Operating liquid container comprising built-in system for detecting filling level

A technology of working liquid and filling liquid level, which is applied in the field of measurement system, can solve the problems of damage to the lever sensor, ice block collision, etc., and achieve the effect of increasing long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

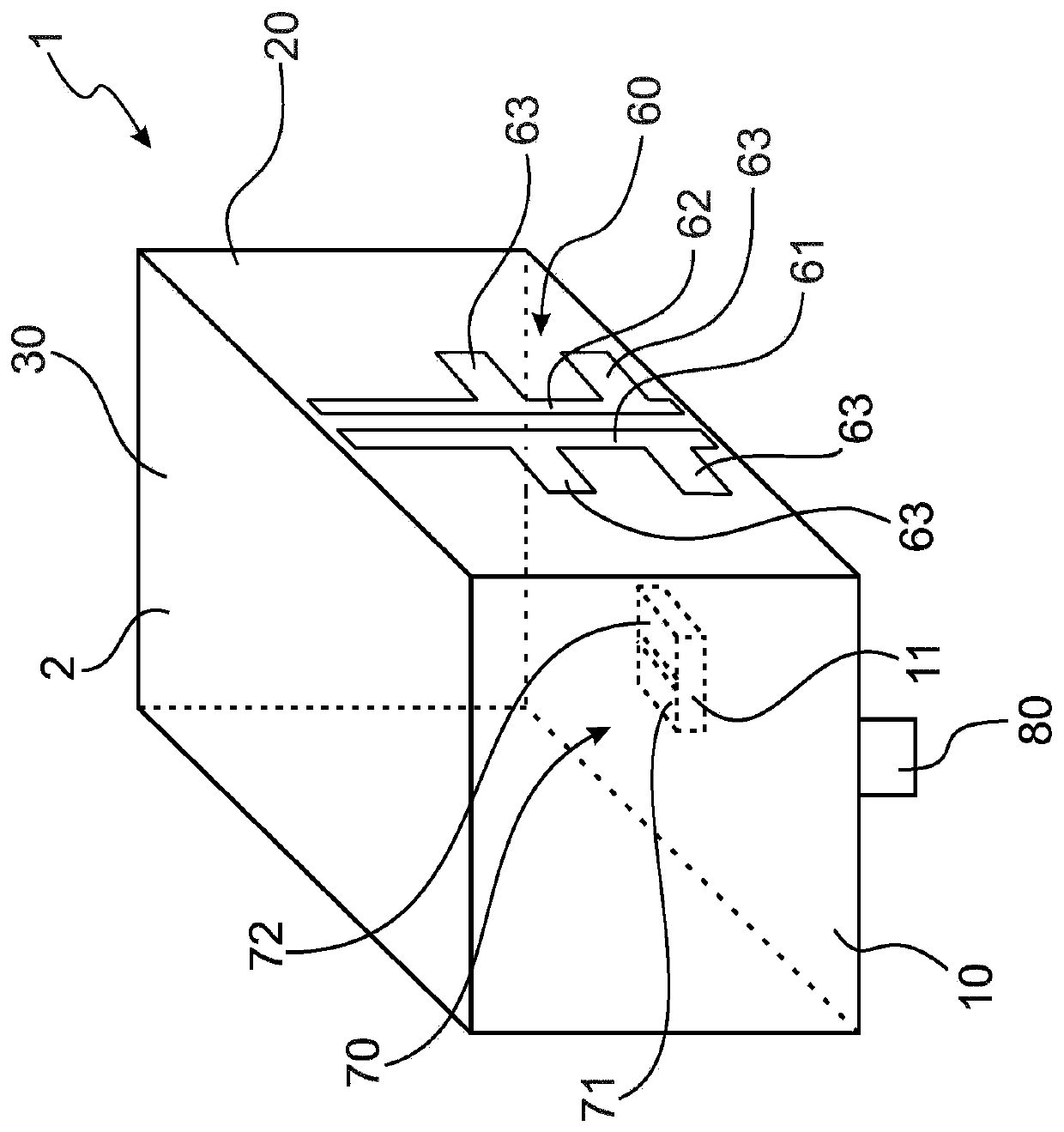

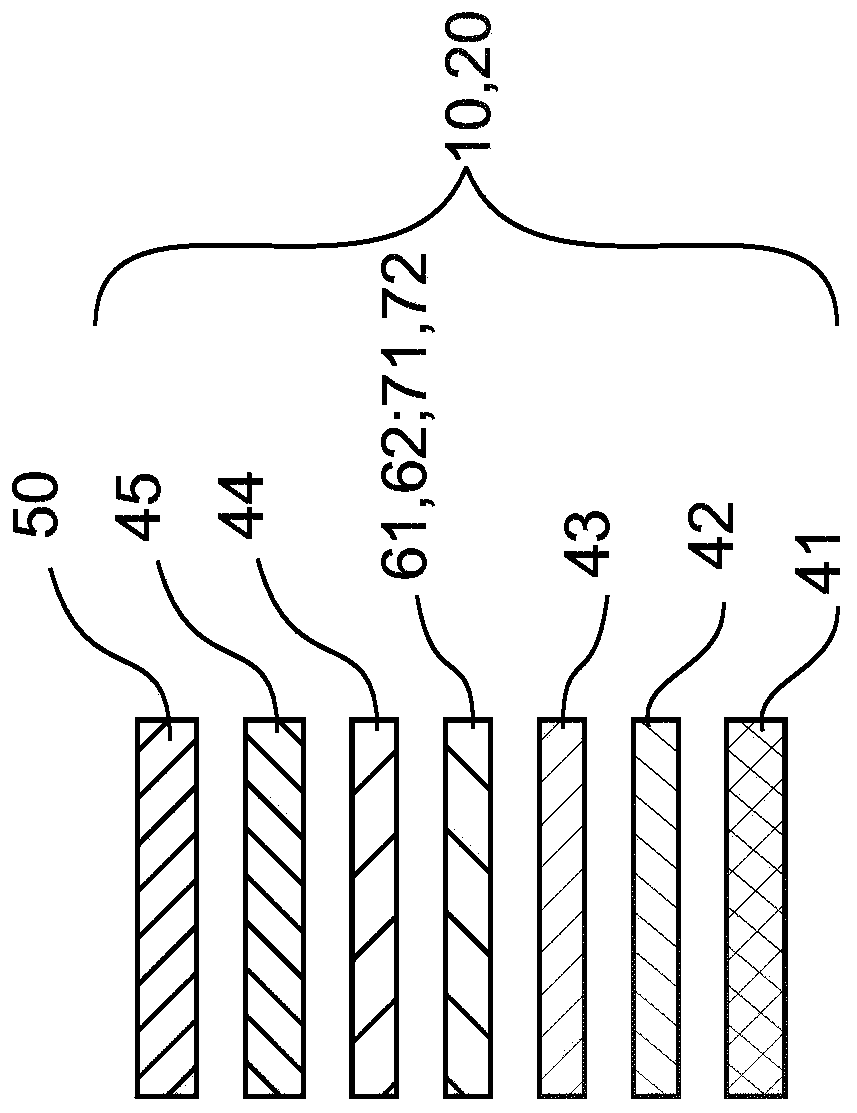

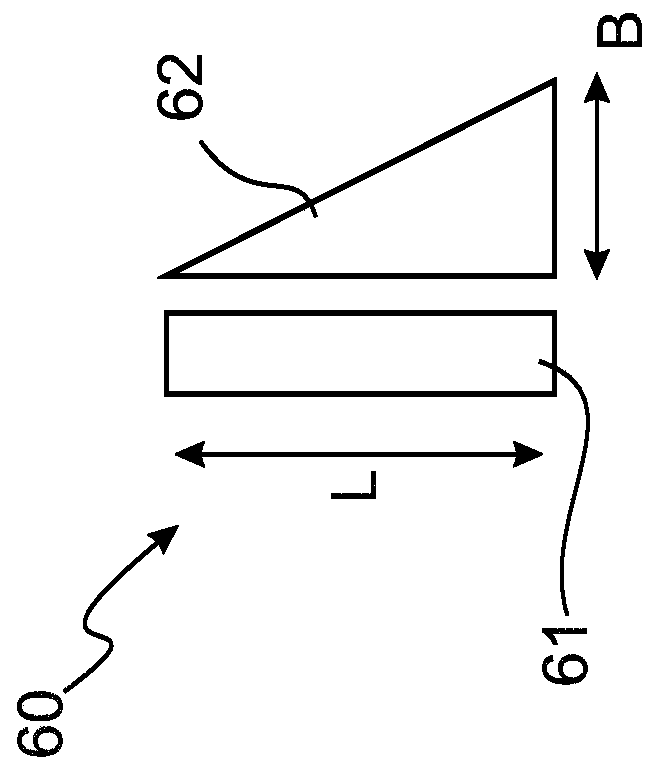

[0095] figure 1 A greatly simplified spatial illustration of a working fluid container 1 according to the invention is shown. The inner space 2 of the working liquid container is defined by a cover wall 30 , a bottom wall 10 and a side wall 20 connecting the bottom wall 10 to the cover wall 30 . figure 1 It is shown that the side wall 20 is designed to be continuous.

[0096] The working fluid container 1 according to the invention has a reference capacitor 70 comprising a first electrode 71 and a second electrode 72 . The first electrode 71 and the second electrode 72 extend parallel to the bottom wall 10 .

[0097] exist figure 1 It can be seen that the bottom wall 10 has a projection 11 extending into the interior 2 of the working fluid container. The reference capacitor 70 is embedded in the bottom wall 10 such that the first electrode 71 and the second electrode 72 of the reference capacitor 70 are embedded in the protrusion 11 of the bottom wall 10 . Therefore, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com