A kind of air filter for fast dust removal for automobile engine

A technology of automobile engine and air filter, which is applied in the direction of fuel air filter, engine components, machine/engine, etc., which can solve the problem of shortening the service life of air filter, increasing the maintenance cost of the car owner, increasing the cost of using the car, etc. problem, to achieve the effect of long vibration time, large vibration amplitude and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

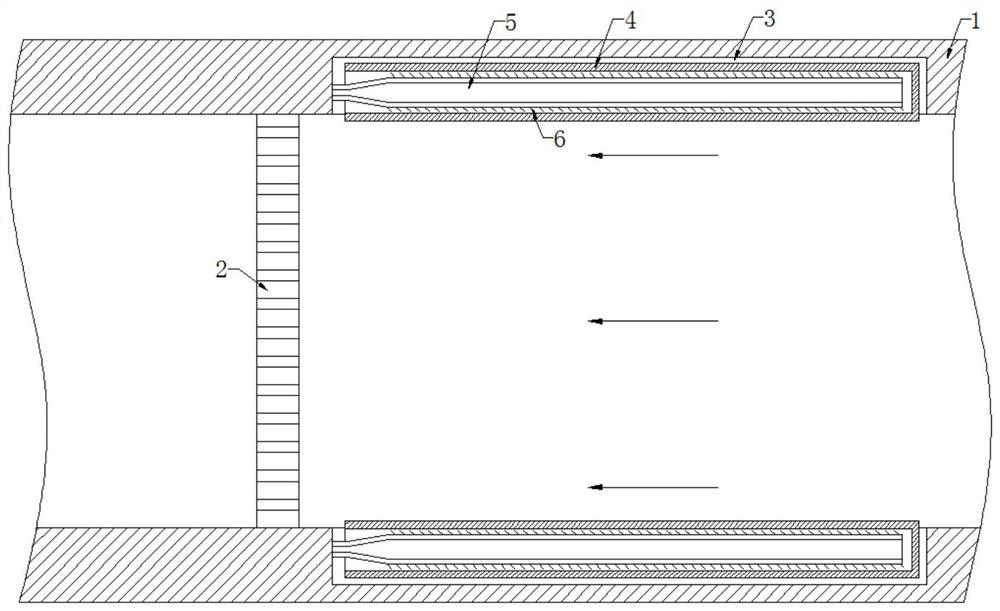

[0023] refer to figure 1 , an air filter for fast dust removal for automobile engines, comprising a casing 1, the inner wall of the casing 1 is fixedly connected with a mesh plate 2, the inner wall of the casing 1 is provided with an annular groove 3, and the inner wall of the annular groove 3 is fixedly connected with one side for sealing The glass ring 4 in the state of the state, further, the sealing of one side of the glass ring 4 can preserve the vibration sound when the engine is started to the greatest extent, the inner wall of the annular groove 3 is fixedly connected with a resonance ring 5, and the side wall of the resonance ring 5 is glued with chemical fiber material 6 , and the chemical fiber material 6 is attached to the inner wall of the glass ring 4. Further, the device is installed vertically at the engine inlet during installation, so that when the engine stops working, the resonance ring 5 no longer vibrates, so that the static electricity on the glass ring 4...

