Parallel automatic famous high-quality tea picking robot

A technology for picking robots and high-quality tea, which is applied to picking machines, manipulators, harvesters, etc., can solve the problems of high labor costs, untimely picking of fresh leaves, weak selection or selection ability, etc., to reduce labor intensity and broaden the market Application prospects, the effect of low damage to fresh leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

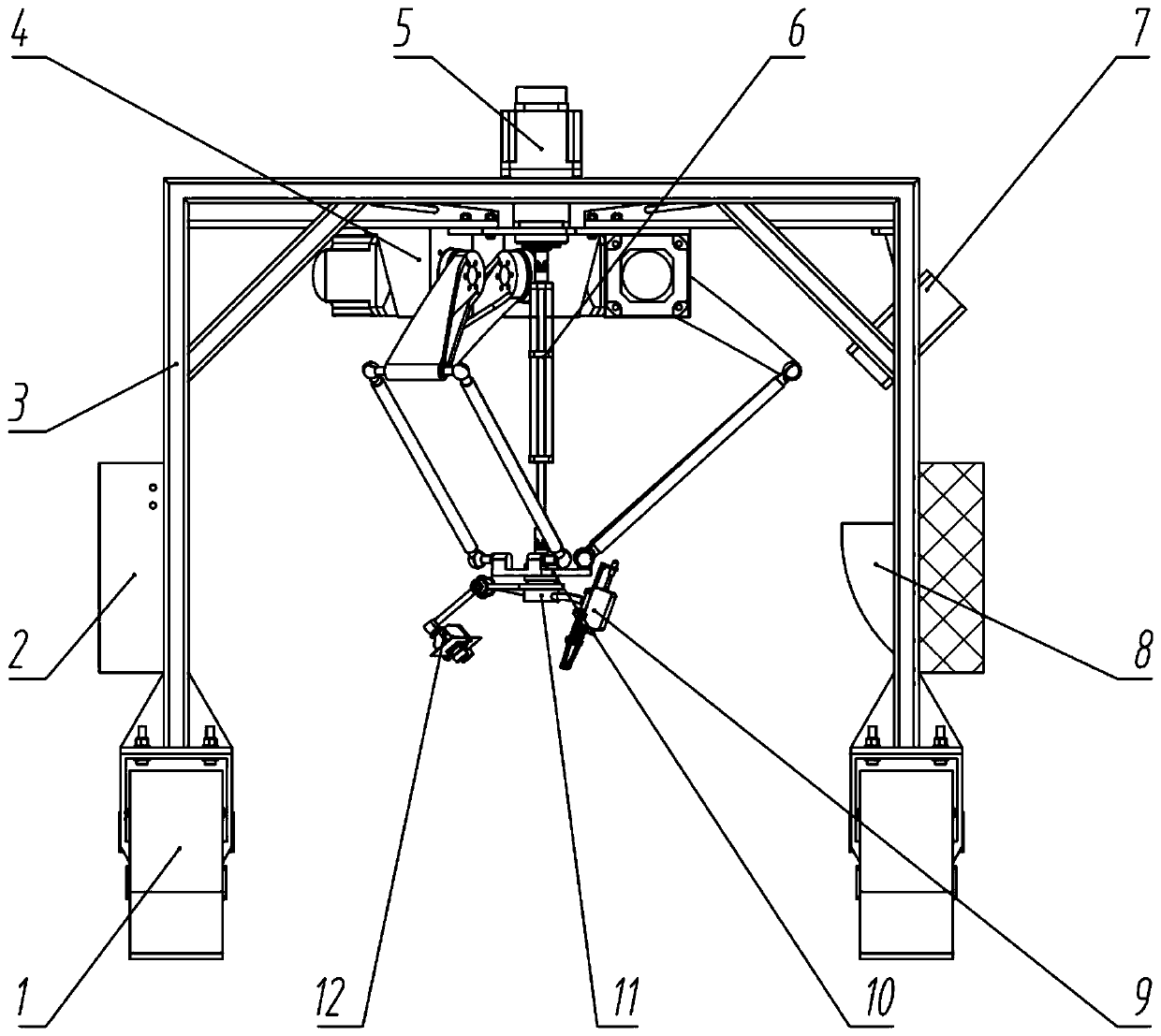

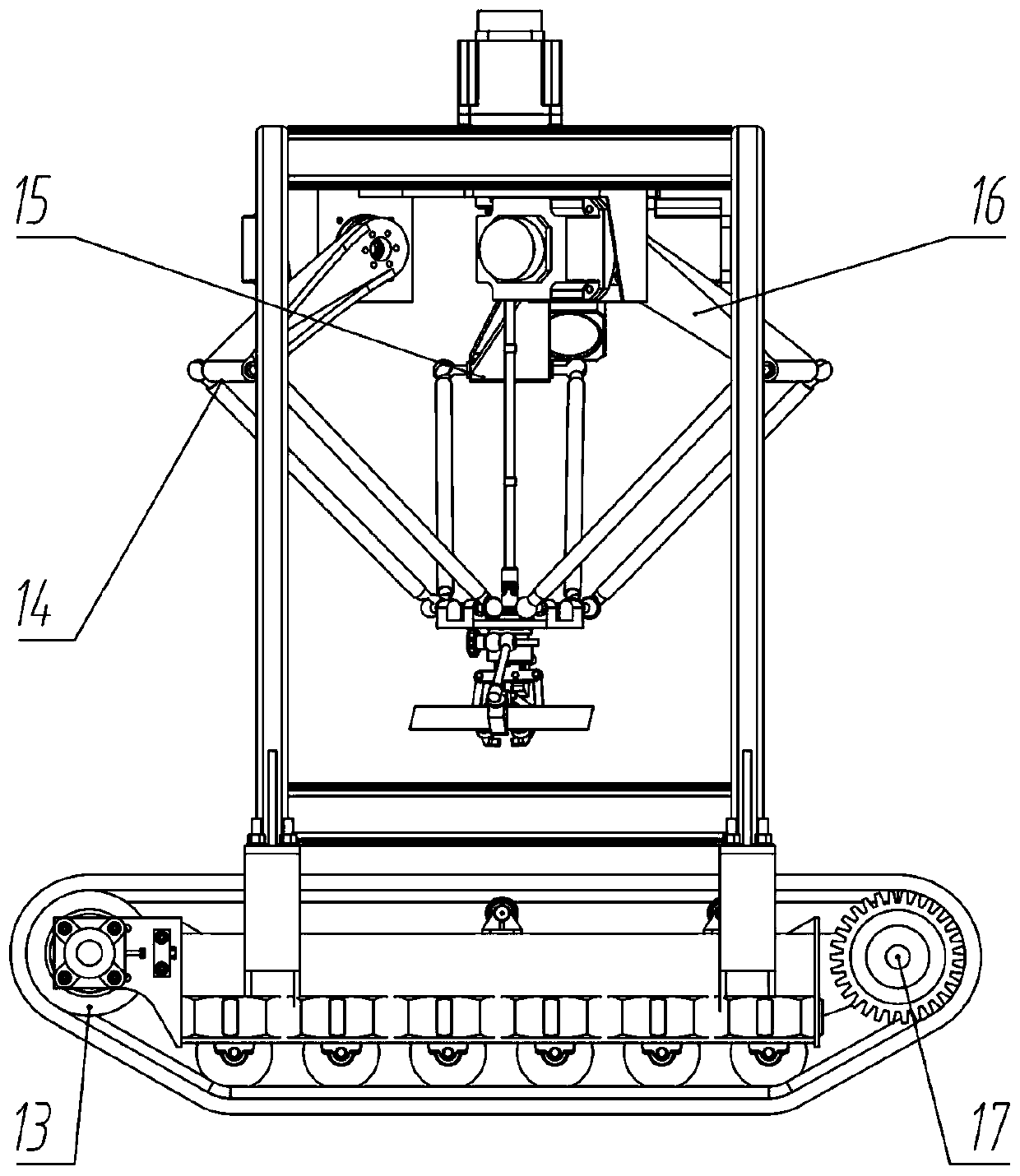

