Test method for compressive strength of rigid leakage plugging materials

A technology of rigid plugging and compressive strength, applied in the direction of applying stable tension/pressure to test material strength, analyzing materials, strength characteristics, etc., can solve problems such as quantitative measurement of compressive strength of materials that cannot be rigidly plugged, and achieve judgment Scientific process, strong operability, reliable and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

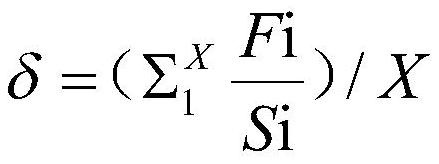

Method used

Image

Examples

Embodiment 1

[0034] In this example, rigid calcium carbonate particle experimental material, which is a rigid plugging material commonly used in oil and gas reservoirs, is selected. First, the following steps are required to determine its optimal loading displacement:

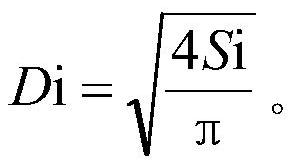

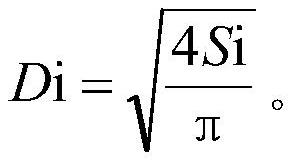

[0035] A, select many grains of rigid calcium carbonate particles at random, and divide it into groups, determine the particle size distribution and average equivalent diameter of each group of rigid calcium carbonate particles by graphical analysis method,

[0036] b. Select one group of rigid calcium carbonate particles and put them on the panel of the pressurized instrument, load them at a constant speed of 0.2mm / min, the loading displacement is 1 / 10 of the average equivalent diameter, and test the rigidity after pressurization by graphic analysis Calcium carbonate particle size distribution, and calculation of D90 degradation rate of rigid calcium carbonate particles before and after pressurization,

[0037] c. The inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com