Embodiment 2

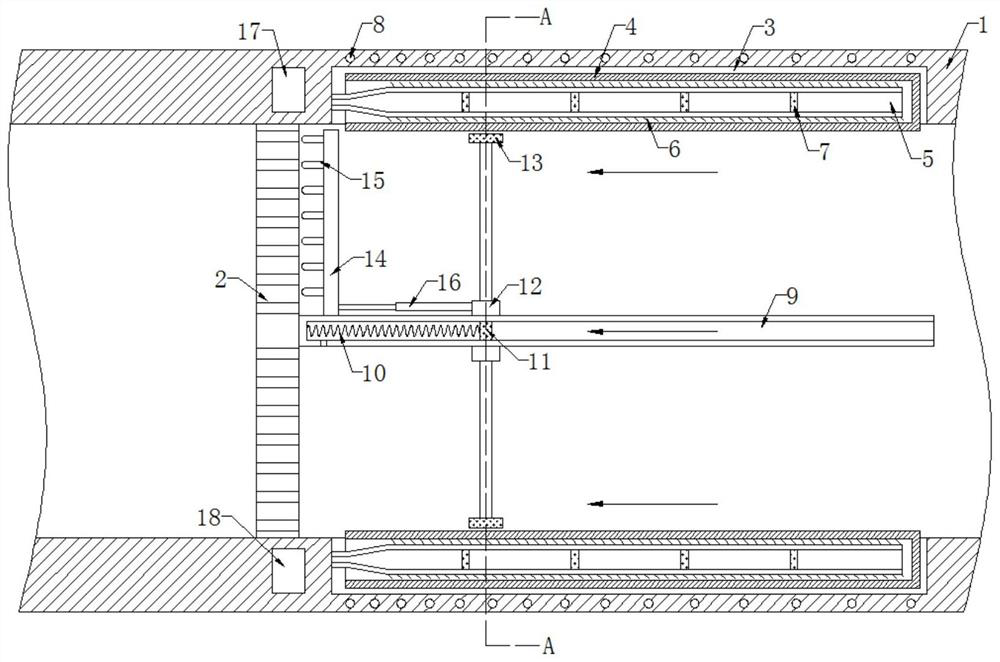

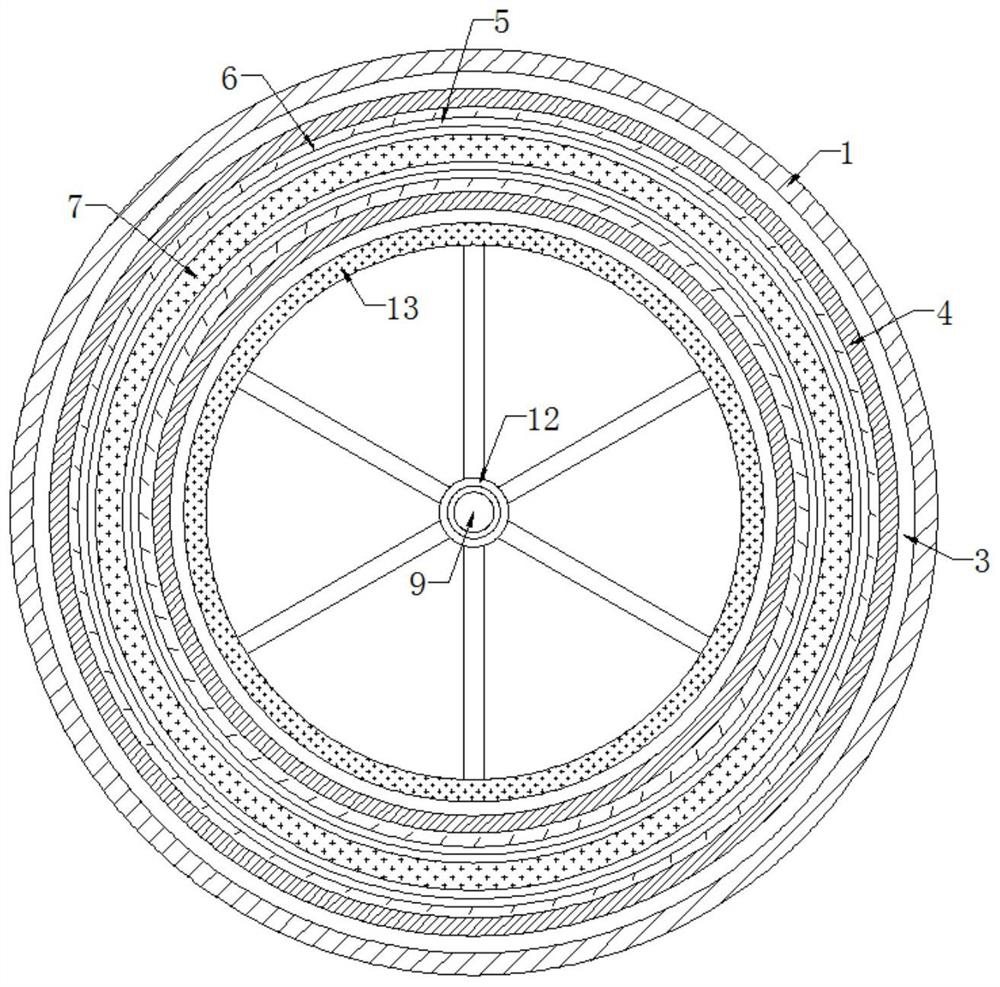

[0026] refer to Figure 2-3 , Different from the first embodiment, the inner wall of the resonance ring 5 is evenly connected with a plurality of magnetic rings 7 with the same magnetic pole directions, and the inner wall of the housing 1 is embedded with induction coils 8 with non-equidistant distribution. Further, the engine is working Vibration will be generated when the resonant ring 5 vibrates, so that the resonant ring 5 drives the magnetic ring 7 to vibrate. At this time, the induction coil 8 reciprocates relative to the magnetic ring 7, and cuts the magnetic induction line, so that the induction coil 8 generates an induced current. A ball screw 9 is fixedly connected to the side wall of the plate 2, and the ball screw 9 has a hollow structure. The inner wall of the ball screw 9 is elastically connected with a magnetic slider 11 through a conductive spring 10. , since the direction of the current passing through the coils of the conductive spring 10 is the same, an attr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com