An automatic avoidance type rail snow clearing device that can run synchronously with the train

A synchronous operation and automatic avoidance technology, applied in track cleaning, cleaning methods, buildings, etc., can solve the problems of low efficiency of snow removal, synchronous operation, and hidden dangers of train safety, so as to increase the time of snow removal and improve automation. degree, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

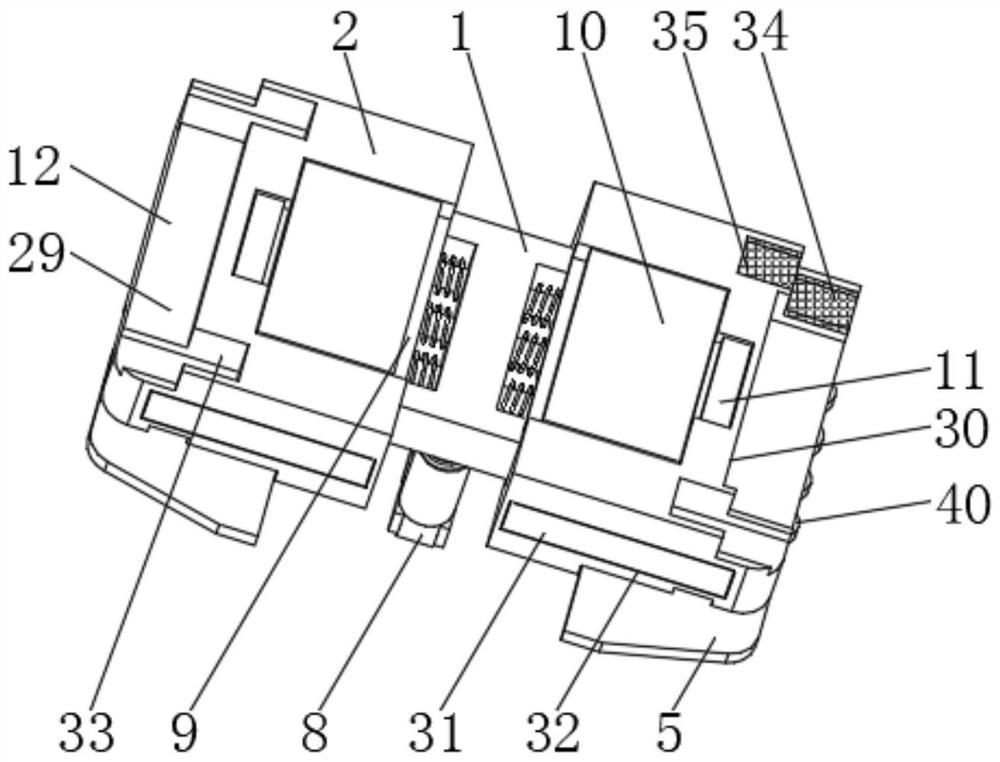

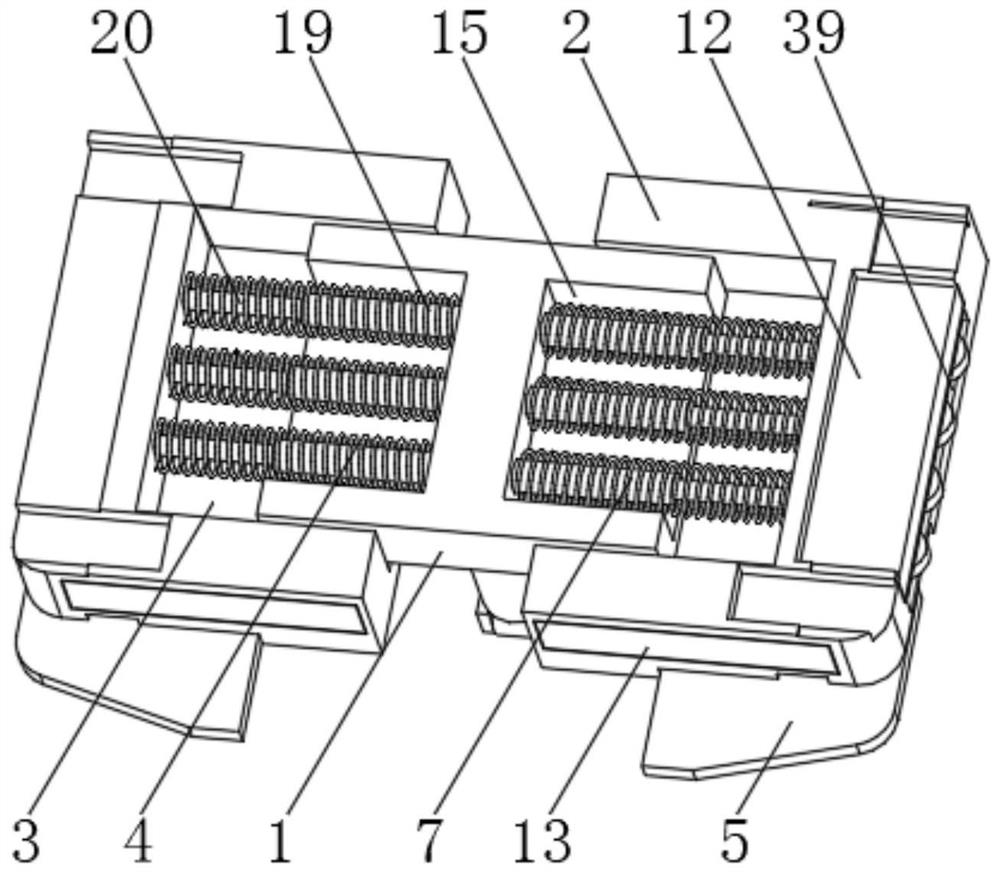

[0026] see Figure 1-3 , the present invention provides a technical solution: an automatic avoidance type rail snow clearing device capable of running synchronously with trains, comprising a middle plate 1, two ends of the middle plate 1 are provided with a working plate 2, and one of the working plates 2 There is a chute 3 matching the middle plate 1 on the side. Both ends of the middle plate 1 extend to the inside of the chute 3 and are slidably connected with the inner wall of the chute 3. Both ends of the middle plate 1 are provided with linkage Groove 15, one side of the inner wall of the interlocking groove 15 is fixedly connected with the inner wall of the chute 3 through the interlocking device 7, the inner wall of the middle plate 1 and the chute 3 is fixedly connected by the support spring 4, and the working plate 2 is far away from the middle plate 1 One side of the arc groove 14 is provided with an arc groove 14, and the bottom of the arc groove 14 is provided with...

Embodiment 2

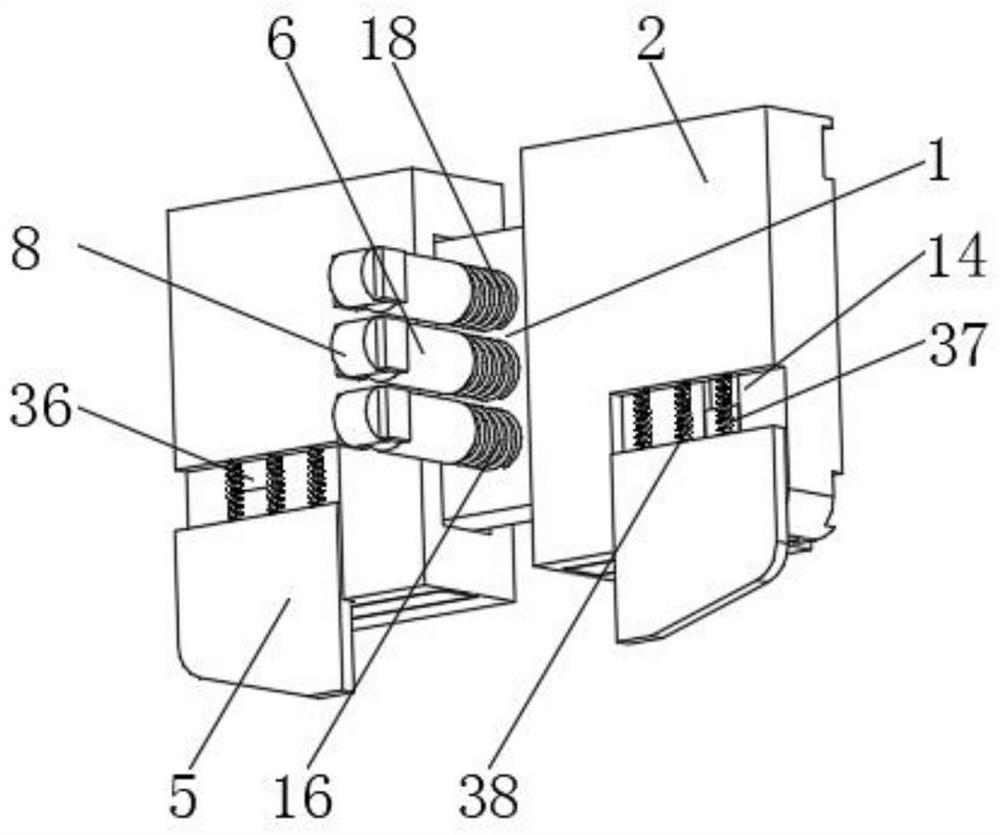

