Processing and mixing equipment for pharmaceutical engineering

A technology of mixing equipment and pharmaceutical engineering, applied in the direction of mixers, fluid mixers, chemical/physical processes, etc., can solve problems affecting the mixing process, and achieve the effect of improving mixing efficiency and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

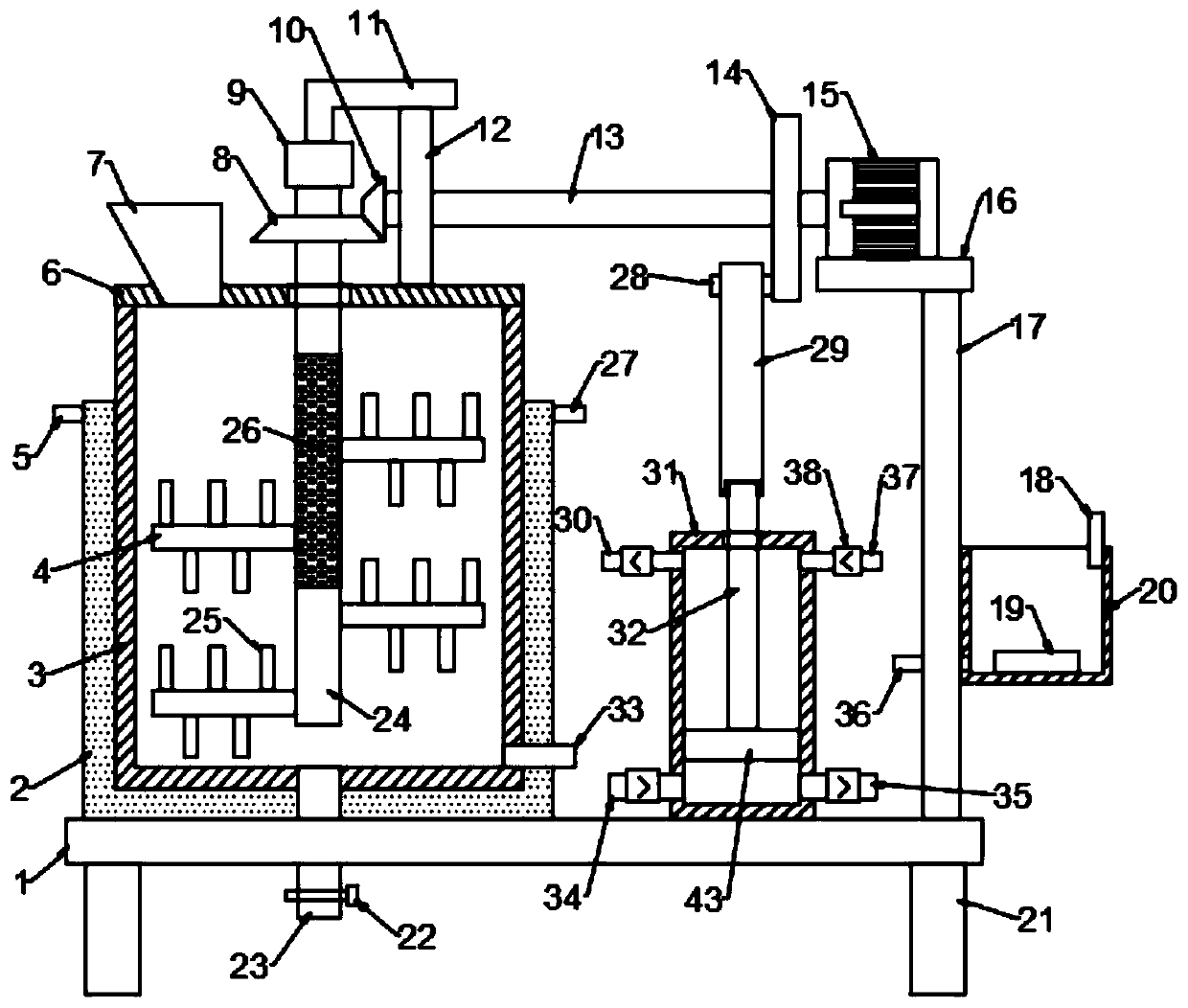

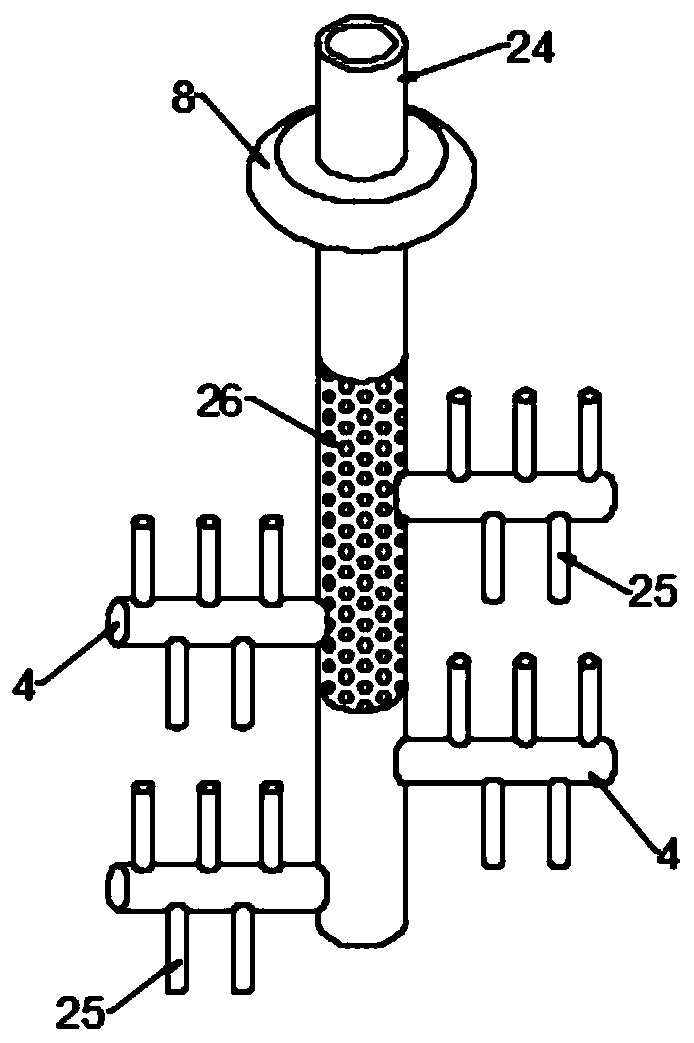

[0027] see Figure 1-2 , in the embodiment of the present invention, a kind of processing and mixing equipment for pharmaceutical engineering includes a bottom plate 1 and a mixing box 3, the bottom of the bottom plate 1 is provided with legs 21, the bottom of the mixing box 3 is provided with a discharge pipe 23, and the discharge pipe 23 is provided with a valve 22; the top of the mixing box 3 is provided with a box cover 6, the box cover 6 is provided with a hopper 7, the outside of the mixing box 3 is provided with a water bath jacket 2, and the water bath jacket 2 is connected with an inlet The water pipe 27 and the water outlet pipe 5, the base plate 1 is fixed with a column 17, the column 17 is equipped with a water tank 20, the water tank 20 is provided with a heater 19, the water tank 20 is connected with a second return pipe 18 and a second suction pipe 36, and the base plate 1 is also provided with a pumping assembly, and the mixing box 3 is provided with an agitati...

