Zero-discharge recycling treatment process for wastewater and waste liquid on surface chemical treatment process line

A technology of surface chemical treatment and treatment process, which is applied in the field of waste water and waste liquid recycling treatment process, can solve the problems of inability to achieve zero discharge, supporting use, and classification treatment of waste water and waste liquid, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

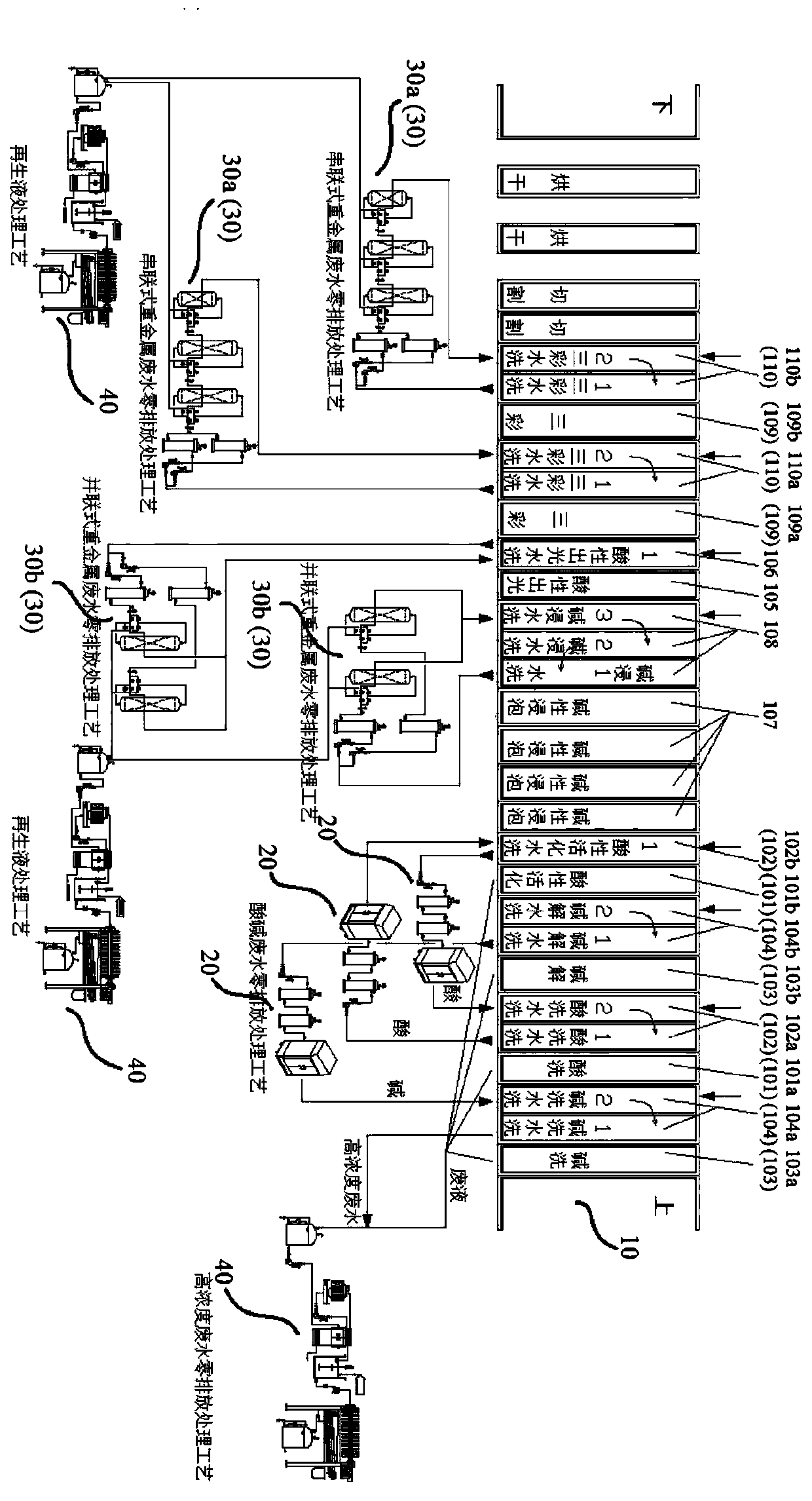

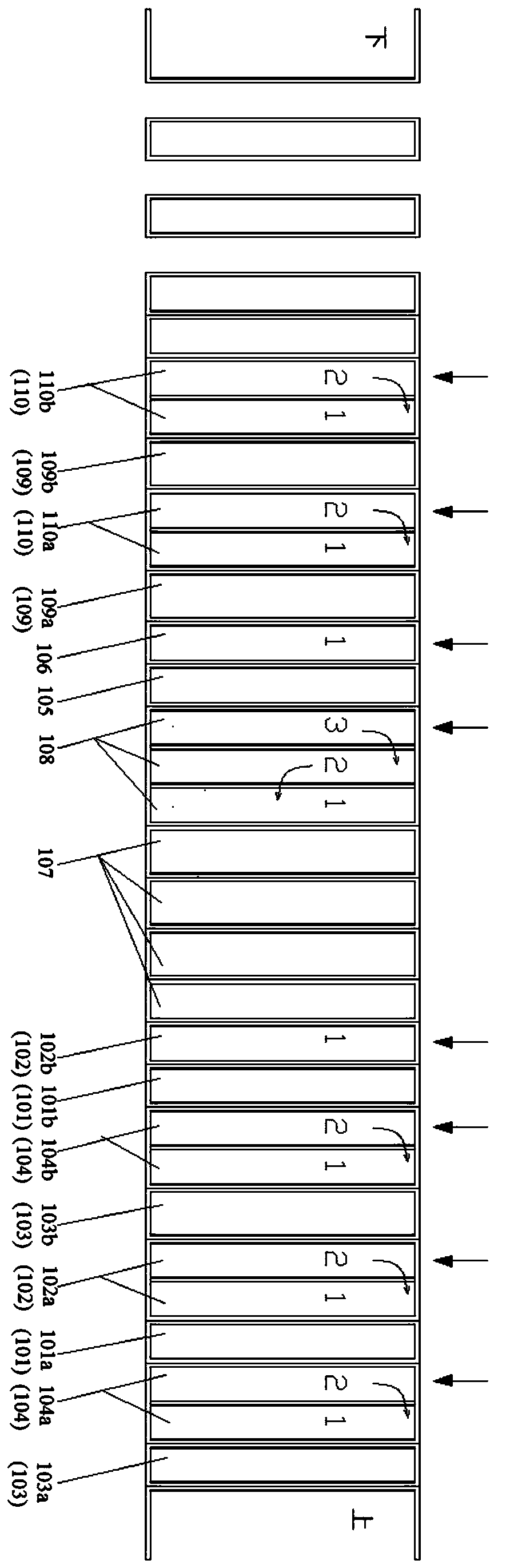

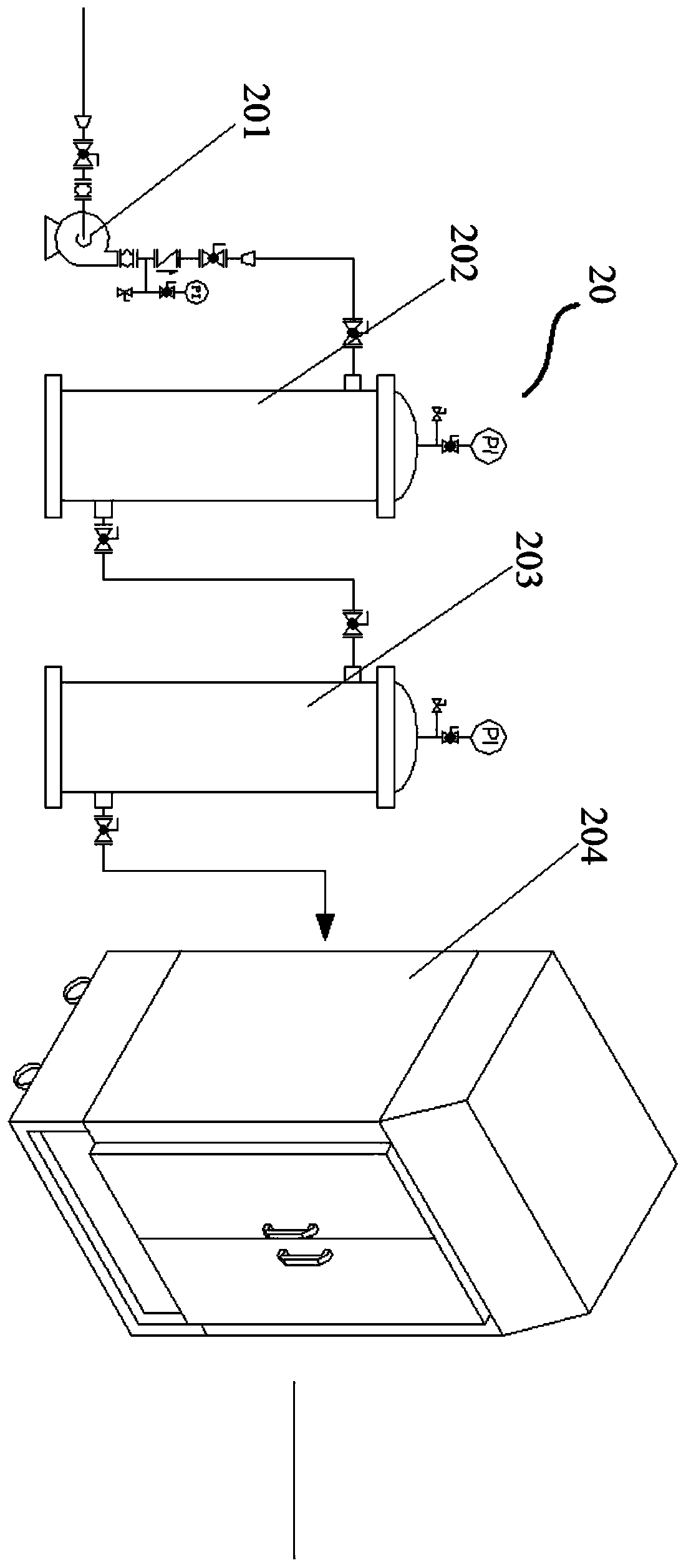

[0056] The present invention introduces in detail a treatment process for zero-discharge recycling of waste water and waste liquid on the surface chemical treatment process line. The treatment process includes the following steps:

[0057] S1, the waste water produced by the acid washing tank located downstream of the process is treated by the acid-base wastewater zero discharge treatment device, and then enters the acid wash tank located upstream of the process for reuse; the said upstream of the process The wastewater generated in the same ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com