Long and thin rod-shaped electromagnet

A technology of electromagnets and slender rods, which is applied in the direction of electromagnets with armatures, electromagnets, engine components, etc., which can solve the problem of large electromagnets that cannot be installed in small spaces, increase engine fuel consumption and emissions, and fuel injection of fuel injectors. Problems such as slow response speed, to achieve the effect of rapid heat dissipation, increase service life, reduce fuel consumption and pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

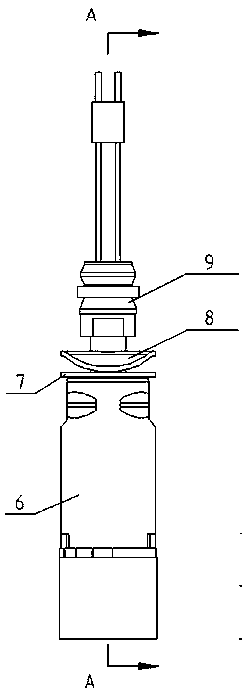

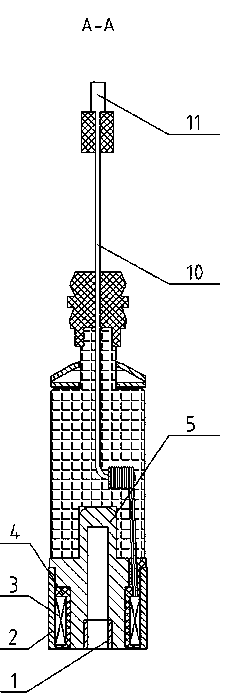

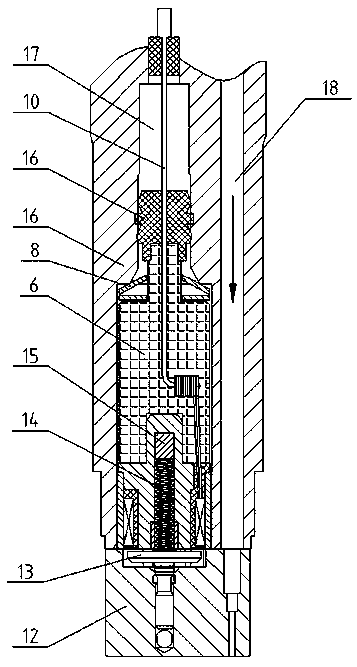

[0024] like figure 1 , figure 2 , image 3 As shown, the slender rod-shaped electromagnet described in this embodiment includes a magnetic isolation ring 1, an outer iron core 2, a coil 3, a bobbin 4, and an inner iron core 5, and is characterized in that: it also includes two terminal posts 10 ; The inner iron core 5 adopts an overall cylindrical stepped shaft shape and a stepped counterbore structure inside, the outer iron core 2 is fastened and installed on the stepped cylindrical surface of the inner iron core 5, and the outer cylindrical surface of the inner iron core 5 is connected to the outer cylindrical surface. The inner cylindrical surface of the iron core 2 is bonded; the coil 3 is installed on the outer cylindrical surface of the small end of the lower part of the inner iron core 5, and is wound on the coil frame 4 in a double-wire parallel winding manner, and is connected with the two terminals 10 The ends are fixed together; the magnetic isolation ring 1 is ...

Embodiment 2

[0029] On the basis of above-mentioned embodiment, propose embodiment 2, as figure 1 As shown, it is characterized in that: the slender rod-shaped electromagnet also includes a flat gasket 7 and a disc spring pad 8; the flat gasket 7 and the disc spring pad 8 are installed on the upper thin shaft of the plastic sealing post 6 part.

Embodiment 3

[0031] On the basis of above-mentioned embodiment, propose embodiment 3, as figure 2 As shown, it is characterized in that: the top of the coil 3 and the end face of the electromagnet are shallow and deep installation structures.

[0032] During implementation, the coil skeleton 4 at the top of the coil 3 is very thin, and the end of the coil 3 is very close to the end face of the electromagnet, so that a shallow and deep installation structure can be formed.

[0033] In this embodiment, the shallow and deep installation structure with the end of the coil 3 very close to the end face of the electromagnet can increase the electromagnetic force, further improve the response speed, and at the same time facilitate the rapid heat dissipation of the coil 3 and improve the service life of the electromagnet

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com