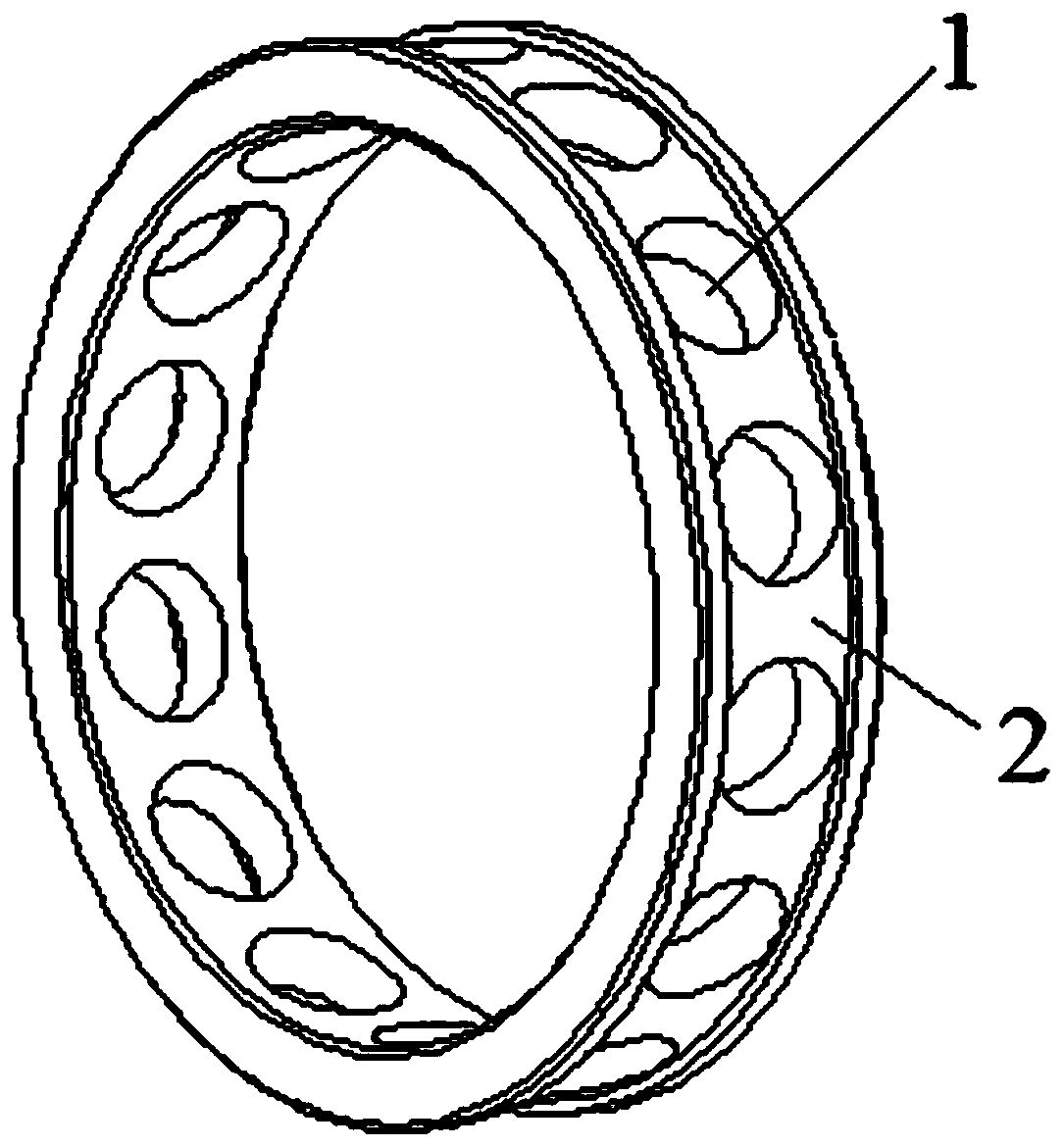

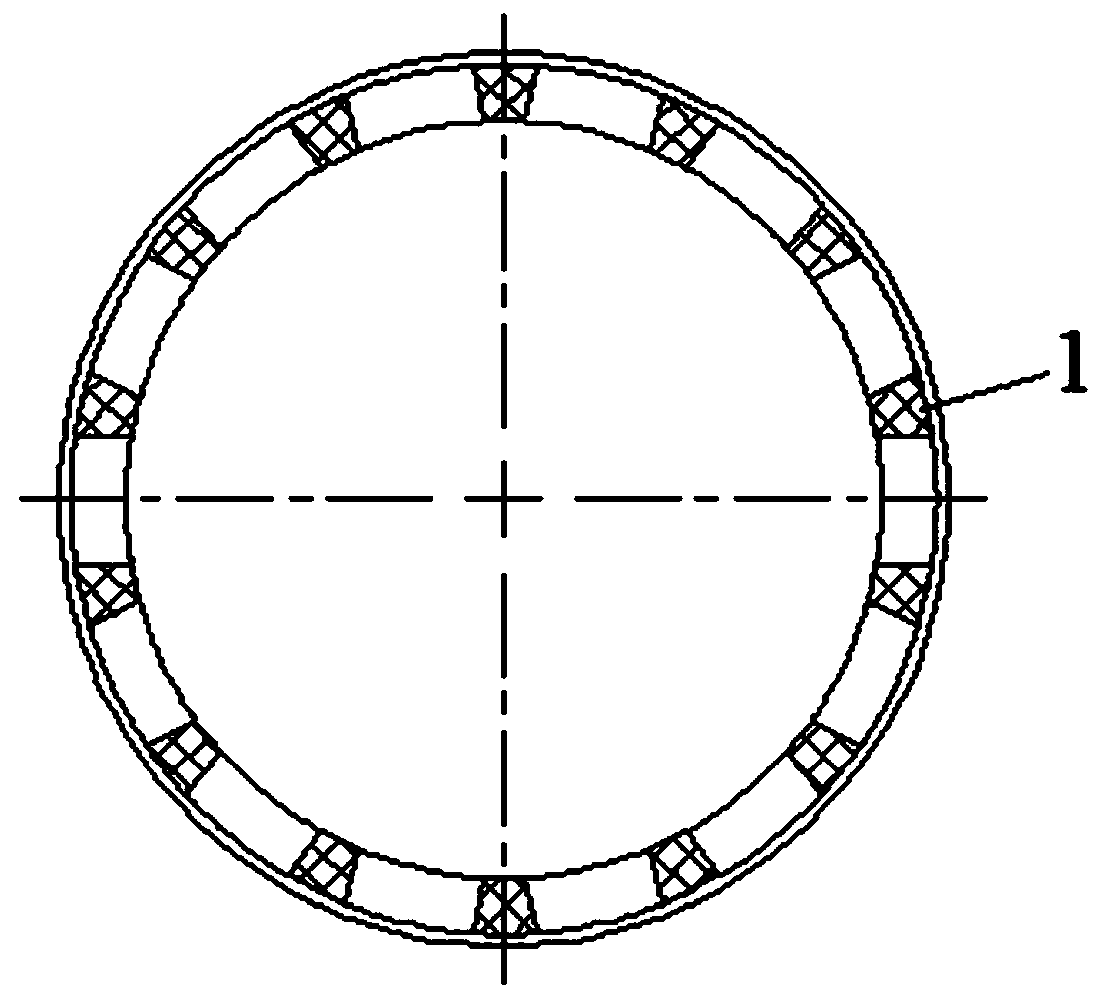

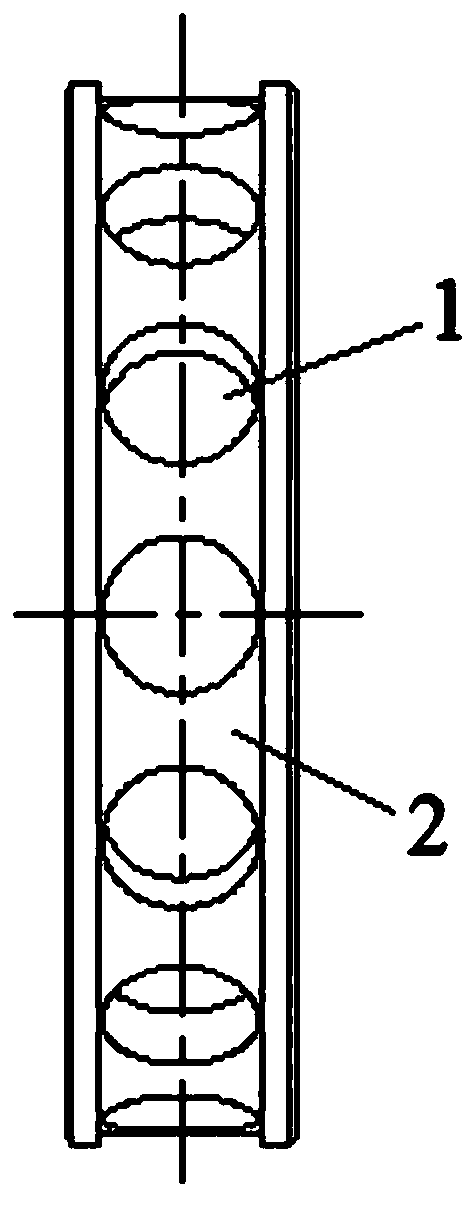

Bearing retainer and preparation method thereof

A bearing cage and cage technology, which is applied to bearing components, shafts and bearings, mechanical equipment and other directions, can solve problems such as bearing jamming, and achieve the effects of high production efficiency, low process cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The bearing cage of this embodiment is formed by injection molding of the following raw materials in parts by weight: 27 parts of carbon fiber with surface oxidation treatment, 12 parts of polybenzimidazole, 60 parts of polyether ether ketone, and 1 part of graphite.

Embodiment 2

[0031] The bearing cage of this embodiment is formed by injection molding of the following raw materials in parts by weight: 24 parts of carbon fiber with surface oxidation treatment, 10 parts of polybenzimidazole, 65 parts of polyether ether ketone, and 1 part of graphite.

Embodiment 3

[0033] The bearing cage of this embodiment is injection-molded from the following raw materials in parts by weight: 21 parts of carbon fiber with surface oxidation treatment, 8 parts of polybenzimidazole, 70 parts of polyether ether ketone, and 1 part of graphite.

[0034] Two, the specific embodiment of the preparation method of the bearing cage of the present invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap