A method for removing calcium ions in the extraction and separation process of rare earth sulfate

A separation process, a technology of rare earth sulfate, applied in the direction of improving process efficiency, etc., to achieve the effects of reducing content, reducing the number of box cleaning, and improving the total extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

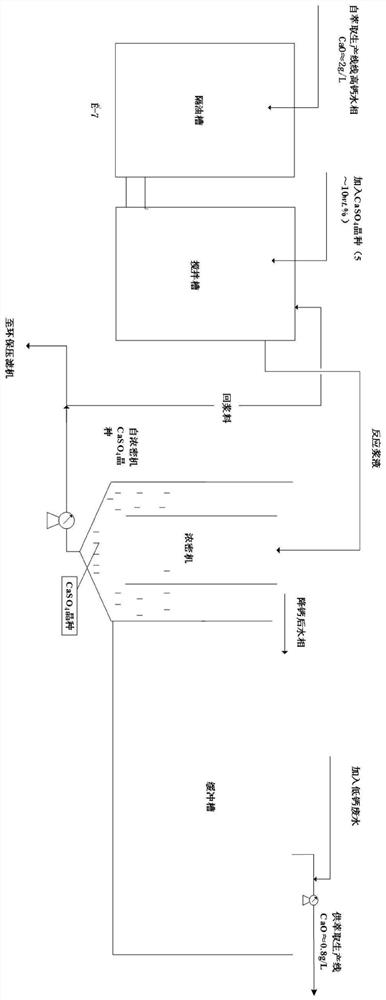

[0039] like figure 1 Be the technical process schematic diagram of the present invention, comprise the following steps:

[0040] Step 1: lead the aqueous phase of the high-calcium sulfate rare earth sulfate solution with a calcium content of 1.89 g / L at the highest concentration point of the extraction production line to the oil separation tank for oil separation. After the oil separation, the petroleum content of the high-calcium water phase is less than 30 ppm;

[0041] Step 2: Lead people 100m into the decalcification tank 3 Add 5000kg of calcium sulfate active seed crystals to the high calcium sulfate rare earth solution after oil separation, start stirring, and react for 60 minutes;

[0042] Step 3: Introduce the slurry in the decalcification tank into a thickener and age for 60 minutes, and analyze the calcium content in the isolated rare earth sulfate solution, and the calcium content is 1.23g / L.

[0043] Step 4: The slurry at the bottom of the thickener is introduced...

Embodiment 2

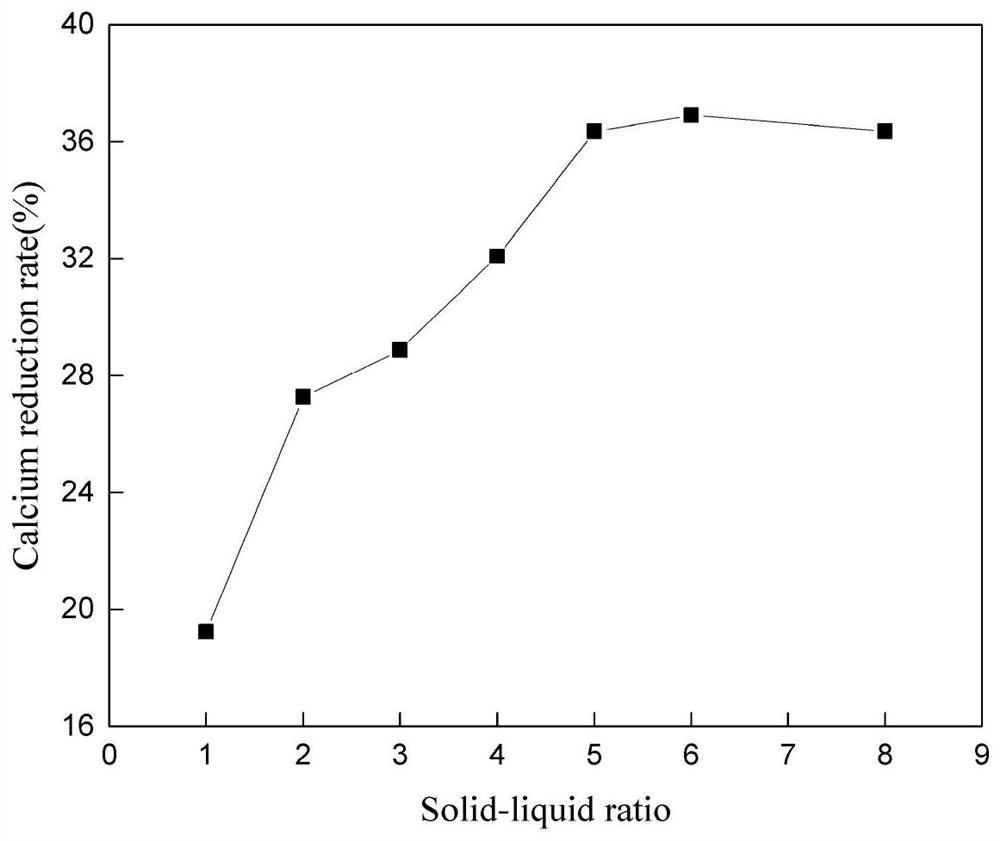

[0047] Influence of the amount of calcium sulfate active seed crystals on the calcium-lowering effect of lanthanum-cerium sulfate solution

[0048] Among them, the lanthanum cerium sulfate solution is produced on-site by the Gansu rare earth production line, the rare earth concentration is 8-10g / L, and the calcium ion concentration is 2-3g / L; the calcium sulfate seed is prepared by the reaction of concentrated sulfuric acid and calcium hydroxide slurry to ensure the pH of the reaction process The value is 6-7.

[0049] Take 500mL of lanthanum cerium sulfate solution and place it in a 1000mL beaker, weigh calcium sulfate seeds in different proportions and add them to the beaker, stir for 1h, let stand for 1h, analyze the supernatant calcium ion concentration (calcium oxide meter), see the experimental results figure 2 ,from figure 2 It can be seen that when calcium sulfate active seeds are added, regardless of the amount added, the concentration of calcium ions in the lantha...

Embodiment 3

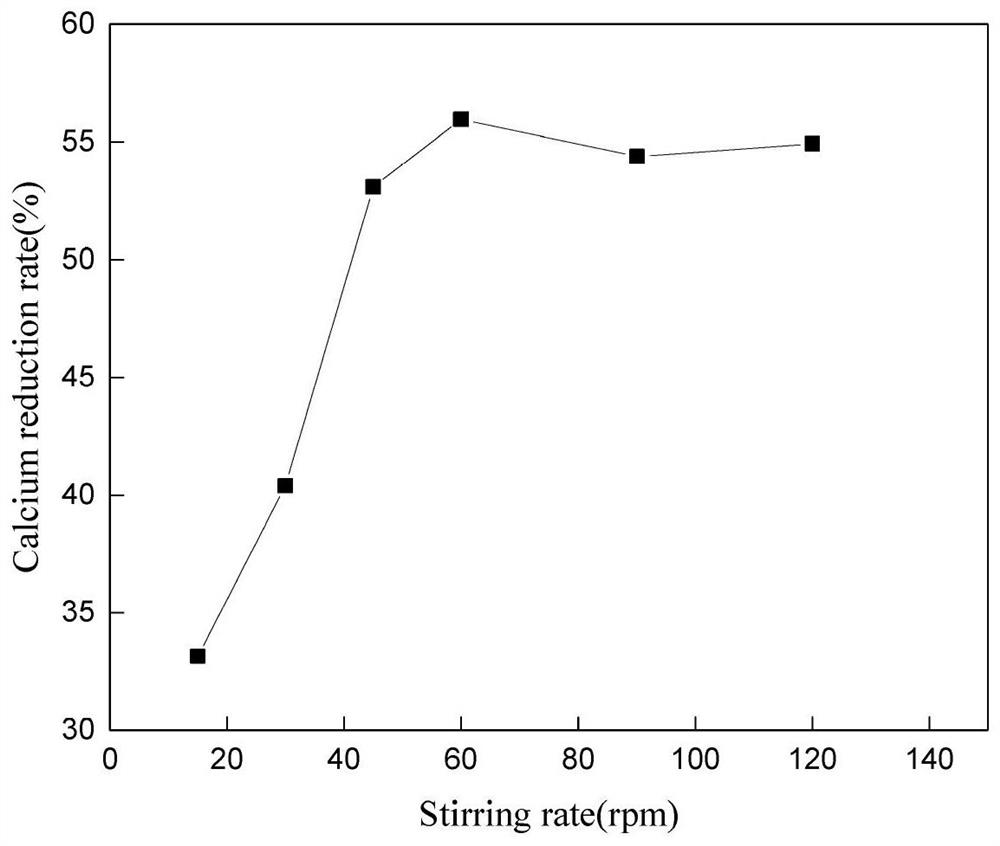

[0051] Effect of Stirring Reaction Time on Calcium Removal Efficiency of Lanthanum-Cerium Sulfate Solution

[0052] Get 500mL of lanthanum cerium sulfate solution and place it in a 1000mL beaker, take by weighing 25g of calcium sulfate seed crystals by solid-to-liquid ratio 5%, add in the beaker, stir for different times, leave standstill for 1h, analyze the supernatant calcium ion concentration (calcium oxide meter), For specific data, see image 3 ,from image 3 It can be seen from the figure that when calcium sulfate seeds are added, the concentration of calcium ions in the lanthanum cerium sulfate solution decreases rapidly (within 1 h) to a certain extent, and remains almost unchanged with the prolongation of stirring time. At the beginning of crystallization, because the system has a large degree of supersaturation, it provides a strong driving force for crystallization, which makes the initial crystallization proceed explosively, as observed in the experiment. decreas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com