted fabric

A knitting fabric and coloring technology, applied in knitting, weft knitting, warp knitting, etc., can solve the problems of slow knitting speed, small stock in the market, and heavy finished fabrics, and achieve rich and changeable colors. Good performance and stable physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

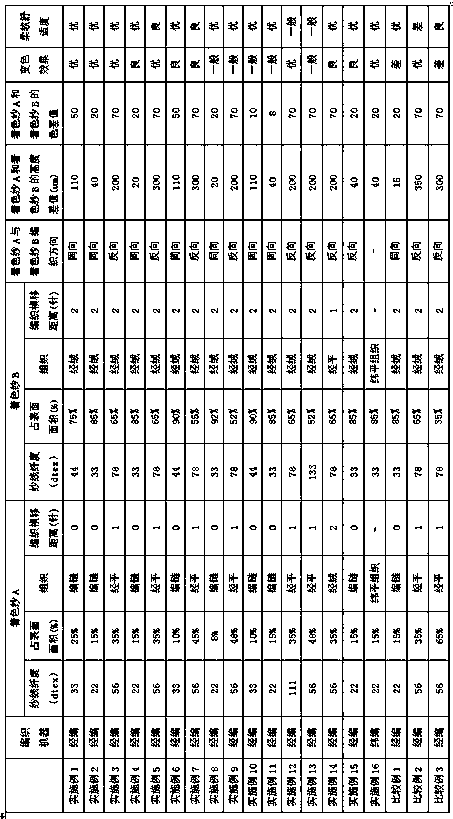

[0047] Colored yarn A uses 33dtex-24f-cationic FDY, accounting for 25% of the surface area, knitting chain structure, knitting traverse is 0 stitches; colored yarn B uses 44dtex-34f-nylon FDY, accounting for 75% of the surface area, after Pile fabric, knitting traverse is 2 needles, colored yarn A and colored yarn B are knitted in the same direction, the knitting traverse pitch of colored yarn A is smaller than that of colored yarn B, and colored yarn A is in the lateral direction of the fabric It is 110um higher than colored yarn B, and the color difference between colored yarn A and colored yarn B is 50.

[0048] The properties of the obtained fabric are shown in Table 1.

Embodiment 2

[0050] Colored yarn A uses 22dtex-24f-cationic FDY, accounting for 15% of the surface area, knitting chain structure, knitting traverse is 0 stitches; colored yarn B uses 33dtex-24f-nylon FDY, accounting for 85% of the surface area, after Pile fabric, knitting traverse is 2 needles, colored yarn A and colored yarn B are knitted in the same direction, the knitting traverse pitch of colored yarn A is smaller than that of colored yarn B, and colored yarn A is in the lateral direction of the fabric It is 40um higher than colored yarn B, and the color difference between colored yarn A and colored yarn B is 20.

[0051] The properties of the obtained fabric are shown in Table 1.

Embodiment 3

[0053] Colored yarn A uses 56dtex-24f-cationic FDY, which accounts for 35% of the surface area, and is warped through plain weave, and the weaving traverse is 1 needle; colored yarn B is made of 78dtex-24f-nylon FDY, which accounts for 65% of the surface area, and is warp Pile weave, knitting traverse is 2 needles, colored yarn A and colored yarn B are reverse knitting, the knitting traverse pitch of colored yarn A is smaller than that of colored yarn B, and colored yarn A is in the lateral direction of the fabric It is 200um higher than colored yarn B, and the color difference between colored yarn A and colored yarn B is 70.

[0054] The properties of the obtained fabric are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com