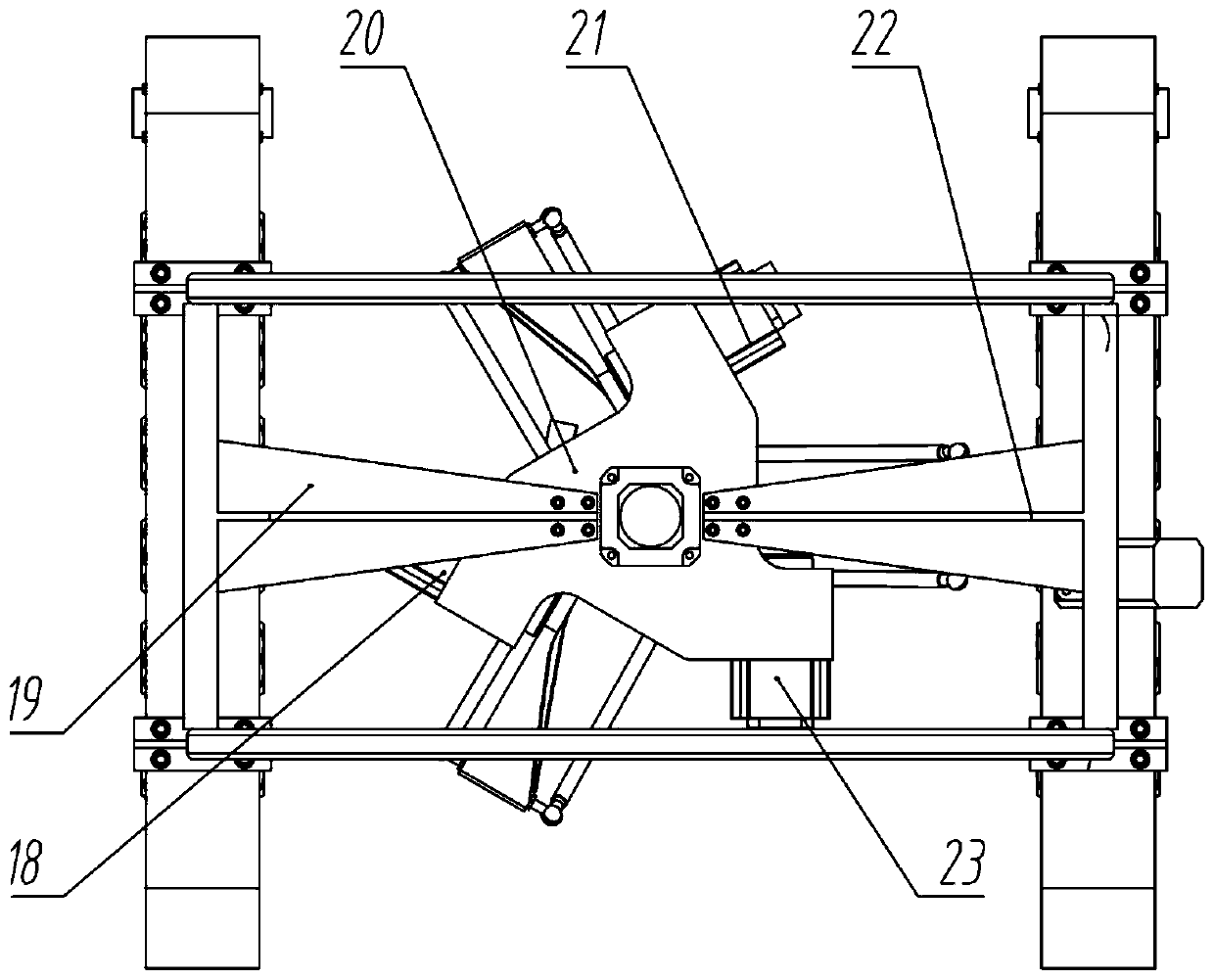

[0020] Such as Figure 1-Figure 5 As shown, the traveling mechanism (1) carries the equipment and walks in the tea garden under the control of the main control system (2), and stops when it reaches the initial section of the designated tea picking ridge. The parallel mechanical arm (4) performs the initial zero adjustment procedure, specifically, under the control of the main control system (2), the branch chain rotating motor A (18) rotates to drive the branch chain A (16) to return to the zero point of the setting mechanism, and the branch chain rotating motor The rotation of B(21) drives the branch chain B(14) to return to the zero point of the setting mechanism, the rotation of the branch chain rotating motor C(23) drives the branch chain C(15) to return to the zero point of the setting mechanism, and the rotation of the terminal rotating motor (5) drives the terminal to rotate Platform (11) returns to setting mechanism zero. At this time, the global positioning camera (7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com