[0029] see Figure 1-4, the present invention provides a technical solution: on the basis of Embodiment 1, the side of the working plate 2 away from the middle plate 1 is provided with an arc groove 14, and the bottom of the arc groove 14 is provided with a slider groove 36, and the slider groove Slide block 37 is slidably connected between the inner wall both sides of 36, and slide block 37 extends to one end outside slide block groove 36 and is fixedly connected with arc plate 5, and one side of arc plate 5 is connected with arc groove 14 by buffer spring 38. One side of the inner wall of the interlocking groove 15 is fixedly connected with the inner wall of the chute 3 through the interlocking device 7, and the outer side of the communicating device 7 is provided with a supporting spring 4, and the two ends of the supporting spring 4 are respectively connected to the middle plate 1 It is fixedly connected with the inner wall of the chute 3, the bottom of the middle plate 1 ...

Embodiment 3

[0032] see Figure 1-3 , the present invention provides a technical solution: on the basis of Embodiment 1, both ends of the top of the working plate 2 are provided with anti-fall grooves 33, and the bottom of the inner wall of the anti-fall groove 33 is fixedly connected with a magnet block 34, and the anti-fall groove 33 A heat shield 35 is fixedly connected above the magnet block 34 between both sides of the inner wall.

[0033] During use, the magnet block 34 installed on the top of the working board 2 is attracted to the rails, so that the device has an upward pulling force, which prevents the device from falling between the two rails and improves the safety of the device operation. The heat insulation on the top of the magnet block 34 The plate 35 prevents the rail heated by the heating sheet 29 from contacting the magnet block 34 to demagnetize the magnet block 34 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com