Galvanic pile heat dissipation system and method for hydrogen energy automobile

A technology of a heat dissipation system and a heat dissipation method is applied in the field of the stack heat dissipation system of a hydrogen energy vehicle, and can solve the problems of unfavorable on-board fuel cell hydrogen use efficiency, low radiator efficiency, inability to solve and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

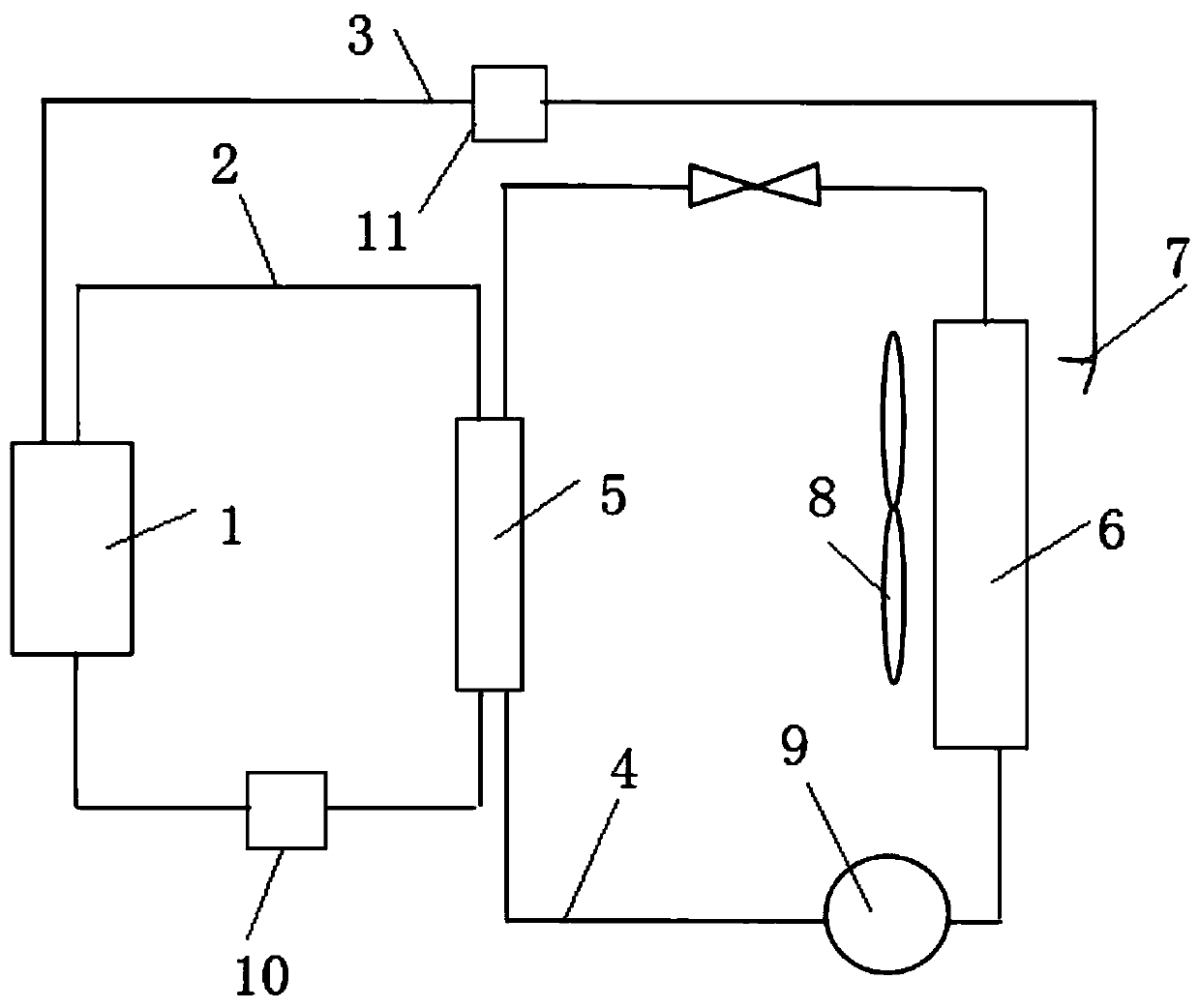

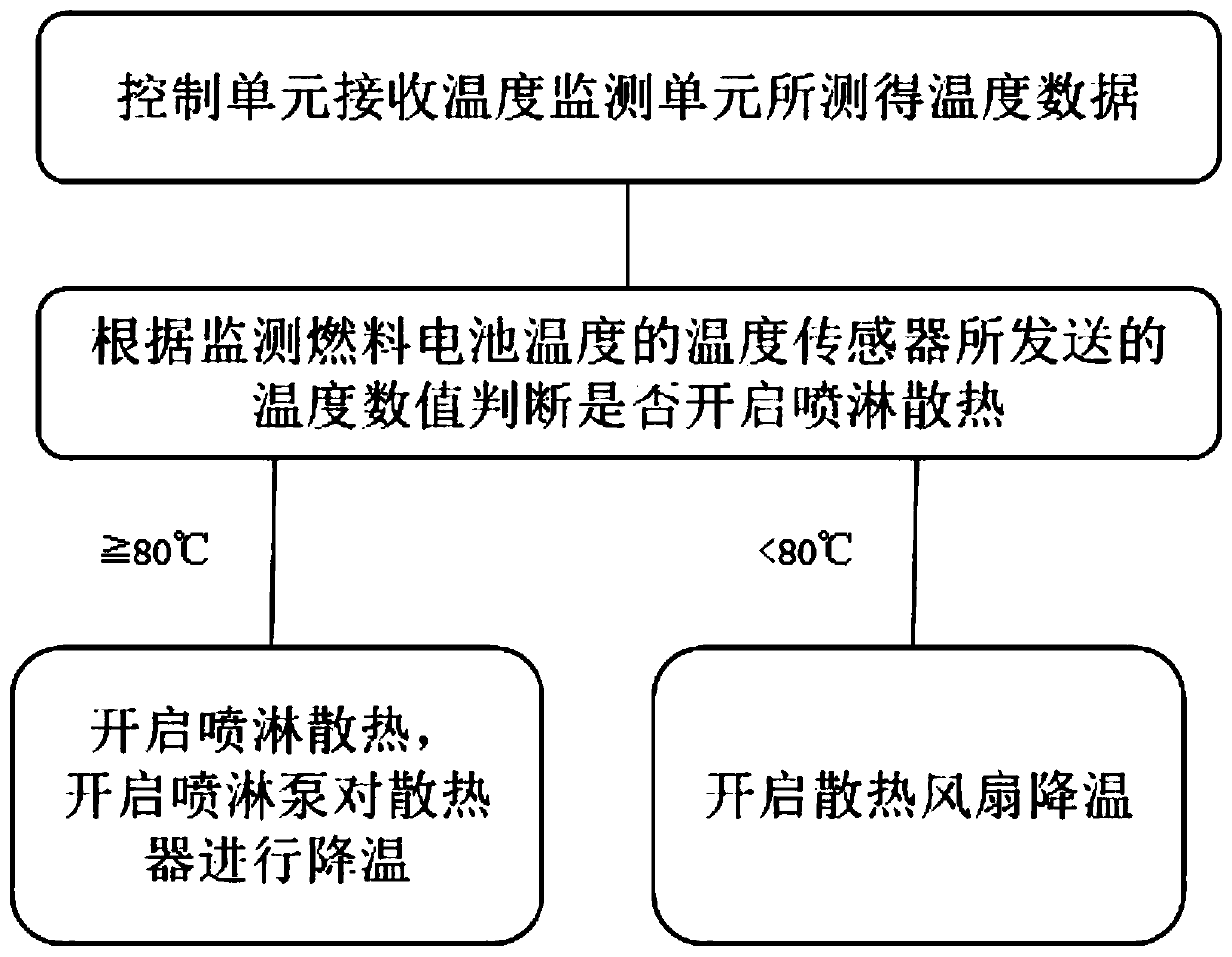

[0026] Example 1: See figure 1 As shown, the present invention is a stack heat dissipation system for a hydrogen energy vehicle, including a fuel cell 1 installed in the vehicle. The fuel cell 1 for the vehicle uses a heat exchange pipeline system and a heat dissipation pipeline when cooling down. system, wherein the heat dissipation pipeline system can be carried out by means of heat dissipation fan 8 and / or spray water cooling.

[0027] Specifically, the heat exchange pipeline system includes a liquid cooling pipeline 2 and a heat exchanger 5, wherein the liquid cooling pipeline 2 is equipped with a cooling night circulation pump 10 for cooling liquid in the liquid cooling pipeline 2, and the liquid cooling pipeline 2 is A closed-loop pipeline passing through the heat exchanger 5 and the fuel cell 1, wherein the heat exchanger 5 can be a plate heat exchanger;

[0028] When the cooling liquid transports the heat of the fuel cell 1 to the heat exchanger 5, the heat exchanger ...