Embodiment 2

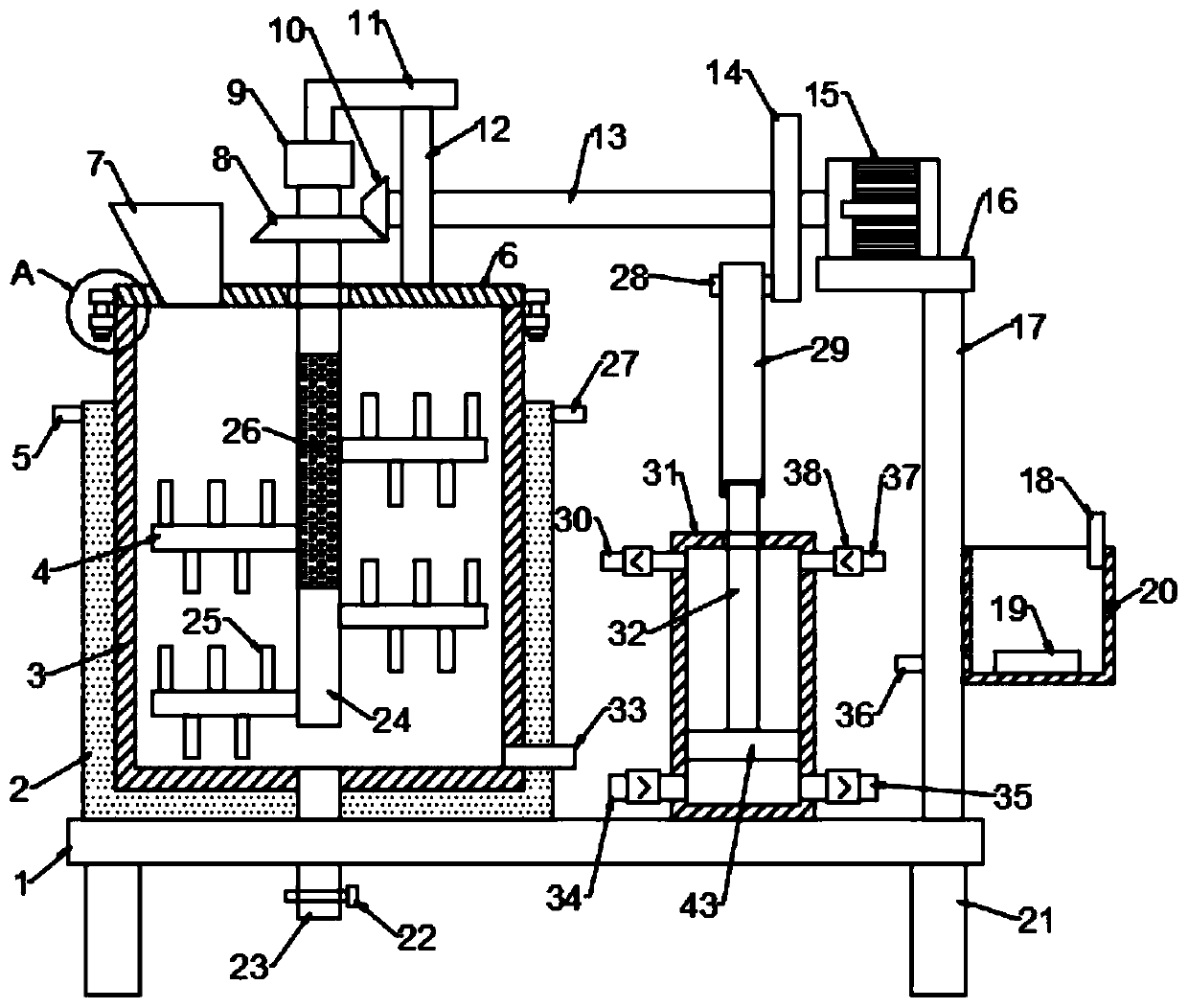

[0038] see Figure 3-4 , in the embodiment of the present invention, a processing and mixing equipment for pharmaceutical engineering is different from embodiment 1 in that a first support block 39 is provided on the box cover 6, and a locking bar is fixed at the bottom of the first support block 39 40, the side wall of the mixing box 3 is provided with a second support block 41, and the second support block 41 is provided with a through hole (not shown in the figure) for the lock rod 40 to pass through, and the lock rod 40 is threaded Nut 42 is arranged; Pass lock bar 40 through the through hole on the second support block 41, tighten nut 42, case lid 6 can be fixedly installed on the mixing box 3, convenient dismounting, so that mixing box 3 cleaning and maintenance of the interior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com