Recoverable anchor rod and construction method thereof

A construction method and bolt technology, applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve the problems of construction impact, construction machinery damage, anchor pieces left underground, etc., and achieve the effect of avoiding equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

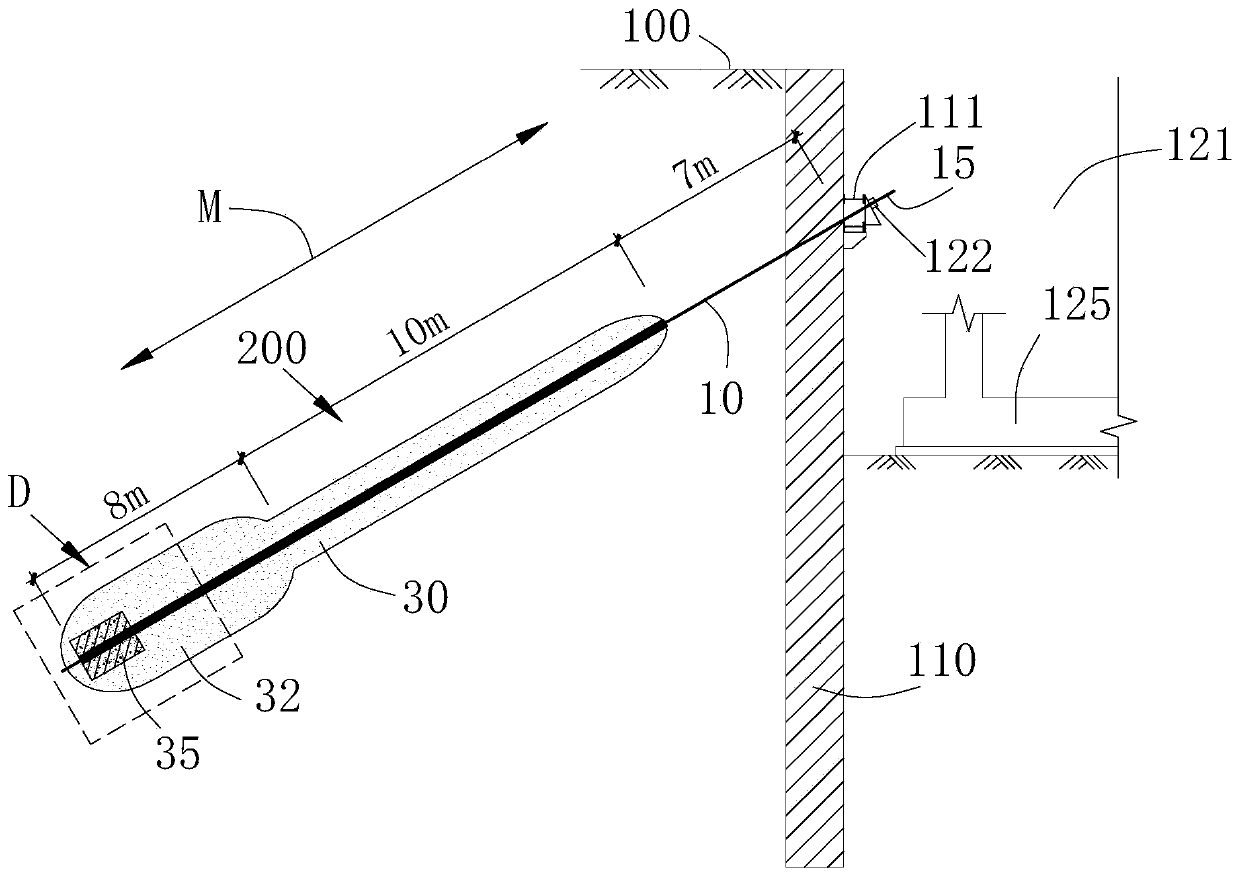

[0047] refer to figure 1 , figure 1 It is a partial view of the underground structure during construction using an embodiment of the present application.

[0048] figure 1 In , the direction of the arrow M marked at the appropriate position indicates the direction of the axis.