Embodiment 2

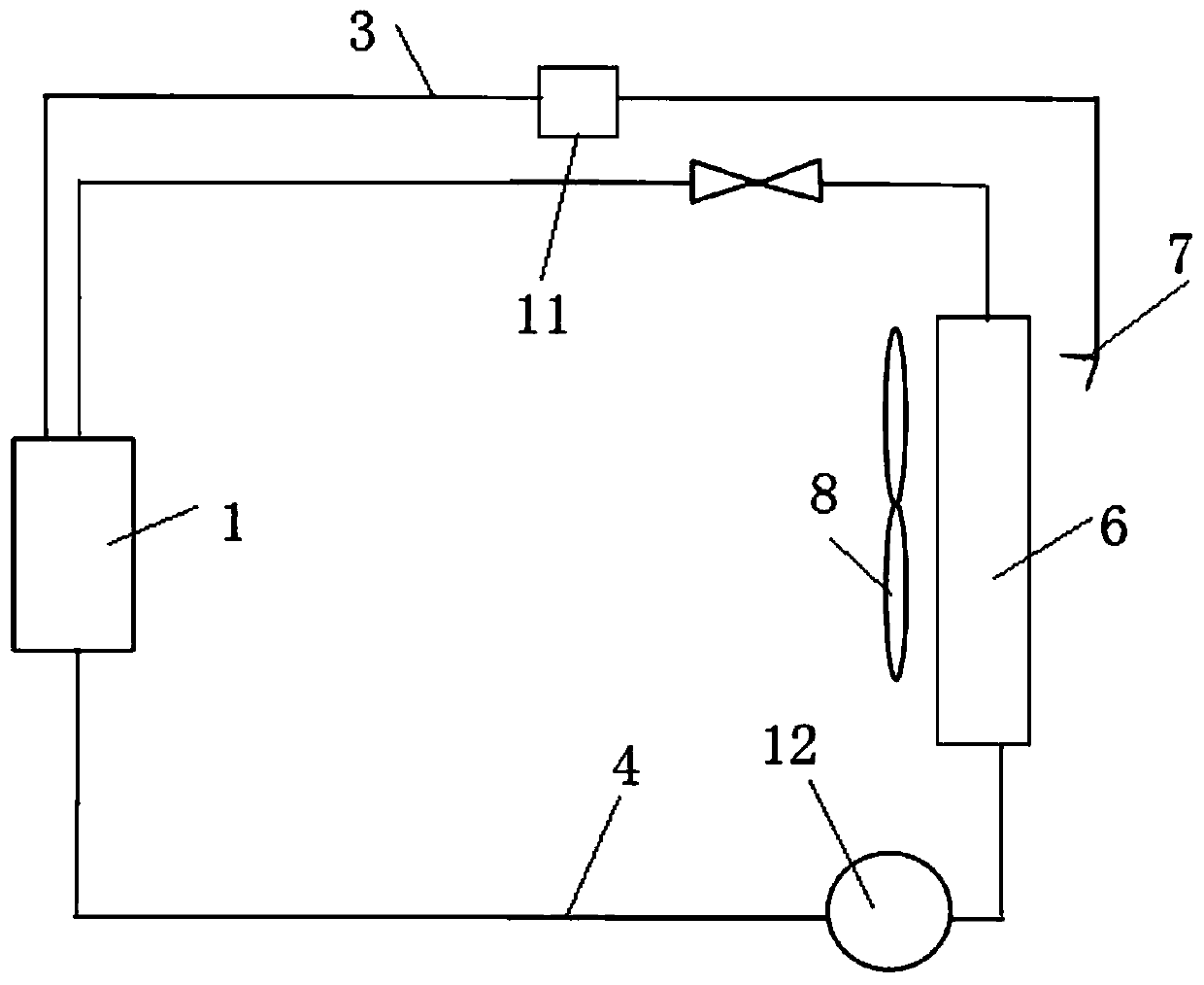

[0047] Other specific such as figure 2 As shown, this heat exchange method is to remove the heat exchange pipeline system in Embodiment 1, directly connect the refrigerant pipeline 4 on the heat dissipation pipeline system to the fuel cell 1, and remove the heat transfer device 9 and replace it with The circulation pump is used to dissipate heat from the fuel cell 1 . The water generated by the fuel cell is directly sprayed onto the radiator 6 and cooperates with the fan 8 to dissipate heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com