A preparation method of lithium battery electrodes based on laser shock technology

A laser shock, lithium battery technology, applied in battery electrodes, electrode manufacturing, laser welding equipment and other directions, can solve problems such as poor click performance of lithium batteries, and achieve the effect of increasing specific surface area, reducing spacing, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

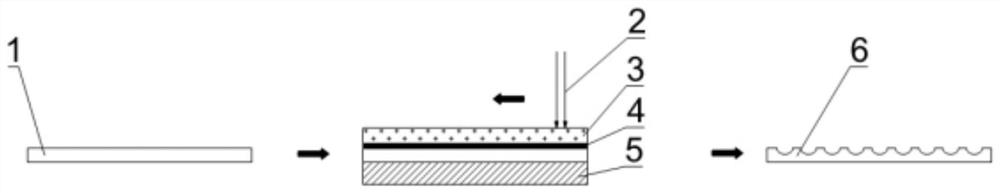

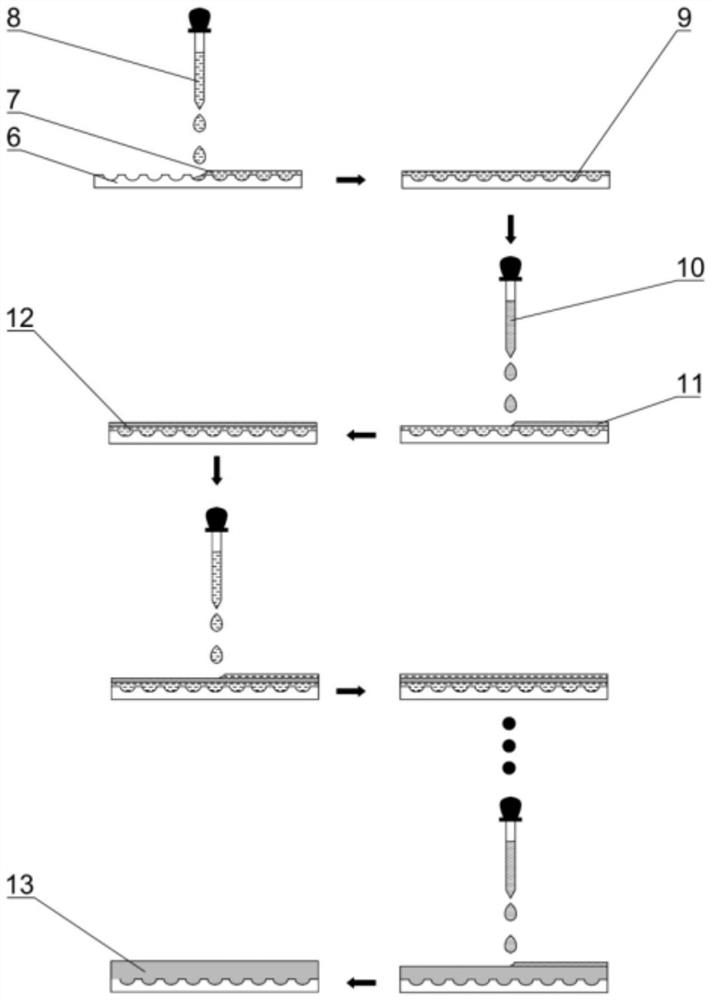

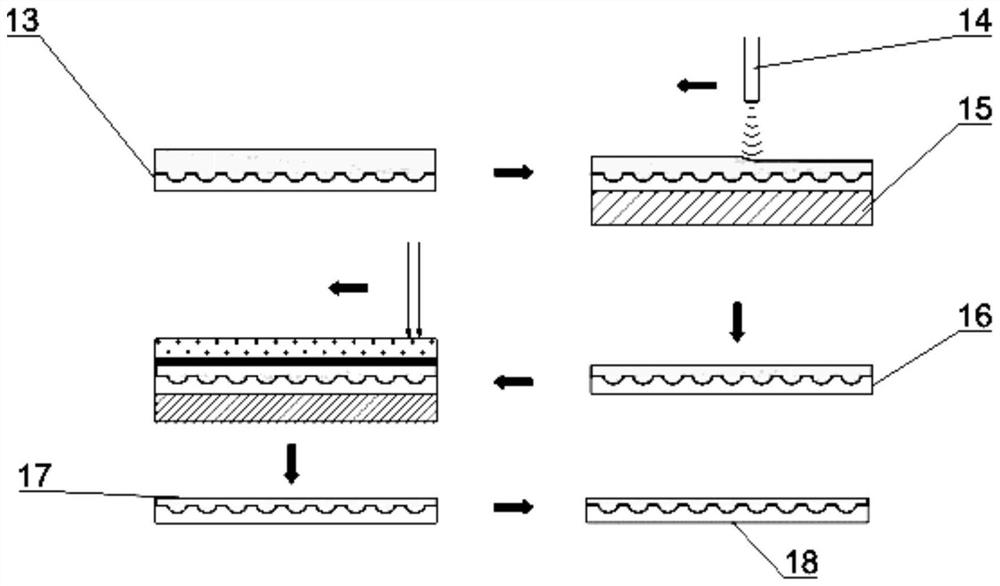

[0037] A preparation method of lithium battery electrodes based on laser shock technology:

[0038] Step 1: Lay a layer of absorbent layer 4 (black polytetrafluoroethylene tape) on the surface of the clean copper foil 1; lay a layer of constrained layer 3 (water) on the top of the absorbent layer 4; lay the absorbent layer 4 and the constrained layer 3 is fixed on the fixture 5 of the six-axis robot 21; according to the production plan, determine the various parameters of the laser shock; use the laser 24 (Q-switched Nd:YAG laser) to output the laser beam 5, and the laser first changes through the optical device 22 transmission direction and focusing, and then penetrate the constrained layer 3 and be absorbed by the absorbing layer 4 to generate a plasma explosion to form a shock wave, which impacts on the copper foil 1 to form a micro-pit array, and obtains the pretreated copper foil 6 (such asfigure 1 As shown, the arrow above the constraint layer 3 in the figure is the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com