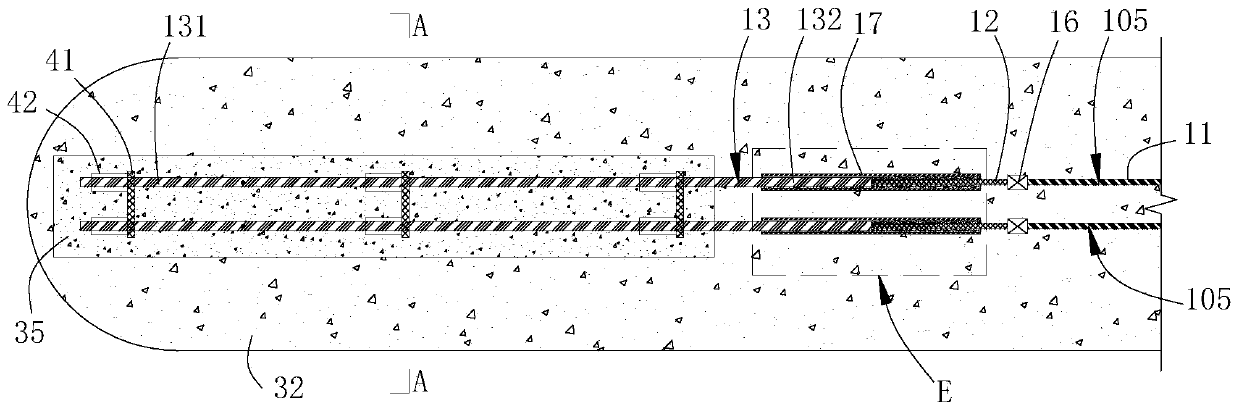

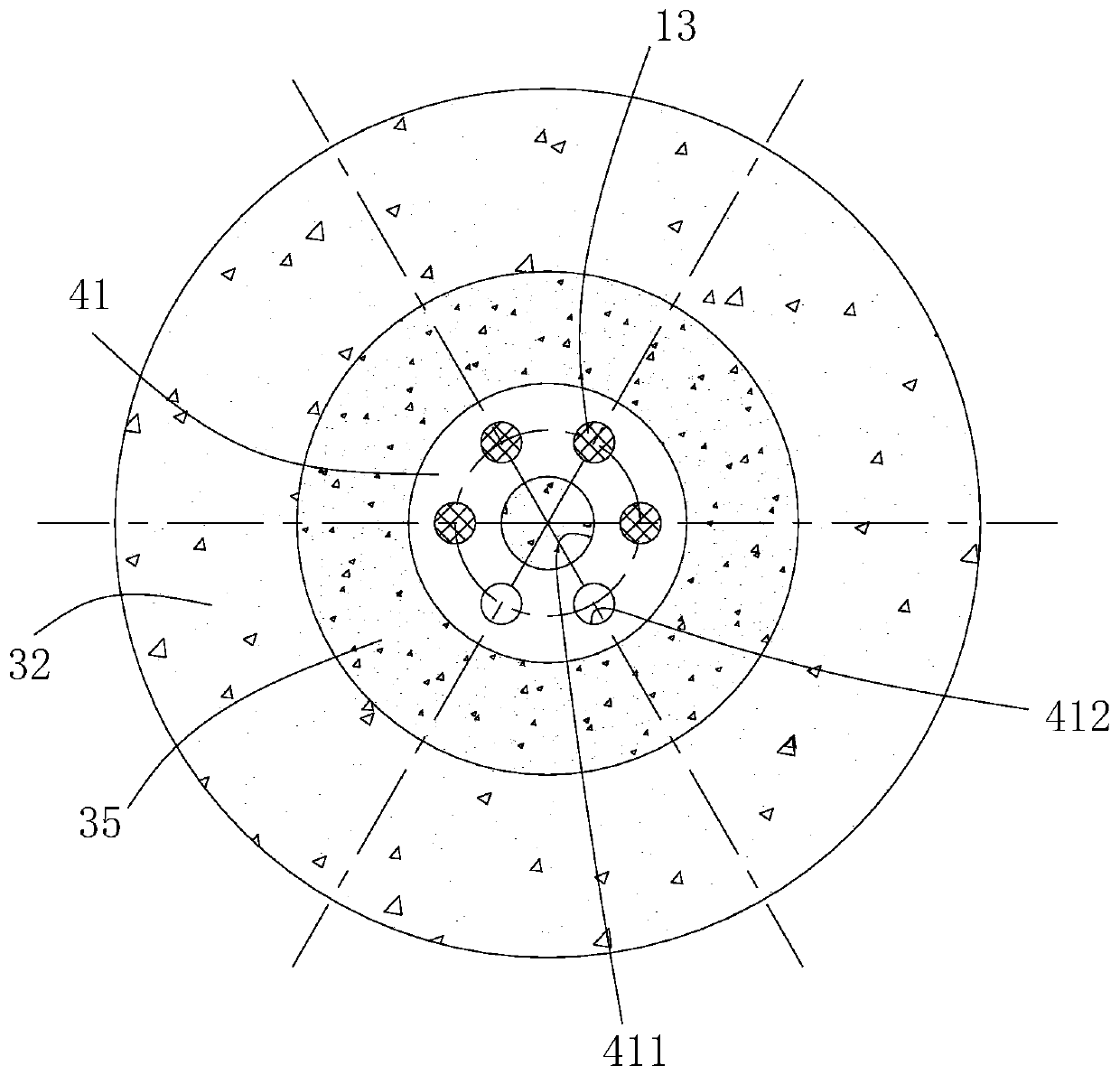

[0049] The recyclable anchor rod 200 is located in the surrounding soil of the foundation pit 121. The recyclable anchor rod 200 includes a cement-soil pile body 30 and an anchor cable 10. The cement-soil pile body 30 extends along the axial direction. The cement-soil pile body The shape 30 has an enlarged head 32.

[0050] One end of the anchor cable 10 is located inside the enlarged head, and the other end of the anchor cable 10 extends along the axis to form an anchor head end 15 , and the anchor head end 15 protrudes from the cement-soil pile body 30 . In this embodiment, the anchor head end 15 is fixed on the purlin 111 with a lock 122 after stretching, and the purlin 111 is erected on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com