A single wedge locking self-propelled pushing device and method

The technology of locking device and pushing device is applied in the direction of hoisting device, hoisting device, processing of building materials, etc., which can solve the problems of increased workload and low pushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

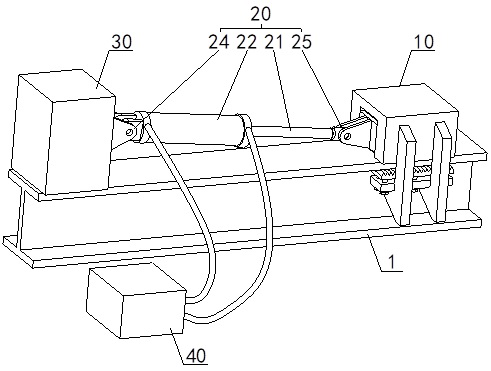

[0038] This embodiment takes the jacking construction of a large steel structure as an example. Figure 1 to Figure 5 The single-wedge locking self-propelled pushing device of the present invention is described, which includes: a single-wedge locking device 10 and a pushing seat 30 arranged at intervals, and a push-off seat arranged between the single-wedge locking device 10 and the pushing seat 30 Push the oil cylinder 20, and the push oil cylinder 20 is connected with the oil circuit of the control center 40;

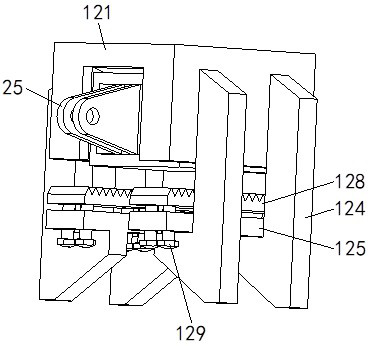

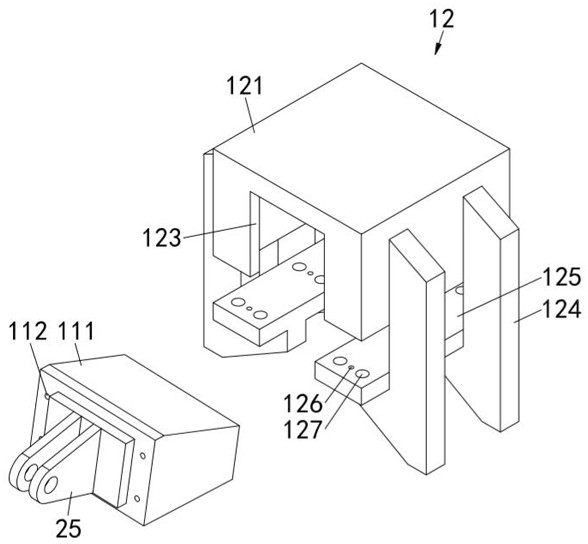

[0039] The single wedge locking device 10 includes an oil cylinder reaction frame 12 and a wedge-shaped slider 111. The oil cylinder reaction frame 12 is clamped and fixed on the rail 1. The oil cylinder reaction frame 12 is provided with a wedge-shaped groove 122 whose bottom surface communicates with the rail 1 along its length direction. , the length direction of the cylinder reaction frame 12 is consistent with the extending direction of the rail 1, the wedge-shap...

Embodiment 2

[0050] combine Figure 1 to Figure 5 Illustrate the self-propelled pushing method of the present invention, concrete steps are as follows:

[0051] S1: if figure 1 As shown, two single-wedge locking self-propelled pushing devices are respectively arranged directly above the track 1 along the center line of the parallel double-track 1, and the single-wedge locking self-propelled pushing devices include single-wedge locking devices arranged at intervals 10 and the push seat 30, and the push cylinder 20 connected between the two, the single wedge locking device 10 includes the cylinder reaction force frame 12 and the wedge-shaped slider 111, and the oil cylinder reaction force frame 12 is clamped and fixed on the track 1, The cylinder reaction force frame 12 is provided with a wedge-shaped groove 122 whose bottom surface communicates with the track along its length direction. The wedge-shaped slider 111 is embedded in the wedge-shaped groove 122 and is hinged with one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com