Steel plate surface defect detection method based on deep learning

A deep learning and defect detection technology, applied in neural learning methods, image data processing, instruments, etc., can solve problems such as difficult to meet production needs, slow speed, poor performance, etc., to achieve the effect of improving accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

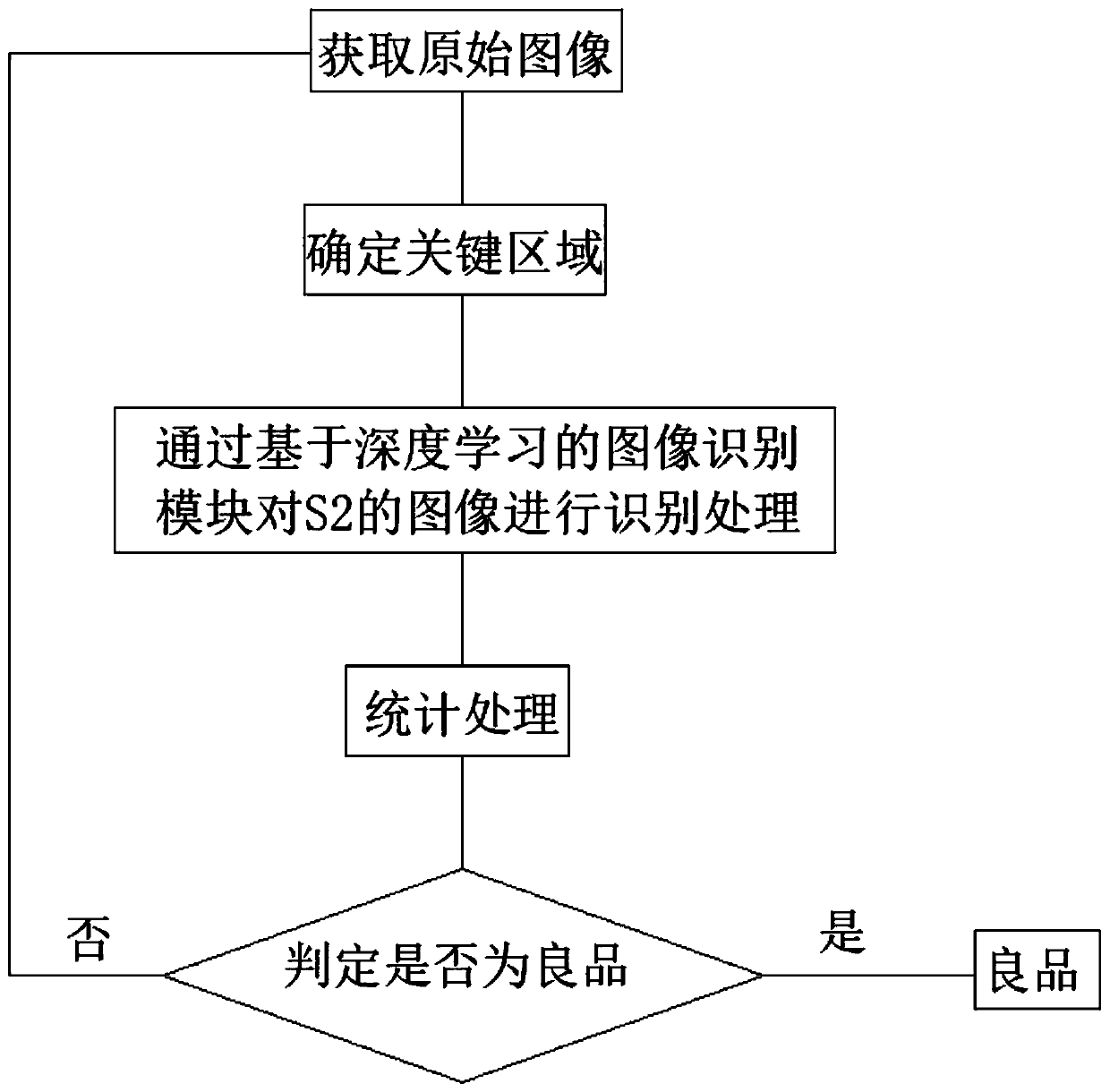

[0017] Specific implementation mode one: as Figure 1 ~ Figure 2 As shown, the present invention discloses a steel plate surface defect detection method based on deep learning, and the method includes the following steps:

[0018] S1: Obtain the original image of the steel plate sample;

[0019] S2: determine the key area of the original image;

[0020] S3: Recognize and process the image of S2 through the image recognition module based on deep learning;

[0021] S4: perform statistical processing on the output result of S3 according to the counting module;

[0022] S5: If the result of S4 is a good product, then the steel plate sample is a good product, otherwise, repeat S1 to S4 to recheck the suspected defective product.

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is a further description of Embodiment 1. The original image of the steel plate sample in S1 is captured by an industrial camera.

specific Embodiment approach 3

[0024] Specific implementation mode three: this implementation mode is a further description of specific implementation mode one. Determining the key region of the original image described in S2 includes the following steps:

[0025] S301: Perform a cutting operation on the original image to obtain multiple slices;

[0026] S302: Input each slice into the image recognition module based on deep learning, perform forward propagation, and obtain the probability that each slice belongs to the key region;

[0027] S303: Determine the slice with the highest probability as the key region of the original image.

[0028] For ease of description, the above three steps are combined for description.

[0029] After the target picture (original image) is determined, a cutting operation is performed on the target picture to obtain multiple slices corresponding to the target picture.

[0030] Specifically, the target image can be cut through a preset sliding window to obtain multiple slices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com