A kind of pure inorganic water-based topcoat, its preparation method and pure inorganic water-based architectural coating

A water-based topcoat and inorganic technology, applied in fire-resistant coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of poor appearance, easy powder drop and scrub resistance, poor appearance of pure inorganic water-based architectural coatings, etc. Uniform drying, excellent inorganic bonding properties, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

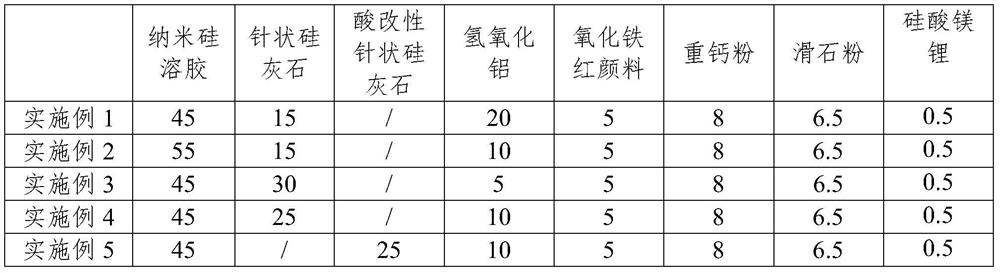

[0040] Embodiment 1~Example 5 provide a kind of pure inorganic water-based finish paint respectively, and concrete components are as shown in table 1:

[0041] Components and weight proportions of the pure inorganic water-based topcoat of table 1 embodiment 1~embodiment 5

[0042]

[0043] The preparation method of the pure inorganic water-based finish paint of embodiment 1~embodiment 5 all comprises the steps:

[0044] (1) Weigh each raw material in proportion, add acicular wollastonite powder and iron oxide red pigment into the nano-silica sol, soak for 2 hours, then disperse at 6000r / min for 10 minutes to obtain the first dispersion;

[0045] (2) Add aluminum hydroxide, heavy calcium powder and talcum powder to the first dispersion obtained in step (1), soak for 1 hour, then disperse for 20 minutes under the condition of 3000 r / min, until the fineness is less than 50 μm, and obtain the second Dispersion liquid; control the system temperature below 50°C during the proces...

Embodiment 6~ Embodiment 10

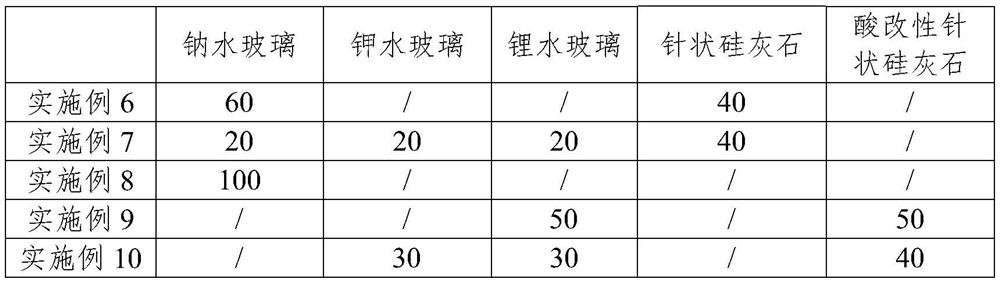

[0048] Embodiment 6~embodiment 10 provide a kind of pure inorganic water-based primer respectively, and concrete components are as shown in table 2:

[0049] Component and weight proportion of the pure inorganic water-based primer of table 2 embodiment 6~embodiment 10

[0050]

[0051] The preparation method of the pure inorganic water-based primer of embodiment 6~embodiment 10 all comprises the following steps: adding acicular wollastonite powder into water glass and soaking for 2h, then dispersing under 6000r / min condition for 10min, after dispersing evenly, obtains pure inorganic Water-based primer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com