Aggregate bin with drying function

A kind of aggregate bin and functional technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of long-time drying and heating, high energy consumption, etc., achieve full drying, improve efficiency, and extend moving time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

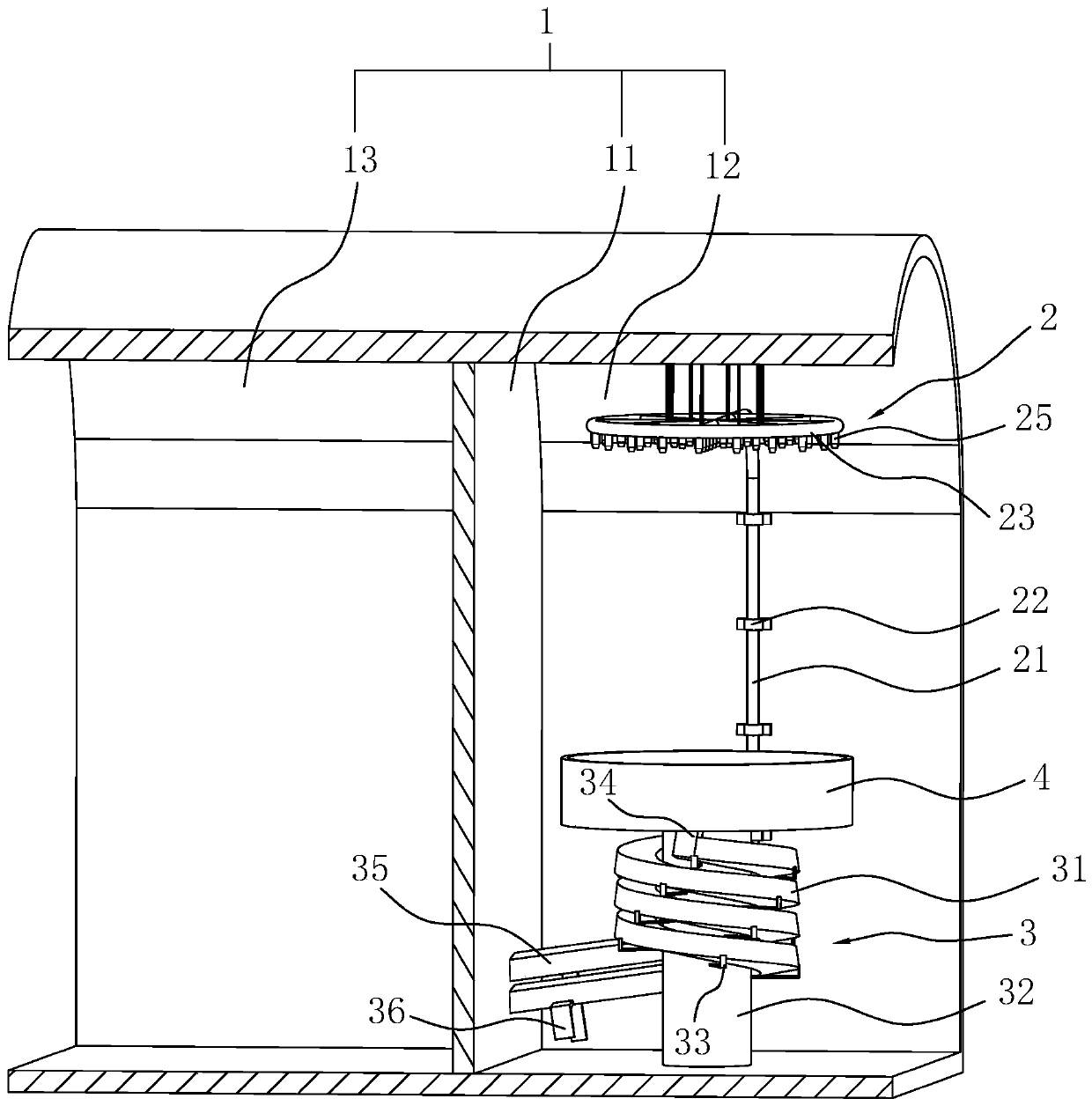

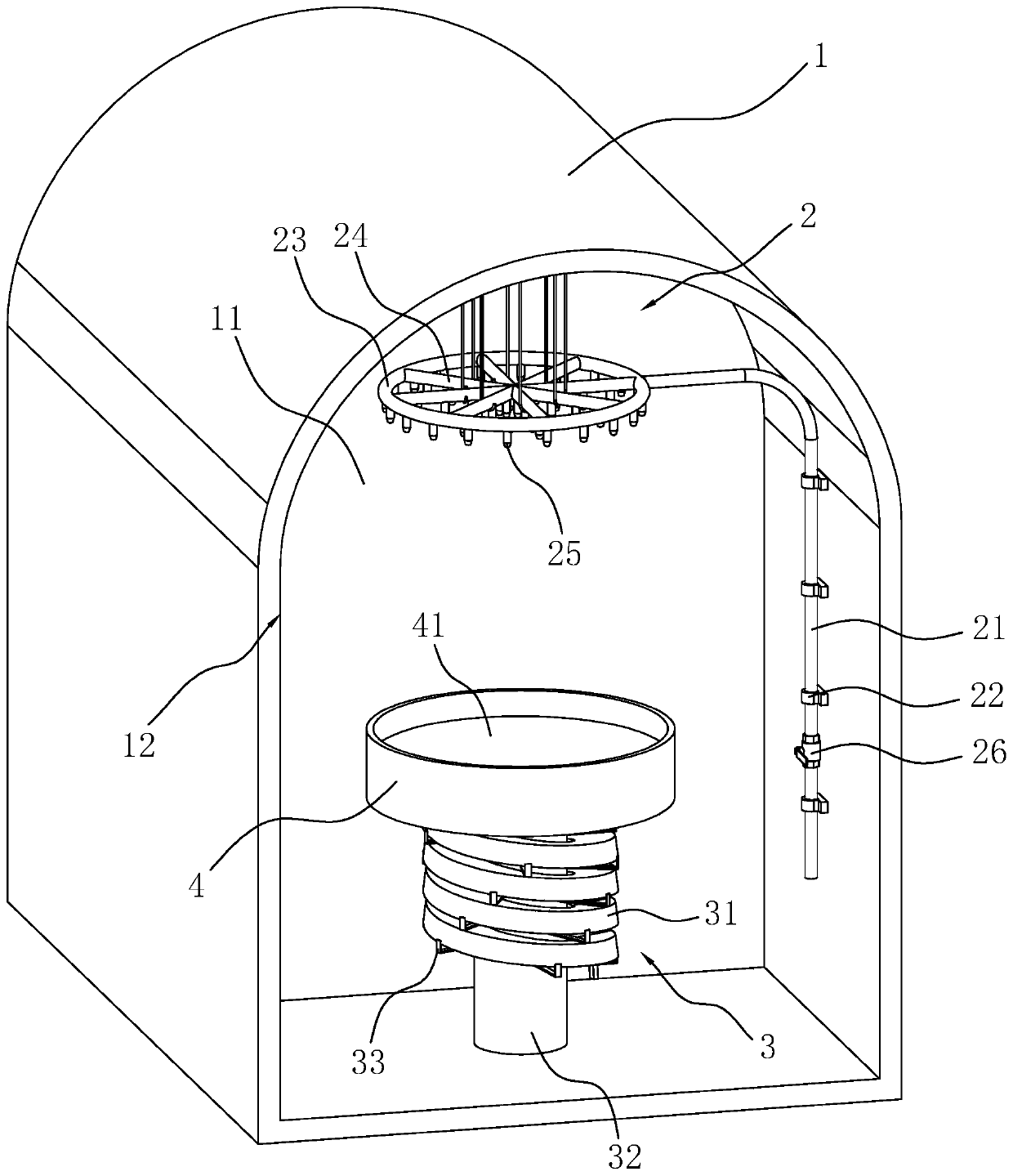

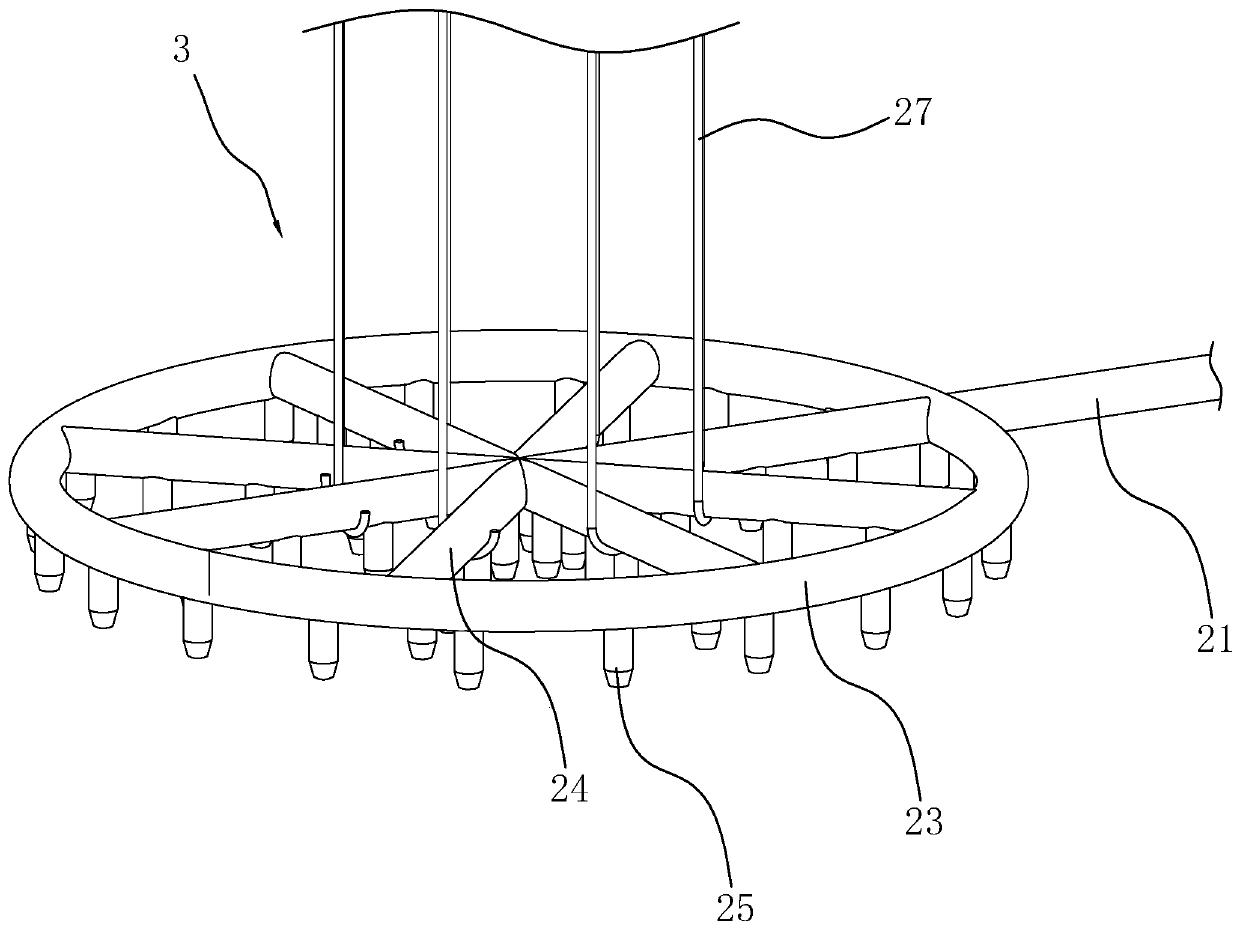

[0034] Such as figure 1 As shown, it is an aggregate silo with a drying function disclosed by the present invention, which includes a silo body 1, and a partition plate 11 is arranged inside the silo body 1, and the partition plate 11 divides the silo body 1 into two parts. An operation bin 12 and a storage bin 13 are formed for both. When the aggregate is stored, the aggregate is first put into the operation bin 12, and a large amount of dust will be generated when the aggregate is put into the operation bin 12, so the top of the operation bin 12 is provided with a spray for processing the dust device 2, and a drying device 3 opposite to the spraying device 2 is provided on the inner bottom of the operation cabin 12. The drying device 3 dries the aggregates after spraying, so as to avoid transporting the aggregates to the next During the process, a long dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com