External oil separator of horizontal screw machine with oil reservoir

A technology of oil separator and oil storage, which is applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc. It can solve the problems of prolonging cleaning time and use time, difficult cleaning, inconvenient disassembly and assembly, etc., and achieves prolonging cleaning time and Use time, solve the effect of cleaning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

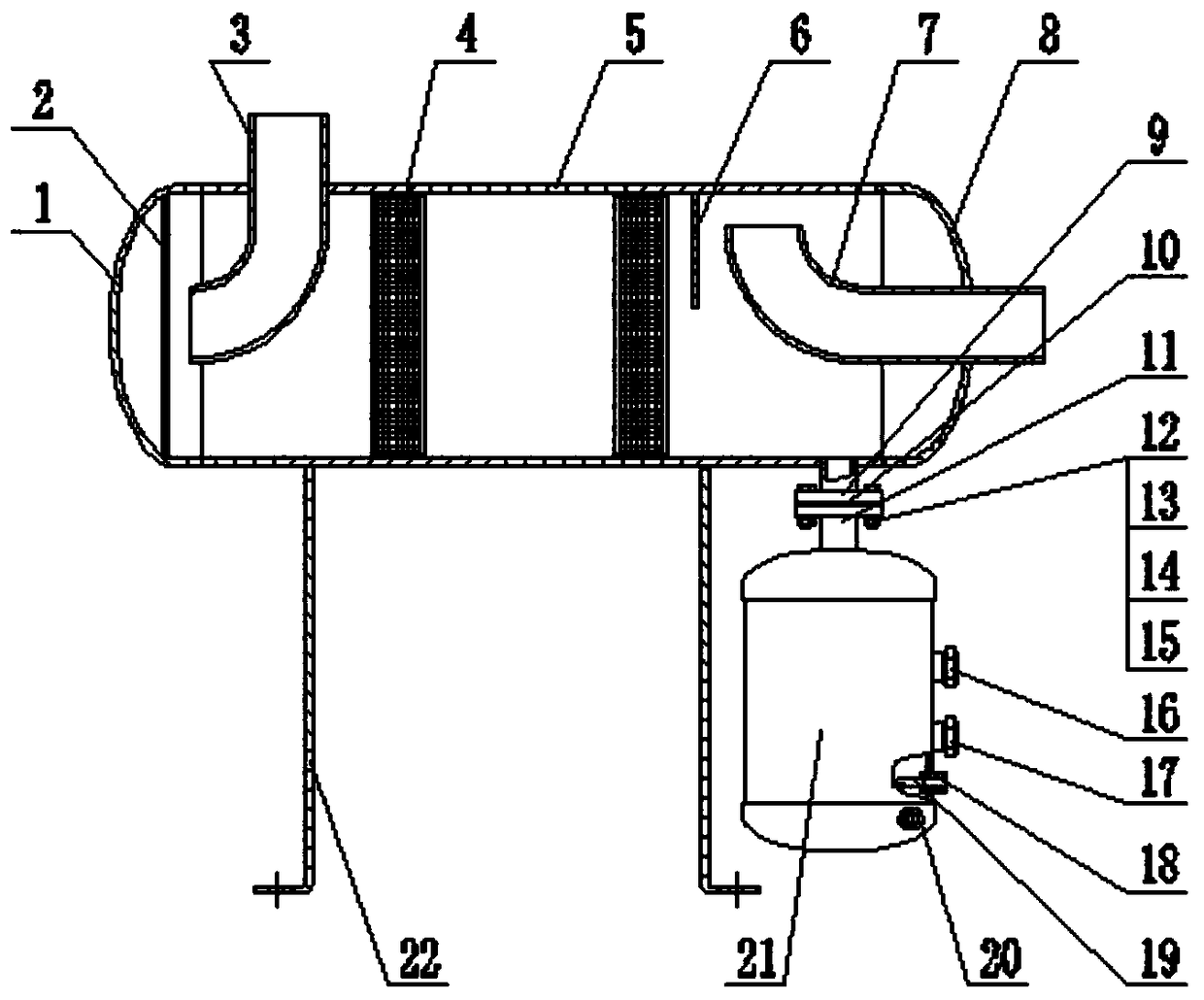

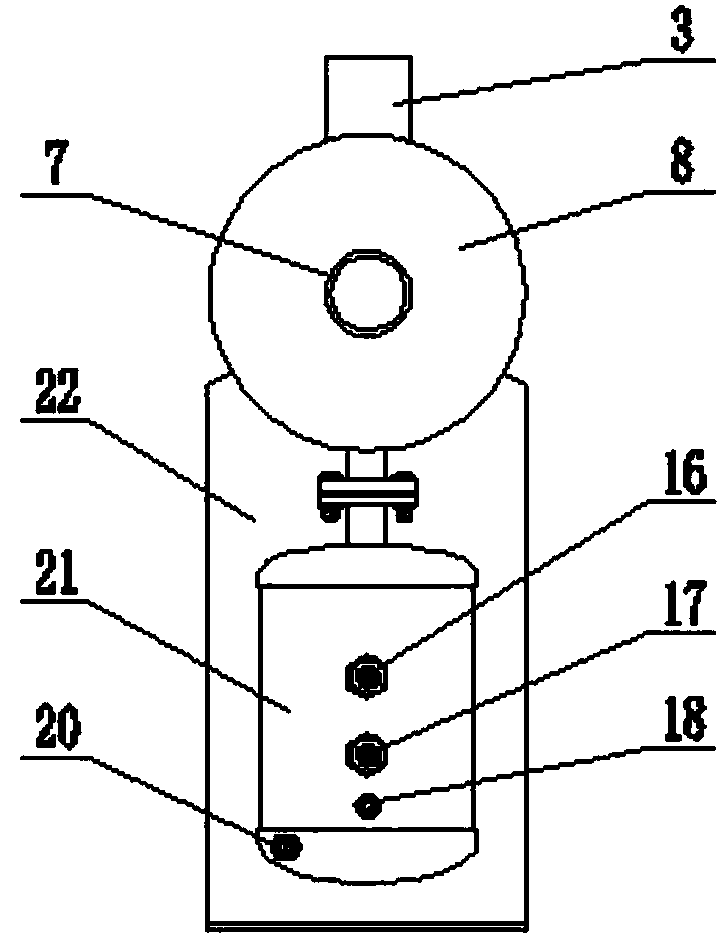

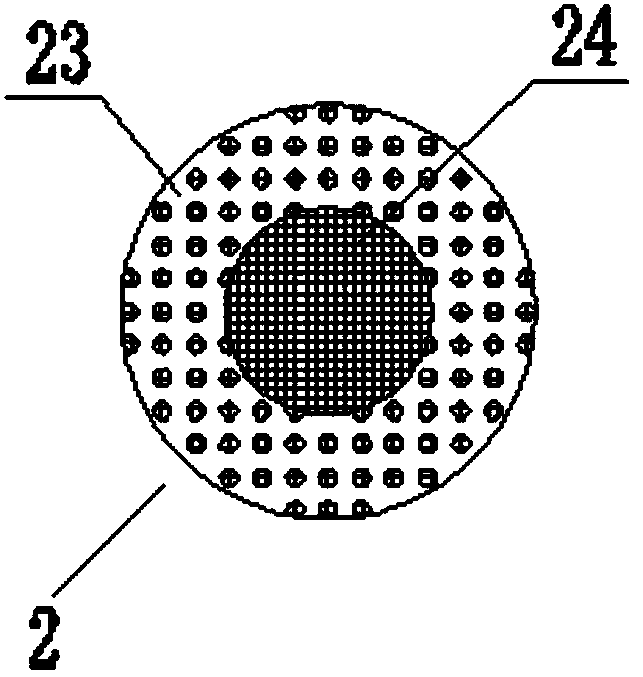

[0018] like Figure 1 ~ Figure 4 As shown, the external oil separator of a horizontal screw machine with an oil reservoir includes an intake baffle assembly 2, a filter screen assembly 4, a cylinder body 5, and an oil reservoir 21. The cylinder body 5 and the left head 1 , the right head 8 is connected into a sealed whole, the air inlet pipe 3 is connected to the inner cavity from the upper left end of the cylinder body 5, the air outlet pipe 7 is in contact with the outside from the right end of the inner cavity of the cylinder body 5, and the end of the inner air inlet pipe 3 is left The intake baffle assembly 2 is arranged on the side, and the filter screen A24 of the baffle assembly 2 is used to absorb the oil in the high-pressure gas entering. The second and third times of oil adsorption greatly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com